Glass ceramics whispering gallery mode resonant cavity capable of outputting single mode high-performance laser and preparation method thereof

A technology of whispering gallery mode and glass-ceramics, which is applied in the field of optical devices, can solve the problems that the microcavity cannot realize laser output, reduce the quality factor of the microcavity, increase the surface scattering loss, etc., achieve single-mode laser output, reduce the threshold, Effect of improving slope efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

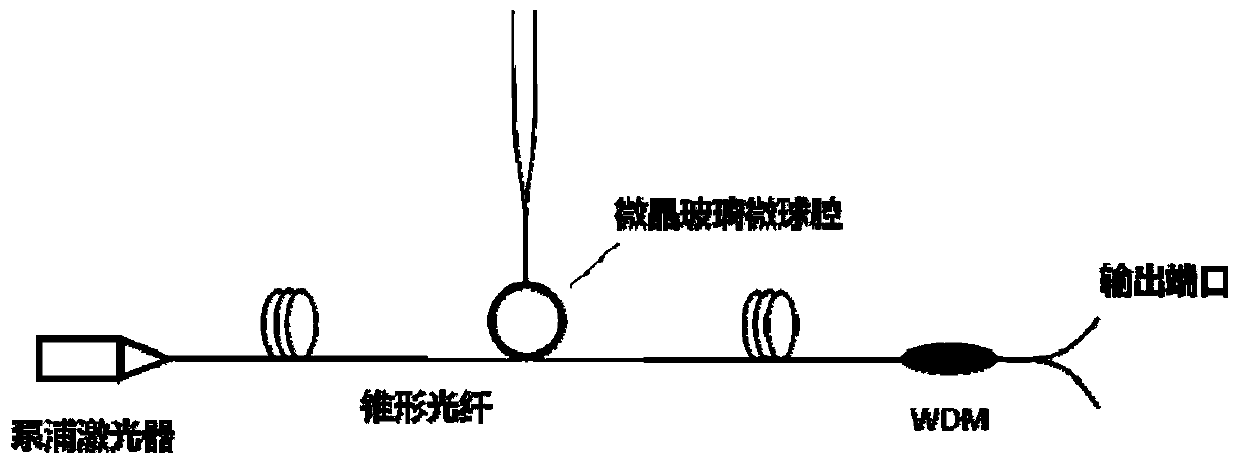

Method used

Image

Examples

Embodiment 1

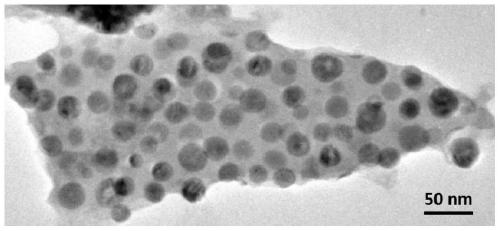

[0031] (1) Preparation of Er 3+ Mole percentage of each component of doped whispering gallery mode microcavity glass: SiO 2 :20%, B 2 o 3 :35%, Na 2 CO 3 :20%, ZnO:10%, YF 3 :10%, Er 3 :5%.

[0032] (2) Weigh 50g of raw materials according to the formula, and mix them well in an agate mortar.

[0033] (3) Pour the uniformly mixed material into a 100ml corundum crucible, and wait for the high temperature box-type resistance furnace to rise to 1000 o At C, put the corundum crucible filled with materials into the furnace for 1 hour, then take it out and put it into the furnace to preheat to 700 o In the refractory brick mold of C, and the quartz glass rod is used to pick the wire, the active glass fiber with a diameter of 10 μm to 500 μm can be obtained.

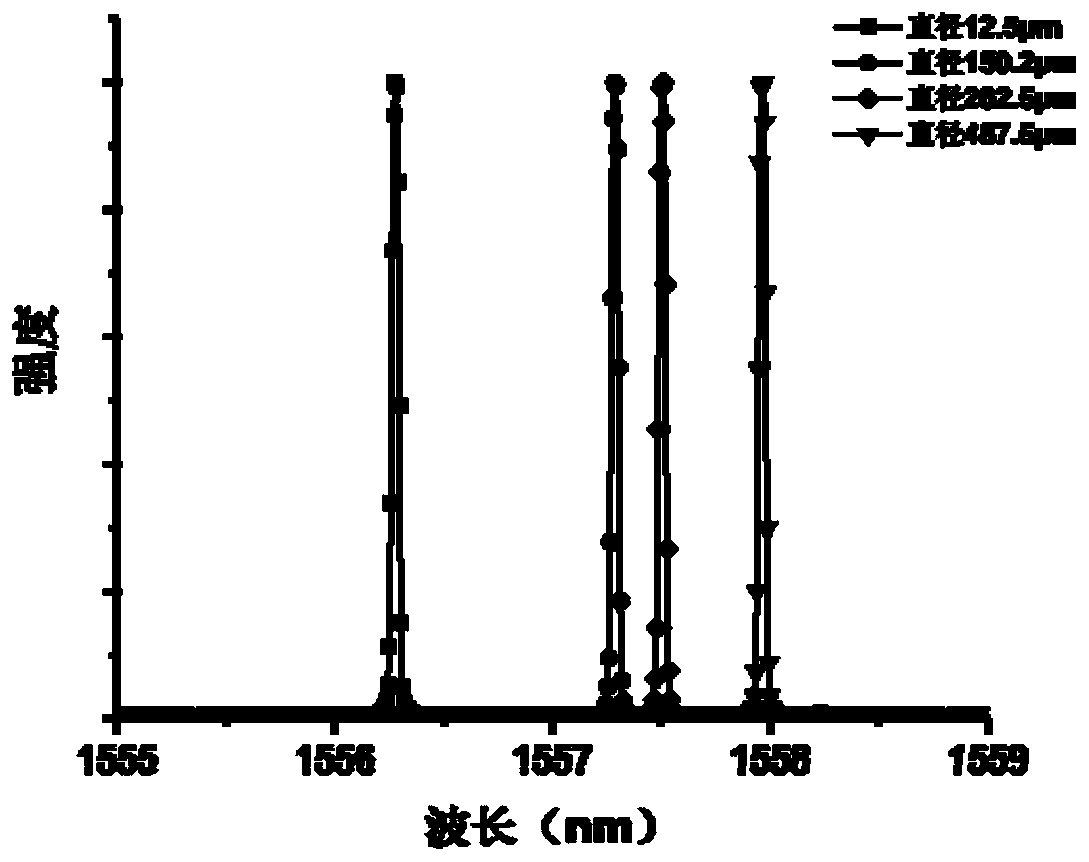

[0034] (4) Cut off a section of active glass fiber with a length of 5 cm and a diameter of about 200 μm, melt the middle part with a heating source such as a carbon dioxide laser or a hydrogen-oxygen flame, and clamp b...

Embodiment 2

[0041] (1) Preparation of Er 3+ Mole percentage of each component of doped whispering gallery mode microcavity glass: SiO 2 :20%, B 2 o 3 : 39.9%, Na 2 CO 3 :20%, ZnO:10%, YF 3 :10%, Er 3 :0.1%.

[0042] (2) Weigh 50g of raw materials according to the formula, and mix them well in an agate mortar.

[0043] (3) Pour the uniformly mixed material into a 100ml corundum crucible, and wait for the high temperature box-type resistance furnace to rise to 1000 o At C, put the corundum crucible filled with materials into the furnace for 1 hour, then take it out and put it into the furnace to preheat to 700 o In the refractory brick mold of C, and the quartz glass rod is used to pick the wire, the active glass fiber with a diameter of 10 μm to 500 μm can be obtained.

[0044] (4) Cut off a section of active glass fiber with a length of 5 cm and a diameter of about 200 μm, melt the middle part with a heating source such as a carbon dioxide laser or a hydrogen-oxygen flame, and cl...

Embodiment 3

[0050] Example 3 (1) Preparation of Er 3+ Mole percentage of each component of doped whispering gallery mode microcavity glass: SiO 2 :20%, B 2 o 3 :39%, Na 2 CO 3 :20%, ZnO:10%, YF 3 :10%, Er 3 :1%.

[0051] (2) Weigh 50g of raw materials according to the formula, and mix them well in an agate mortar.

[0052] (3) Pour the uniformly mixed material into a 100ml corundum crucible, and wait for the high temperature box-type resistance furnace to rise to 1000 o At C, put the corundum crucible filled with materials into the furnace for 1 hour, then take it out and put it into the furnace to preheat to 700 o In the refractory brick mold of C, and the quartz glass rod is used to pick the wire, the active glass fiber with a diameter of 10 μm to 500 μm can be obtained.

[0053] (4) Cut off a section of active glass fiber with a length of 5 cm and a diameter of 200 μm, melt the middle part with a heating source such as a carbon dioxide laser or a hydrogen-oxygen flame, and cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com