Graphene composite catalyst with good catalytic performance and preparation method thereof

A graphene composite and catalytic performance technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of precious metal particle loss, insufficient surface area, waste of active ingredients, etc., and achieve photocatalysis Effects of improved performance, increased contact area, and improved adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

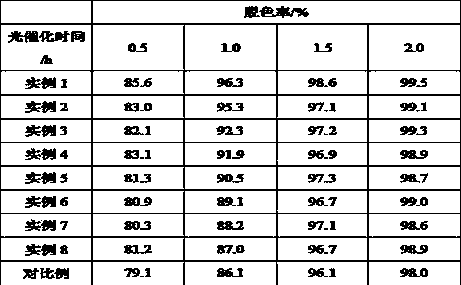

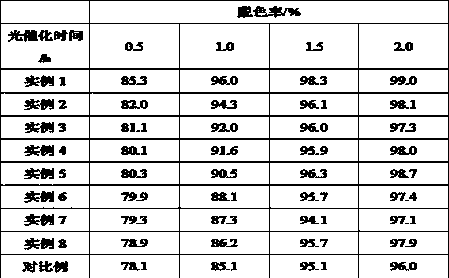

example 1

[0031] Put graphene oxide and deionized water in a three-necked flask at a mass ratio of 1:20, then place the three-necked flask in an ultrasonic disperser, and then add dropwise to the three-necked flask with a mass fraction of 30 % ammonia water to adjust the pH to 7.8, then put the three-necked flask in the digital speed measuring constant temperature magnetic stirrer, then add sodium azide 0.3 times the mass of graphene oxide, heat and stir the reaction, then add tetrahydrochloride 0.03 times the mass of graphene oxide Lithium aluminum hydride was heated and stirred for 2 hours at a temperature of 160°C and a rotation speed of 500r / min, and then filtered to obtain a filter residue. Then, the filter residue was placed in an oven, and dried to a constant weight at a temperature of 110°C to obtain a pre- Processing graphene oxide; by weight, 30 parts of alcohol, 30 parts of acid, 20 parts of petroleum ether, 3 parts of animal oil, 20 parts of tetrabutyl titanate, and 20 parts ...

example 2

[0033] In parts by weight, 30 parts of alcohol, 30 parts of acid, 20 parts of petroleum ether, 3 parts of animal oil, 20 parts of tetrabutyl titanate, and 20 parts of graphene oxide were placed in a four-necked flask at a temperature of 140 ° C. Under the condition of rotating speed of 800r / min, after stirring and reacting at high temperature for 3 hours, a mixed solution was obtained; then, a sodium hydroxide solution with a mass fraction of 30% was added to the four-necked flask to adjust the pH to 8.3, and then titanic acid was added to the four-necked flask An emulsifier with 0.2 times the mass of tetrabutyl titanate and an isocyanate with 0.05 times the mass of tetrabutyl titanate were stirred and mixed for 60 minutes at a rotation speed of ~600r / min to obtain a mixed homogenate; then the mixed homogenate was placed in an autoclave , pressurize to 1.5MPa, under the condition of pressure of 1.5MPa, after keeping the pressure for 50s, release the pressure instantly to obtain...

example 3

[0035] Graphene oxide and deionized water were placed in a three-necked flask at a mass ratio of 1:20, and then the three-necked flask was placed in an ultrasonic disperser. Under the condition of an ultrasonic frequency of 130kHz, a mass fraction of 30% was added dropwise to the three-necked flask. ammonia water to adjust the pH to 7.8, then place the three-necked flask in a digital display speed measuring constant temperature magnetic stirrer, then add sodium azide 0.3 times the mass of graphene oxide, heat and stir the reaction, and then add tetrahydrogenate 0.03 times the mass of graphene oxide Aluminum lithium, heated and stirred for 2 hours at a temperature of 160°C and a speed of 500r / min, filtered to obtain a filter residue, then put the filter residue in an oven, and dried to a constant weight at a temperature of 110°C to obtain a pretreatment Graphene oxide; In parts by weight, 30 parts of water, 30 parts of acid, 20 parts of sherwood oil, 3 parts of animal oil, 20 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com