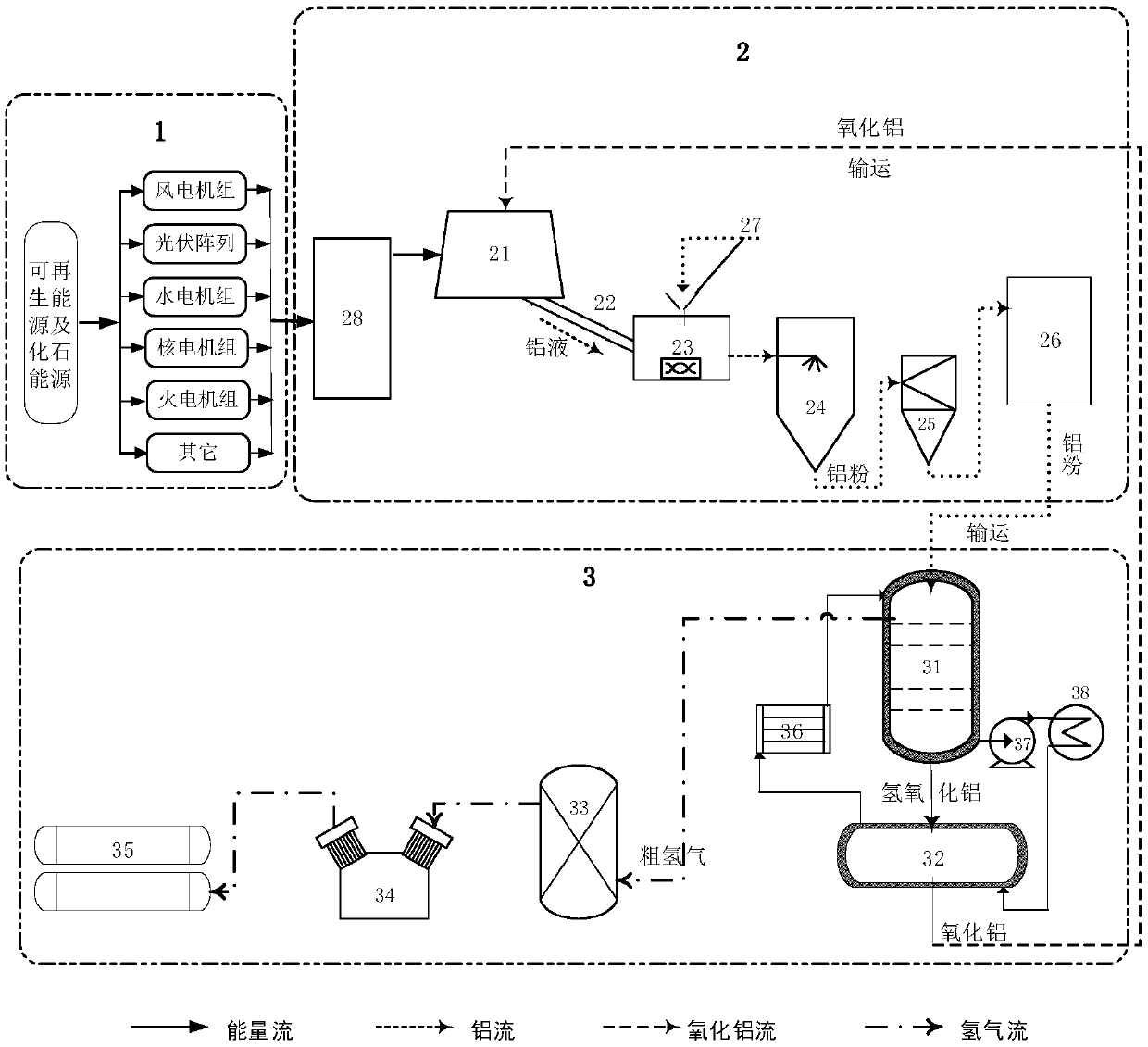

Aluminum water hydrogen production system and method capable of circularly and comprehensively utilizing electric energy to electrolyze aluminum

A hydrogen production system and cyclic technology, applied in the direction of hydrogen production, energy input, etc., can solve the problems of insufficient mixing of raw materials, damage to fuel cell stacks, uneven aluminum hydrolysis rate, etc., to avoid high energy consumption and Complexity of equipment, avoidance of hydrogen purification problems, and avoidance of the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

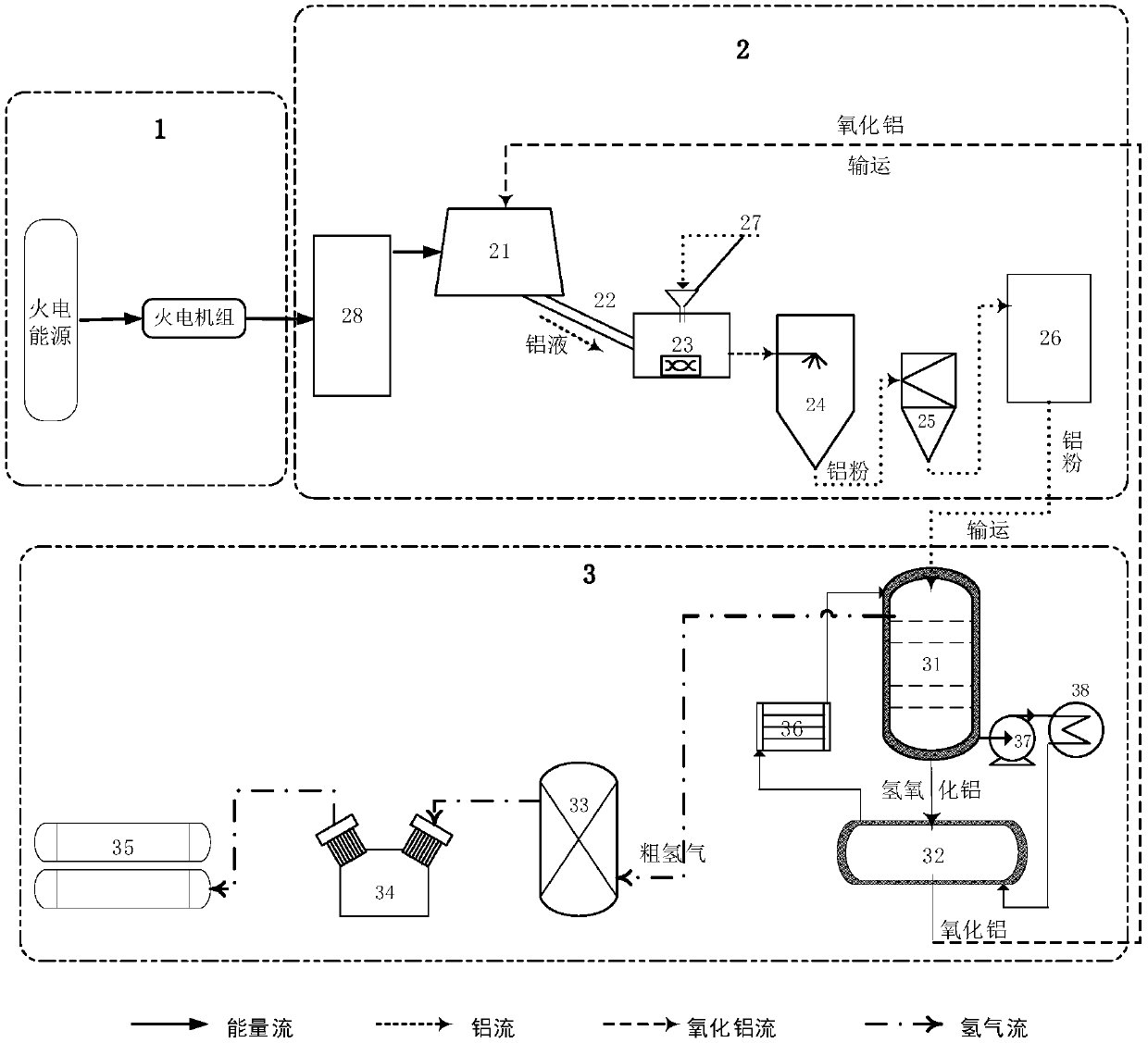

Embodiment 1

[0090] Embodiment 1 of the present invention provides a hydrogen production method, such as figure 2 As shown, the traditional thermal power generation is used as the power supply. After the electric energy is transformed and rectified, the aluminum oxide is added to the aluminum electrolytic tank 21 to be electrolyzed into aluminum liquid, and then directly sent to the atomization furnace 23 through the liquid guide tank 22. At the same time, the mass The powder corrosion inhibitor with a ratio of 0.5wt.% to 30wt.% is fed into the atomization furnace 23 through the automatic feeder 27 to melt and fully mixed with the aluminum liquid under the agitation of the mixer, and then sent to the nitrogen atomization device Atomized and cooled in 24 to form composite aluminum powder, then classified and collected by aluminum powder grading device 25, then sent to aluminum powder vacuum packaging machine 26 for vacuum packaging by air knife plug flow type dense-phase pneumatic conveying...

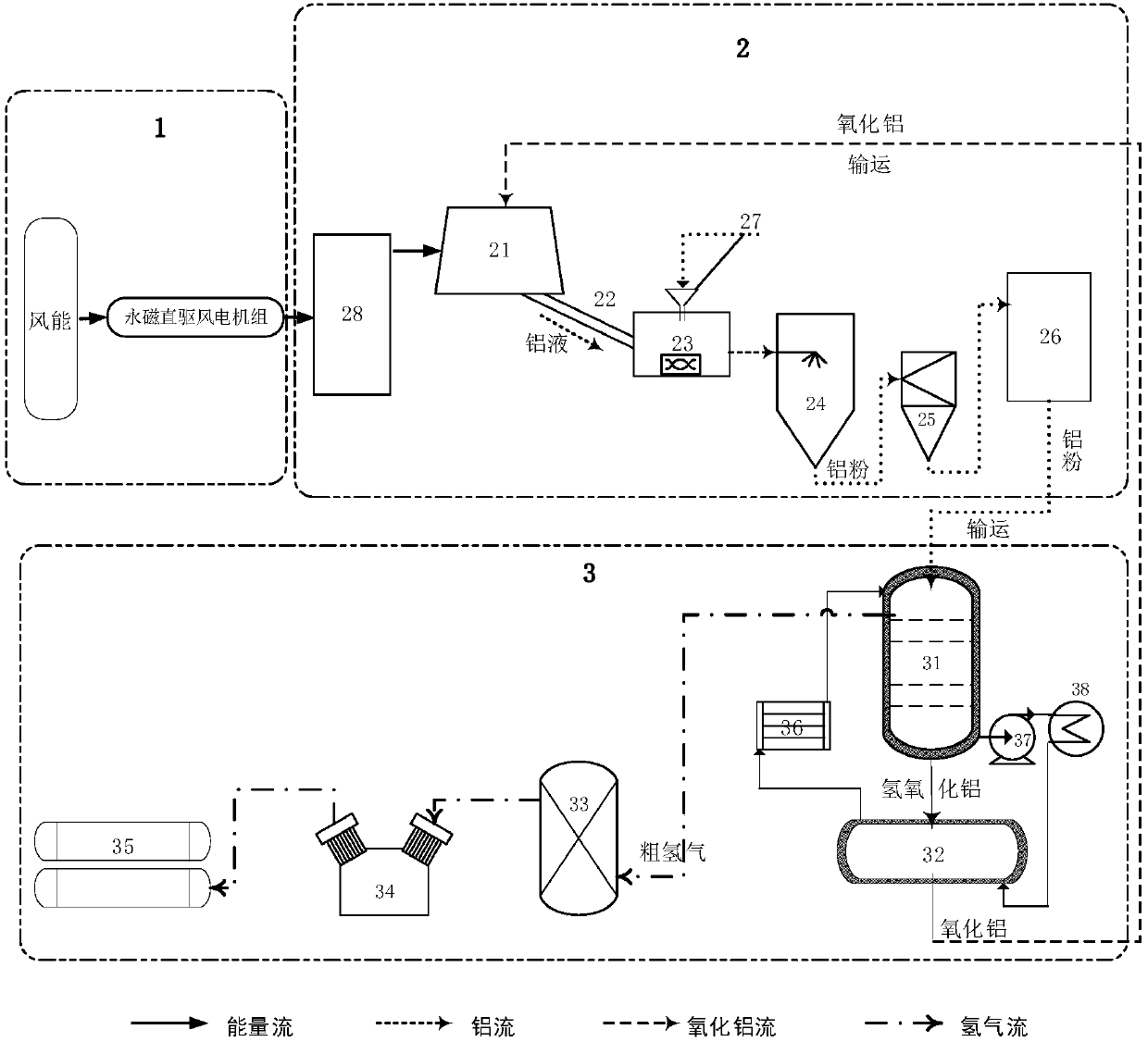

Embodiment 2

[0092] Embodiment 2 of the present invention provides a hydrogen production method, such as image 3 As shown, the wind power generated by the wind field of the permanent magnet direct-drive wind turbine is used as the power supply, after the transformation and rectification, the aluminum oxide is added to the aluminum electrolytic tank 21 and electrolyzed to form aluminum liquid, which is then directly sent to the atomization furnace through the liquid guide tank In 23, at the same time, the boehmite powder with a mass ratio of 30wt.% is added to the atomization furnace 23 through the automatic feeder 27 to melt and fully mixed with the aluminum liquid under the agitation of the stirrer, and then fed into the nitrogen mist Atomized and cooled in the atomization device 24 to form composite aluminum powder, then classified and collected by the aluminum powder classification device 25, and then sent to the aluminum powder vacuum packaging machine 26 for vacuum packaging by the ai...

Embodiment 3

[0094] Embodiment 3 of the present invention provides a hydrogen production method, such as Figure 4 As shown, the wind power generated by the wind farm of the doubly-fed asynchronous wind turbine is used as the main power supply, and the thermal power of the coal-fired thermal power plant is used as the auxiliary power. After the transformation and rectification, aluminum oxide is added to the aluminum electrolytic tank 21 and electrolyzed into aluminum liquid. After that, it is directly sent to the atomization furnace 23 through the liquid guide tank 22, and at the same time, the corundum powder with a mass ratio of 25wt.% is added to the atomization furnace 23 through the automatic feeder 27 to be melted and mixed with the aluminum liquid under the agitation of the mixer. Fully mixed, then sent to the nitrogen atomization device 24 for atomization and cooling to form composite aluminum powder, then classified and collected by the aluminum powder classification device 25, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com