Composite material with carbon layer loaded on surface of inorganic carrier and preparation method of composite material

An inorganic carrier and composite material technology, which is applied in the fields of nanotechnology, nanotechnology, and nanotechnology for materials and surface science to achieve the effect of simple and reliable preparation process, low price, and industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

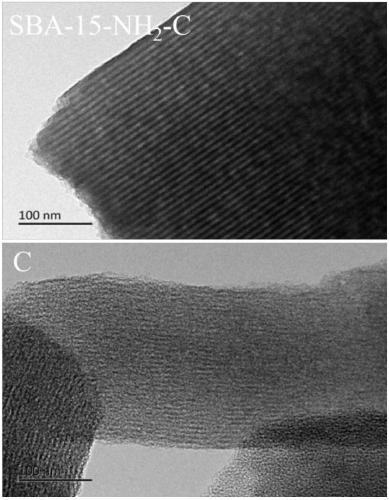

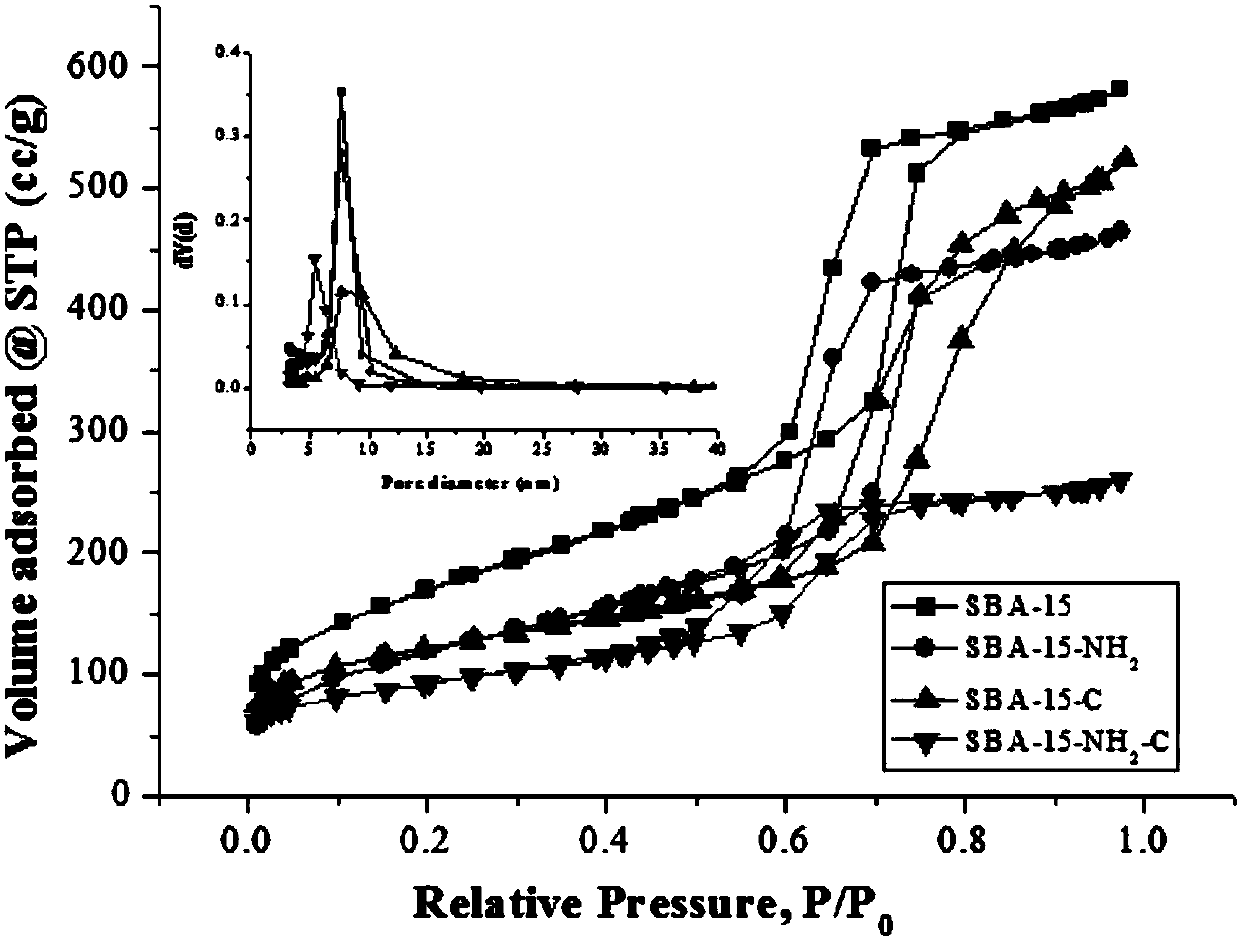

[0037] The composite material of rod-shaped molecular sieve SBA-15 surface coated with carbon layer is prepared, and the preparation steps are as follows:

[0038] Weigh 4g SBA-15 (the specific surface area is 613.56m 2 / g, the average pore diameter is 7.74nm) was put into an oven and dried at 120°C for 12 hours, placed in a 100mL glass flask filled with 40mL of anhydrous toluene under a nitrogen atmosphere, stirred evenly by magnetic force, and added 4.8mL of 3-aminopropyl Trimethoxysilane, stirred and refluxed at 110°C for 12 hours, filtered under reduced pressure and washed with anhydrous toluene, dichloromethane, methanol, water, methanol in sequence, and dried at 80°C to constant weight to obtain the aminated mesoporous support . Put the above-mentioned aminated mesoporous carrier in a 500 mL hydrothermal kettle lined with polytetrafluoroethylene, add 12g of glucose and 200mL of water in sequence, stir evenly, tighten the reaction kettle, and place it in a heating device...

Embodiment 2

[0040] The composite material of rod-shaped molecular sieve SBA-15 surface coated with carbon layer is prepared, and the preparation steps are as follows:

[0041] Weigh 4g SBA-15 (the specific surface area is 613.56m 2 / g, the average pore diameter is 7.74nm) put it in an oven and dry at 100°C for 1 hour, place it in a 100mL glass flask filled with 10mL anhydrous toluene under nitrogen atmosphere, stir it evenly with magnetic force, add 0.4mL 3-aminopropyl Triethoxysilane, stirred and refluxed at 80°C for 12 hours, filtered under reduced pressure and washed with anhydrous toluene, dichloromethane, methanol, water, methanol in sequence, and dried at 60°C to constant weight to obtain aminated mesoporous carrier. Put the above-mentioned aminated mesoporous carrier in a 500mL hydrothermal kettle lined with polytetrafluoroethylene, add 2g of glucose and 20mL of water in sequence, stir evenly, tighten the reaction kettle, and place it in a heating device at 140°C for 2 hours. The...

Embodiment 3

[0043] The composite material of rod-shaped molecular sieve SBA-15 surface coated with carbon layer is prepared, and the preparation steps are as follows:

[0044] Weigh 4g SBA-15 (the specific surface area is 613.56m 2 / g, the average pore diameter is 7.74nm) put it in an oven and dry at 160°C for 12 hours, place it in a 250mL glass flask filled with 80mL of anhydrous toluene under a nitrogen atmosphere, stir it evenly by magnetic force, add 20mL N-(β-ammonia Ethyl-γ-aminopropyl)methyldimethoxysilane, stirred and refluxed at 120°C for 12 hours, filtered under reduced pressure and washed successively with anhydrous toluene, dichloromethane, methanol, water, methanol, and dried at 150°C The aminated mesoporous carrier can be obtained under the condition of constant weight. Place the above-mentioned aminated mesoporous carrier in a 500mL hydrothermal kettle lined with polytetrafluoroethylene, add 40g of glucose and 200mL of water in sequence, stir evenly, tighten the reaction k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Carbon layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com