Preparing method and application of super hydrophobic coating with photothermal effect

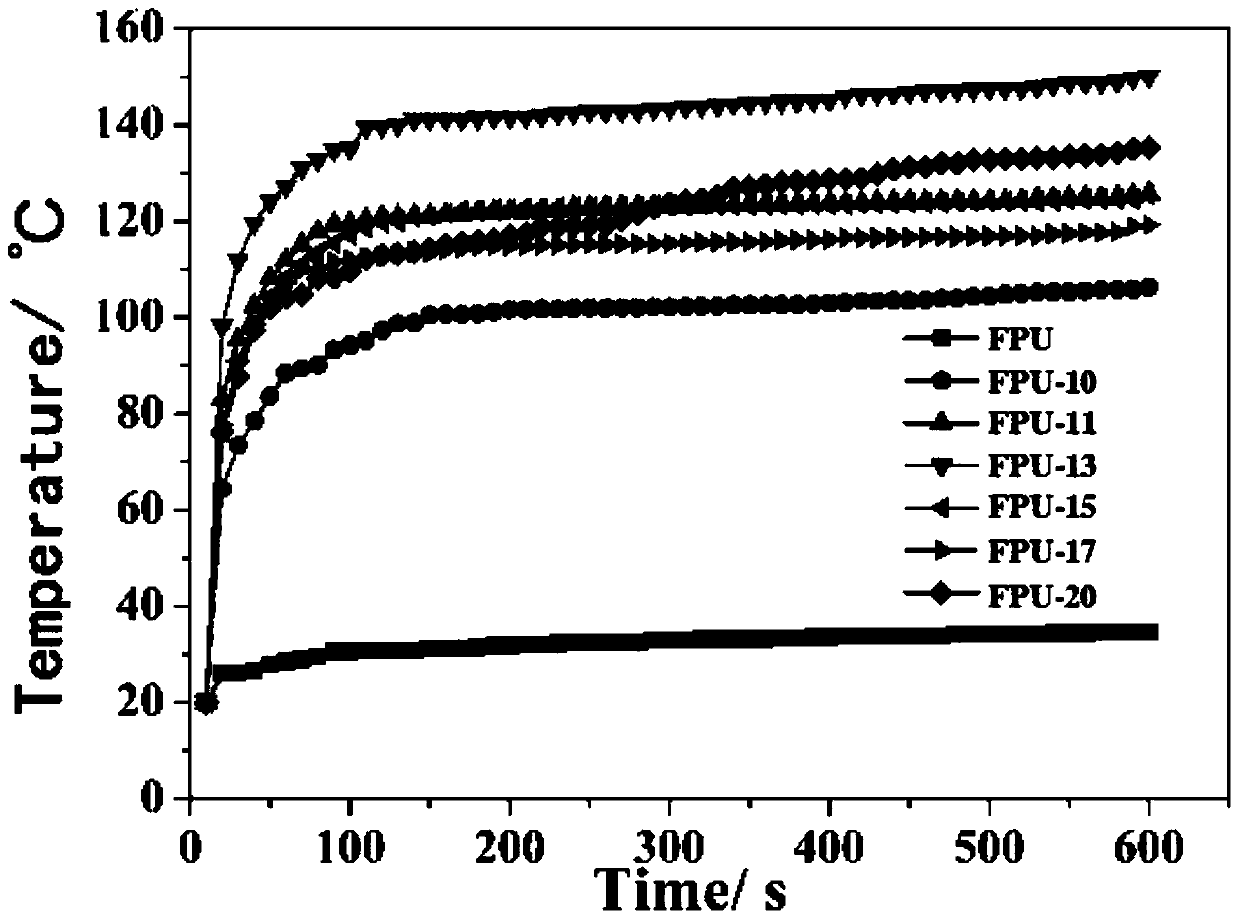

A technology of super-hydrophobic coating and photothermal effect, which is applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problem that it is difficult to realize the preparation of large-area super-hydrophobic coating, the anti-icing of the super-hydrophobic surface is not very ideal, and cannot last for a long time Solve problems such as icing, achieve excellent photothermal effects, improve anti-icing and deicing performance, and reduce surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Embodiments of the present invention provide a method for preparing a superhydrophobic coating with a photothermal effect, comprising the following steps:

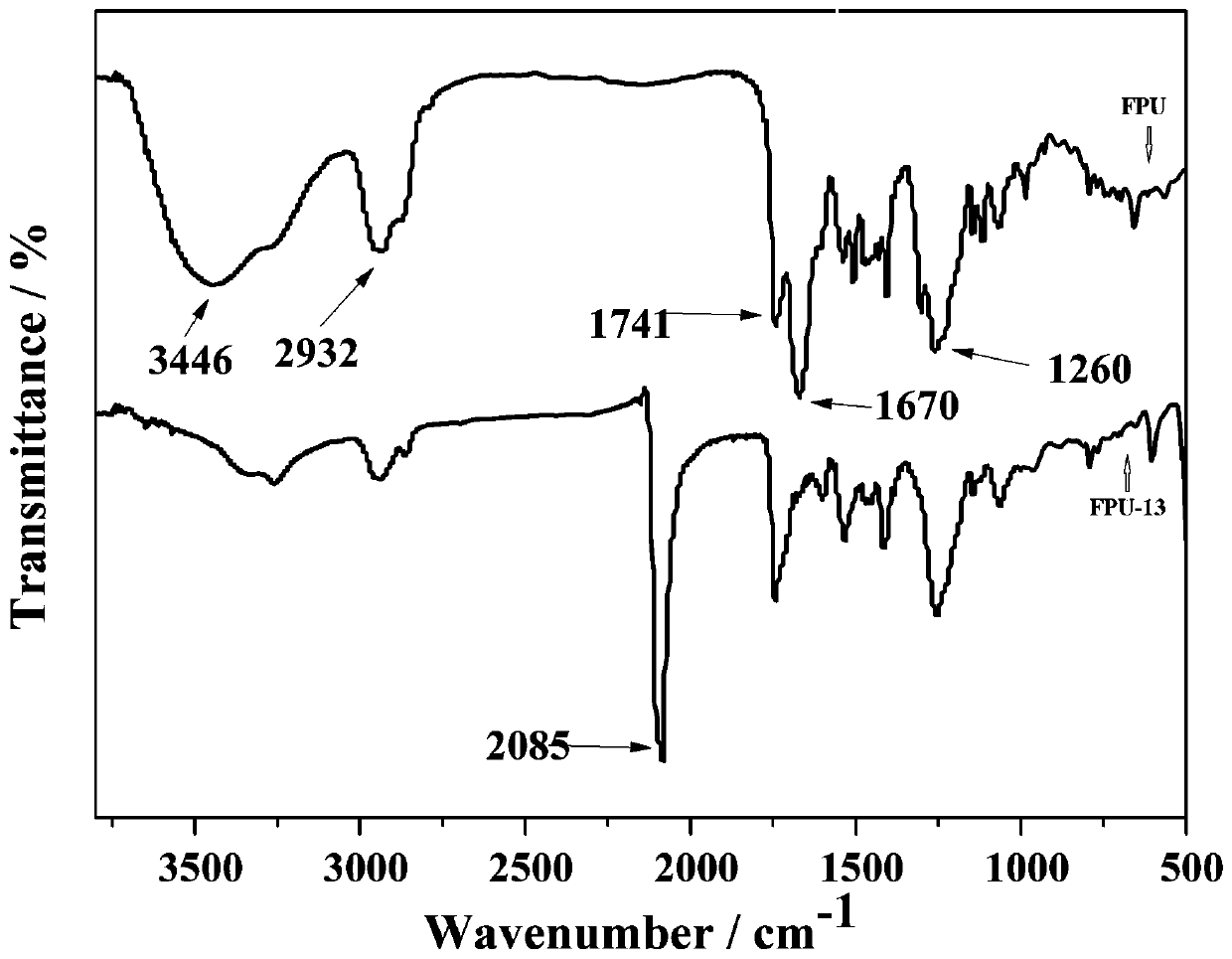

[0019] (1) Synthesis of fluorinated polyurethane: polycarbonate diol (abbreviated as PCDL) and toluene diisocyanate (abbreviated as TDI) after dewatering are synthesized into a prepolymer under the catalysis of dibutyltin dilaurate (abbreviated as DBTDL). The prepolymer reacts with perfluorooctyl alcohol to obtain fluorinated polyurethane;

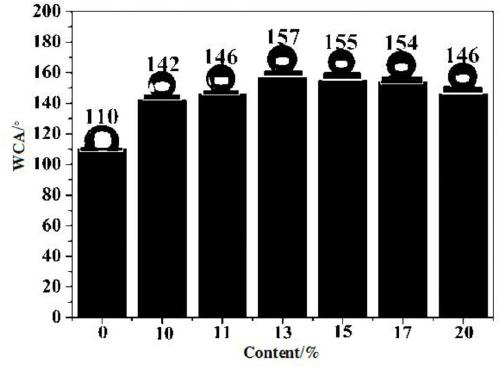

[0020] (2) After the fluorinated polyurethane and Prussian blue prepared in the step (1) are uniformly dispersed by ultrasonic waves, they are coated or sprayed on the substrate, and dried to obtain a super-hydrophobic coating.

[0021] In the present invention, the mol ratio of toluene diisocyanate and polycarbonate diol in step (1) is 2~5:1; By controlling the add-on amount of toluene diisocyanate and polycarbonate diol, to guarantee more sufficient synthesis preparation aggr...

Embodiment 1

[0034] Embodiment 1 of the present invention provides a kind of preparation method of superhydrophobic coating with photothermal effect, wherein, the synthetic route of fluorinated polyurethane is as follows:

[0035]

[0036] This preparation method comprises the steps:

[0037] (1) Synthesis of fluorinated polyurethane: adding polycarbonate diol 5g and toluene diisocyanate 1.306g after dehydration in the four-necked flask equipped with mechanical stirrer, thermometer, condenser, drying tube and nitrogen inlet, and then to Add 0.02 g of dibutyltin dilaurate into the flask as a catalyst, heat the mixture in an oil bath to 80°C under the condition of stirring and nitrogen protection, keep the temperature constant, and react polycarbonate diol and toluene diisocyanate at this temperature for 2 hours to obtain Prepolymer: keep the temperature constant, add 1.821g of perfluorooctyl alcohol to the prepolymer, and continue to react the prepolymer and perfluorooctyl alcohol at 80°...

Embodiment 2

[0040] Example 2 of the present invention provides a method for preparing a superhydrophobic coating with a photothermal effect. The preparation method is the same as in Example 1, except that the amount of Prussian blue added in step (2) is 1.1 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com