A kind of organic furfuryl alcohol modified amino resin-inorganic sol composite coating for casting filter screen, preparation method and application

An amino resin, inorganic sol technology, applied in textiles and papermaking, etc., can solve the problems of inability to meet the requirements of high temperature use of filters, methanol pollution of the workshop environment, poor heat resistance, etc. Low smoke and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a kind of preparation method of the organic furfuryl alcohol modified amino resin-inorganic sol composition that is used for casting filter screen, comprising:

[0044] Mix appropriate amount of water or furfuryl alcohol or low-condensation furfuryl alcohol with sol or solid sol, then add furfuryl alcohol modified amino resin or amino resin and mix evenly, then add appropriate amount of additives or other auxiliary materials and mix evenly.

[0045] The present invention also provides a method for preparing an organic furfuryl alcohol-modified amino resin-inorganic sol composite coating for a filter screen for casting, wherein alkali-free glass fibers or high-silica glass fibers are impregnated in the above-mentioned composition, Finally, after solidification or / and carbonization, an organic-inorganic coating is formed on the glass fiber cloth to obtain a filter net for casting.

[0046] Coating material preparation: water or furfuryl...

Embodiment 1

[0053] (1) Synthesis of low free aldehyde melamine formaldehyde resin: Add 90 grams of water and 55.3 grams of paraformaldehyde to the there-necked bottle, heat up to 80°C to dissolve, add 63 grams of melamine, react at 80°C for 0.5 hours, pH is 8 to 9, add 120 grams of methanol, adjust the pH to 5 to 6, the temperature is 50 ° C, keep the reaction for 0.5 hours, and adjust the pH to 8-9 with liquid caustic soda.

[0054] (2) Organic-inorganic coating composition:

[0055] Wherein, low free aldehyde melamine formaldehyde resin: 30g (solid content about 35%);

[0056] Furfuryl alcohol: 35g

[0057] The curing agent is maleic anhydride: 2g

[0058] Alkaline silica sol (40%): 33g

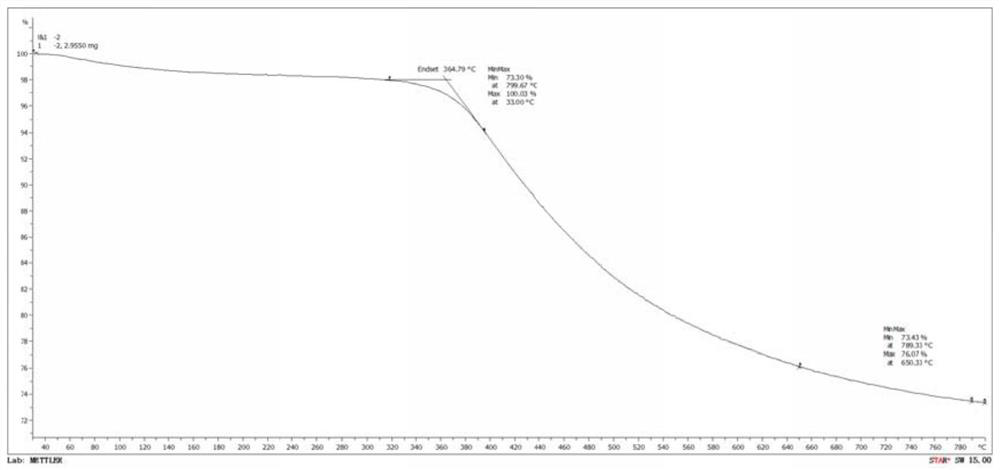

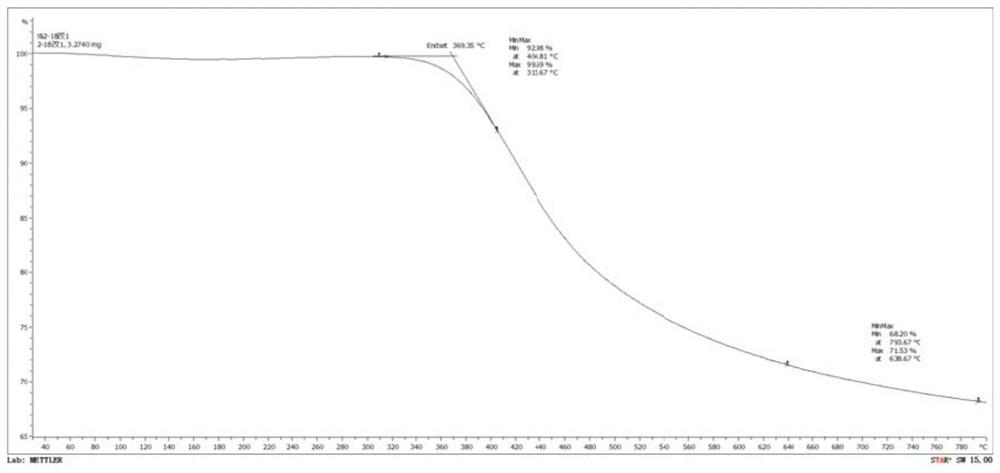

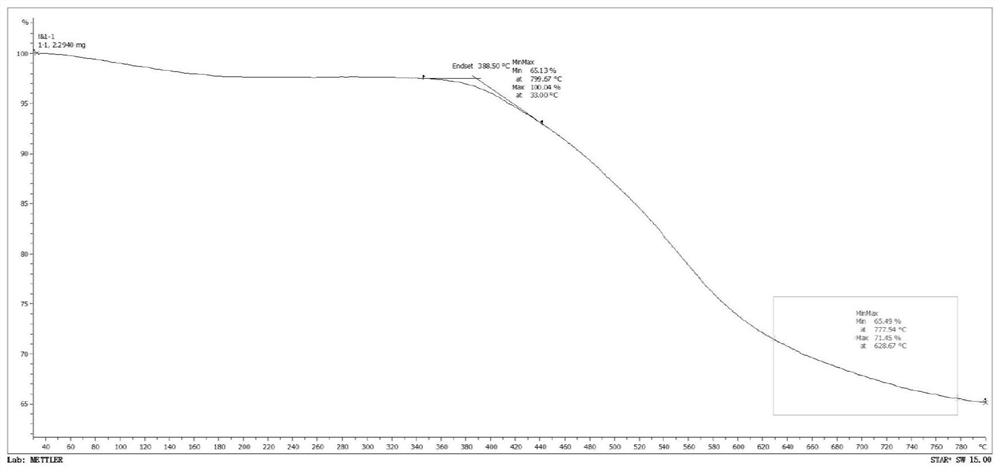

[0059] (3) The organic-inorganic composite coating material is cured and carbonized at 150°C and 300°C for a certain period of time, and the carbonization rate and thermogravimetric curve of the carbide are measured;

[0060] (4) Dip coating in the above-mentioned coating material with alkali-free ...

Embodiment 2

[0062] (1) Synthesis of furfuryl alcohol modified melamine formaldehyde resin: Add 150g of 37% liquid formaldehyde and 50g of furfuryl alcohol into a three-necked flask with a condenser and a stirring device, start stirring, adjust the pH to 8.5-9 with liquid alkali, and then add 63g of melamine , raise the temperature to 70°C, after the melamine is dissolved, react for another 20 minutes, cool down to about 65°C, add 55g of methanol and 80g of furfuryl alcohol, adjust the pH to 5.0-5.5 with dilute hydrochloric acid, and finally keep the reaction at 90°C for about 30 minutes, and discharge;

[0063] (2) Organic-inorganic coating composition:

[0064] Wherein, furfuryl alcohol modified melamine formaldehyde resin: 200g;

[0065] The curing agent is maleic anhydride: 10g;

[0066] water: 20;

[0067] Aluminum sol powder: 52g;

[0068] (3) The organic-inorganic composite coating material is cured and carbonized at 150°C and 300°C for a certain period of time, and the carboniza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com