PH-sensitive dual-emission carbon quantum dot and organic composite film thereof, and preparation methods and applications thereof

A technology of carbon quantum dots and composite thin films, which is applied in the field of nanomaterials, can solve problems such as not being easy to capture with the naked eye, limiting the application range of carbon quantum dots, and few reports on double-peak emission carbon quantum dots, etc., to achieve reduced production costs and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method with pH sensitive double-emission carbon quantum dots, comprising the following steps:

[0025] Mixing small organic molecules, an organic nitrogen source and a reaction solvent to obtain a reaction mixture;

[0026] The reaction mixture was subjected to a solvothermal reaction to obtain a crude product;

[0027] The crude product is sequentially filtered, rotary evaporated, dissolved in water and dialyzed to obtain dual-emission carbon quantum dots with pH sensitivity under the excitation of ultraviolet light.

[0028] The invention mixes small organic molecules, organic nitrogen source and reaction solvent to obtain reaction mixture. In the present invention, the ratio of the small organic molecule, the organic nitrogen source and the reaction solvent is preferably 0.05-5g:0.05-5g:5-35mL, more preferably 0.1-2g:0.2-2g:10-25mL, most preferably Preferably it is 0.5:0.5g:10mL.

[0029] In the present invention, the s...

Embodiment 1

[0050] Weigh 0.5 g of anhydrous citric acid and 0.5 g of phenylenediamine, add 10 mL of acetone, and ultrasonically mix for 10 min. The obtained reaction mixture was added to a 30mL polytetrafluoroethylene autoclave, and the reactor was solvent-heated at 160°C for 6h in a homogeneous reactor, and the temperature was raised from room temperature to 160°C at a heating rate of 5°C / min. After the reaction was completed, the reaction kettle was naturally cooled to room temperature, and the crude product was filtered through a filter membrane with a pore size of 0.22 μm, dried by rotary evaporation at 60°C, and then dissolved in water, and dialyzed with a dialysis membrane with a molecular weight cut-off of 500Da for 24 hours to obtain carbon quantum point. After mixing 1mL of 5mg / mL carbon quantum dot aqueous solution with 3mL of 5% polyvinyl alcohol, the carbon quantum dot organic composite film was synthesized at 60°C.

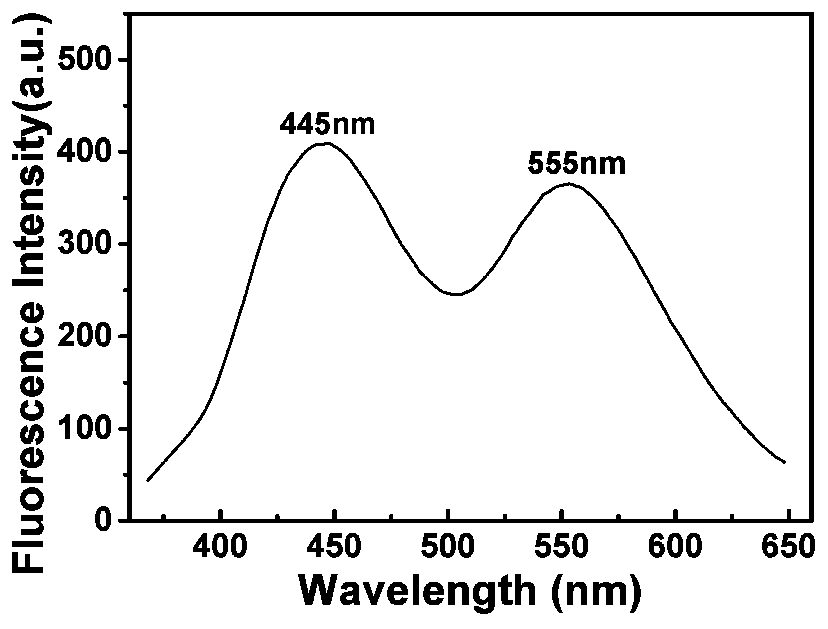

[0051] The carbon quantum dots prepared in this embodiment...

Embodiment 2

[0054] Weigh 0.1g of anhydrous glucosamine and 0.2g of polyethyleneimine, add 10mL of ethanol, and ultrasonically mix for 10min. The obtained reaction mixture was added into a 30mL polytetrafluoroethylene autoclave, and the autoclave was subjected to solvent heat treatment at 210°C for 2 hours in a homogeneous reactor, and the temperature was raised from room temperature to 210°C at a heating rate of 5°C / min. After the reaction was completed, the reaction kettle was naturally cooled to room temperature, and the crude product was filtered through a filter membrane with a pore size of 0.22 μm, dried by rotary evaporation at 60°C, and then dissolved in water, and dialyzed with a dialysis membrane with a molecular weight cut-off of 500Da for 24 hours to obtain carbon quantum point.

[0055] After testing, the carbon quantum dots emit blue fluorescence under ultraviolet light and have low cytotoxicity to Hepg2 cells. They have been successfully used in Hepg2 cell imaging and emit g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com