A kind of immobilized f, n, ag co-doped titanium dioxide photocatalyst and its preparation method and application

A technology of photocatalyst and titanium dioxide, which is applied in the field of photocatalytic materials, can solve the problems of not much co-doping of metal elements and non-metal elements, restricting the popularization and application of photocatalytic technology, difficult to separate, recycle and recycle, etc., to achieve increased photocatalytic Reactive sites, improved photocatalytic efficiency, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

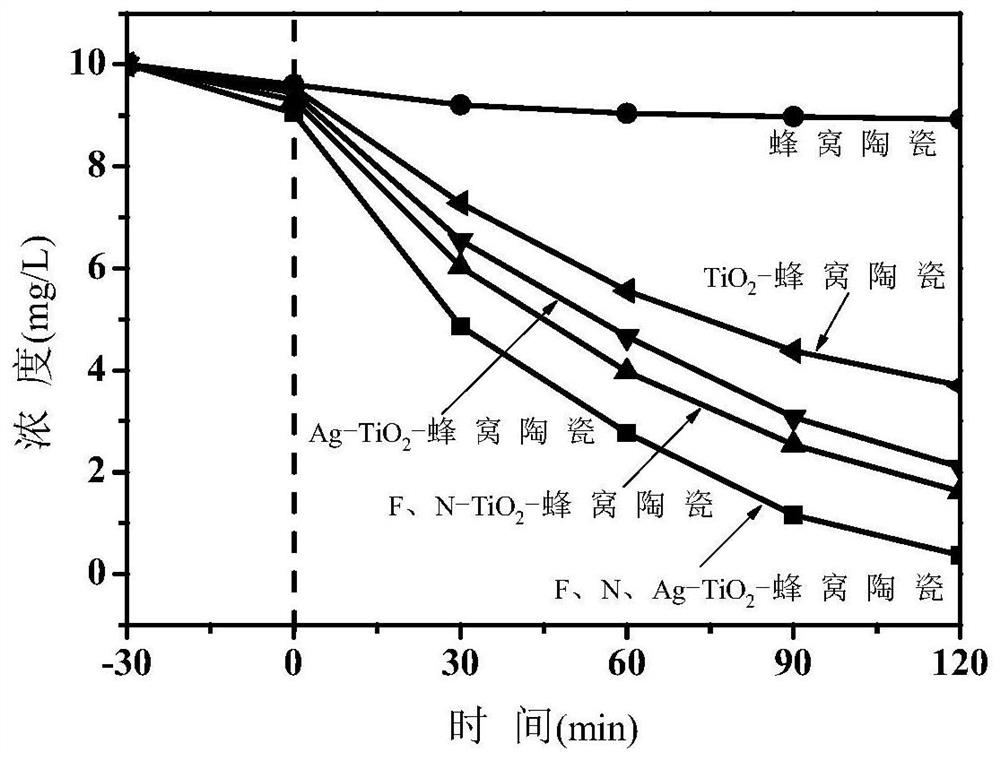

Embodiment 1

[0028] Soak the honeycomb ceramic sample in 10% dilute nitric acid solution for 1 hour, take it out, rinse it with deionized water, dry it in an oven at 80°C for 2 hours, put it in a muffle furnace for calcination at 300°C for 3 hours, and set it aside. Mix tetrabutyl titanate and absolute ethanol uniformly at a volume ratio of 1:2, slowly add 15% glacial acetic acid dropwise under continuous stirring at 700r / min, the volume is 1% of tetrabutyl titanate; then Then add a certain amount of ammonium fluoride solution and silver nitrate solution to the above solution under continuous stirring at 700r / min, so that the molar ratio of F element, N element, Ag element and Ti element in the solution is 1:1:0.01 : 0.5; then the spare honeycomb ceramics were immersed in the solution, and transferred to the hydrothermal reaction kettle, and hydrothermally reacted for 24h at 180°C. After the reaction was completed, the honeycomb ceramics were taken out, washed with deionized water and place...

Embodiment 2

[0030] Soak the honeycomb ceramic sample in 10% dilute sulfuric acid solution for 1 hour, take it out and rinse it with deionized water, then dry it in an oven at 80°C for 2 hours, put it in a muffle furnace for calcination at 800°C for 0.5 hour, and set it aside. Mix titanium tetrachloride and absolute ethanol uniformly at a volume ratio of 1:10, slowly add 10% dilute hydrochloric acid dropwise under continuous stirring at 700r / min, and the volume is 1% of tetrabutyl titanate; then Add a certain amount of ammonium fluoride solution and silver nitrate solution to the above solution under continuous stirring at 700r / min, so that the molar ratio of F element, N element, Ag element and Ti element in the solution is 1:1:0.02: 1; Then immerse the spare honeycomb ceramics in the solution, and transfer them to a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 220°C for 8 hours. After the reaction is completed, take out the honeycomb ceramics, wash them with deioni...

Embodiment 3

[0032] Soak the copper foam sample in 10% dilute hydrochloric acid solution for 1 hour, take it out and rinse it with deionized water, then dry it in an oven at 80°C for 2 hours, put it in a muffle furnace for calcination at 600°C for 1 hour, and set it aside. Mix tetrabutyl titanate and absolute ethanol uniformly at a volume ratio of 1:20, slowly add 15% glacial acetic acid dropwise under continuous stirring at 700r / min, and the volume is 2% of tetrabutyl titanate; then Then add a certain amount of ammonium fluoride solution and silver nitrate solution to the above solution under the continuous stirring state of 700r / min, so that the molar ratio of F element, N element, Ag element and Ti element in the solution is 1:1:0.05 : 2; then the standby foamed copper is immersed in the solution, and transferred to the hydrothermal reaction kettle, hydrothermal reaction 12h at 200 ℃, after the reaction is completed, the foamed copper is taken out, washed with deionized water and placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com