Electrocatalytic oxidation treating method and system of cyanide-containing wastewater

An electrocatalytic oxidation and treatment system technology, which is applied in the field of electrocatalytic oxidation treatment methods and systems for cyanide-containing wastewater, can solve the problems of rising chemical raw material prices, strong chemical dependence, and high treatment costs, and achieves complete removal of cyanide and chemical dependence. The effect of low performance and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

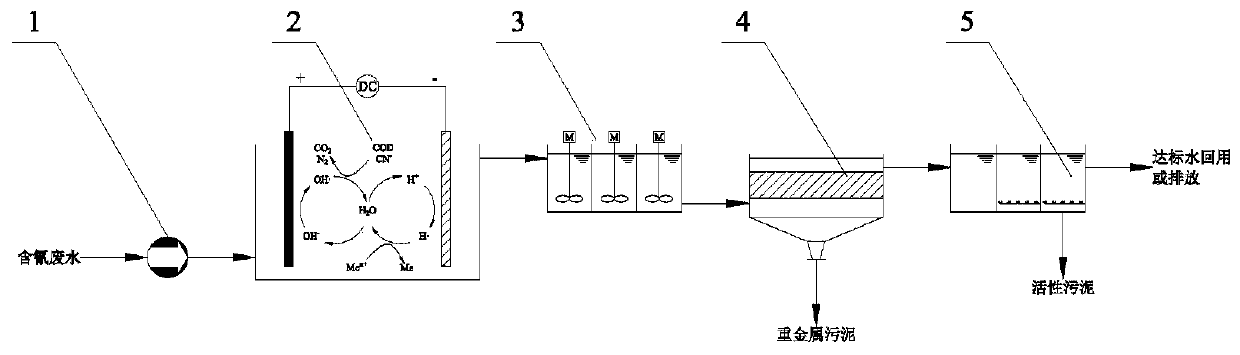

[0091] Such as figure 1 , 2 Shown, a kind of cyanogen-containing wastewater electrocatalytic oxidation treatment method, concrete steps are:

[0092] 1) Transporting cyanide-containing wastewater to the electrocatalytic oxidation reactor 2;

[0093] 2) In the electrocatalytic oxidation reactor 2, the cyanide-containing wastewater is electrocatalytically oxidized;

[0094] 3) enter in the coagulation reaction box 3, carry out neutralization reaction;

[0095] 4) enter in clarifier 4, clarify;

[0096] 5) Enter the biochemical treatment device 5 for biochemical treatment.

[0097] In order to further explain this embodiment, it should be noted that,

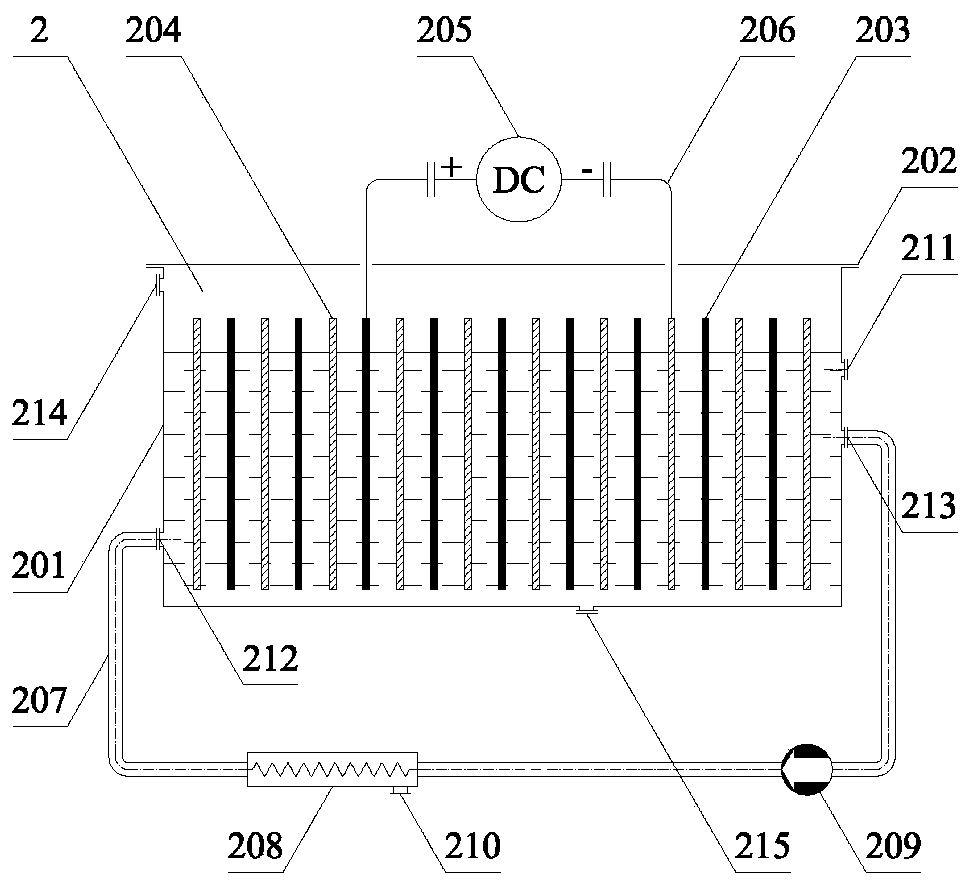

[0098] In step 1), the cyanide-containing waste water enters the pipeline mixer 208 from the water inlet 210, and after mixing with the circulating waste water in the circulating pipe 207, enters the reactor box 201 of the electrocatalytic oxidation reactor 2 from the circulating water inlet 212;

[0099] In step 2), the elec...

Embodiment 2

[0128] Such as figure 1 , 2 As shown, an electrocatalytic oxidation treatment system for cyanide-containing wastewater includes a delivery pump 1, an electrocatalytic oxidation reactor 2, a coagulation reaction box 3, a clarifier 4, and a biochemical treatment device 5;

[0129] The delivery pump 1 is connected to the electrocatalytic oxidation reactor 2, and is used to transport cyanide-containing wastewater;

[0130] The electrocatalytic oxidation reactor 2 is connected with the coagulation reaction box 3, and is used for electrocatalytic oxidation of cyanide-containing wastewater;

[0131] The coagulation reaction box 3 is connected with the clarifier 4, and is used to convert free heavy metals into sediments by inputting lime milk or liquid caustic soda, coagulant and coagulant aid;

[0132] The clarifier 4 is connected with the biochemical treatment device 5, and is used to obtain clear water through clarification;

[0133] The biochemical treatment device 5 is used to...

Embodiment 3

[0160] Such as figure 1 , 2 Shown, a kind of cyanide-containing wastewater electrocatalytic oxidation treatment method, cyanide-containing wastewater is cyanide copper plating process manual production line wastewater, CN group concentration 400mg / L, total copper 165mg / L, pH between 9 ~ 10, COD Around 1000mg / L, total nitrogen 250mg / L, total phosphorus 30mg / L, conductivity 5000μS / cm. The cyanide-containing wastewater is transported to the pipeline mixer 208 through the transport pump 1, mixed with the circulating water and then enters the electrocatalytic oxidation reactor 2 along the circulating water inlet 212, the circulating water inlet flow ratio is 8:1, and the control voltage is 6.5V~ The electrocatalytic oxidation reaction is carried out between 7.5V, the CN group concentration in the reactor is reduced to less than 0.2mg / L, and the waste water that has completed the "cyanide breaking" process flows out from the water outlet 211.

[0161] The waste water flowing out f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com