Visible light high absorbability far infrared high reflection film and preparation method thereof

A high-reflection film and high-absorption technology, applied in optics, optical components, sputtering coating, etc., can solve the problems of too bright surface, complex preparation process of low infrared emissivity coating, etc., and achieve reduced brightness and low reflectivity , the effect of high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

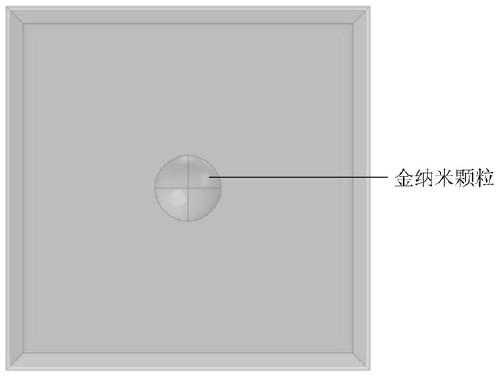

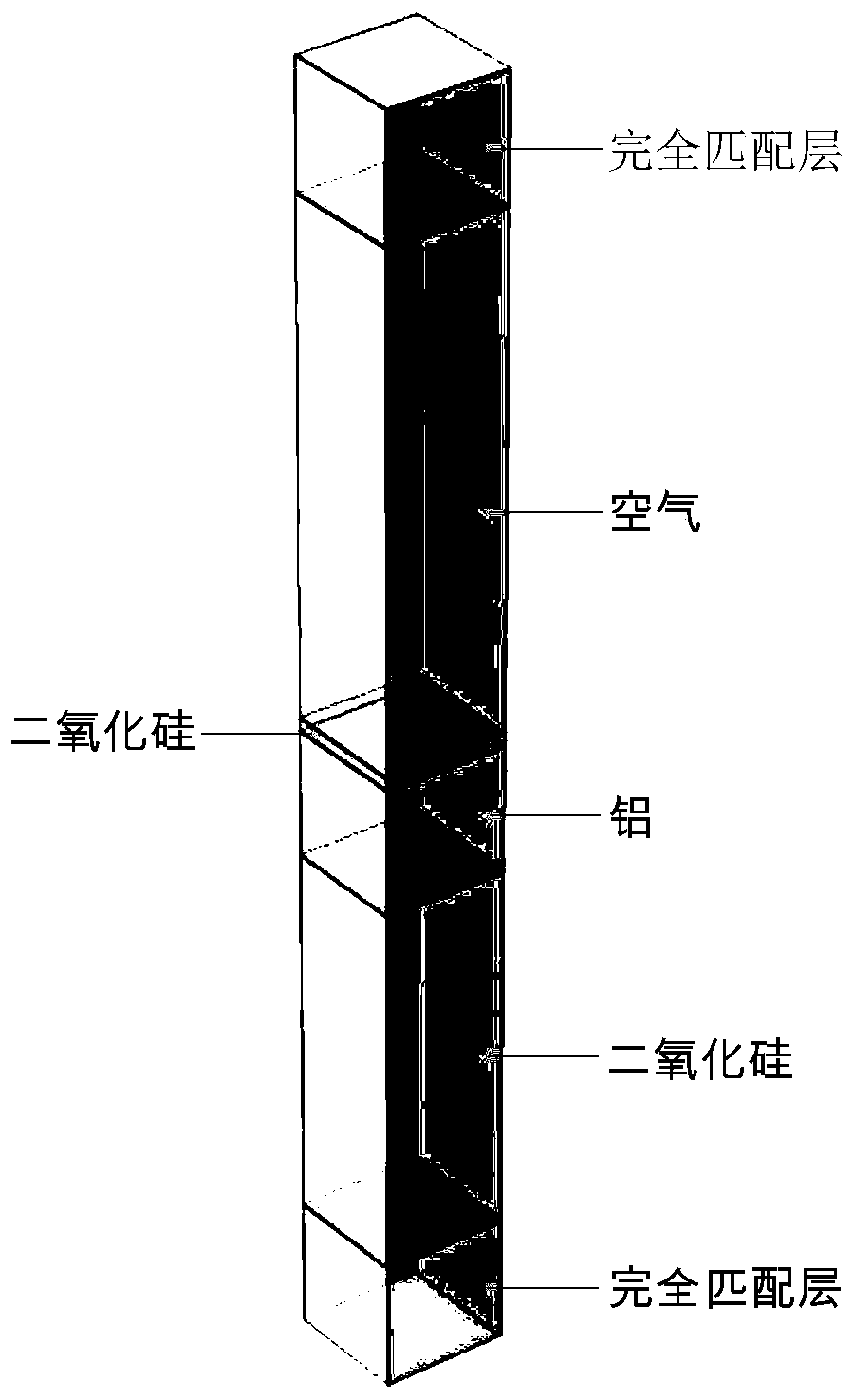

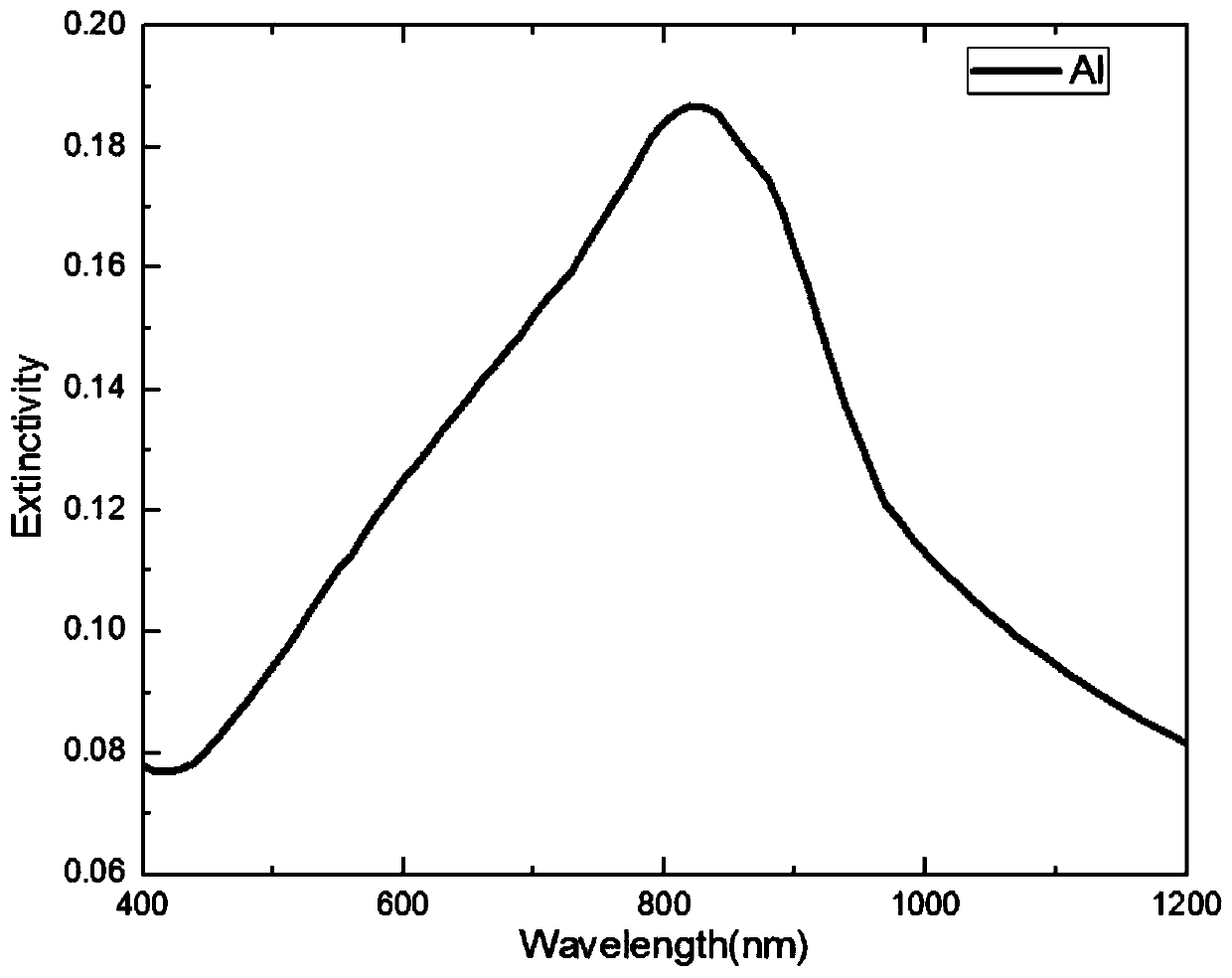

[0028] The schematic diagram of the simulation structure of the periodic unit of the present invention is as figure 2 shown; base layer is SiO 2 / Si substrate and aluminum film, where SiO 2 The thickness is 300nm, the thickness of the aluminum film is 50nm, the thickness of the dielectric layer is 5-9nm, the metal nano-island is a hemisphere with a radius of 5-25nm, the aluminum film and SiO 2 SiO on / Si substrate 2 contact on one side.

[0029] Its preparation method is:

[0030] Step 1. Electron beam evaporation on SiO 2 A layer of 50nm Al film was evaporated on the / Si substrate as the base layer.

[0031] Step 2, radio frequency sputtering a layer of SiO on the Al film with a magnetron sputtering device 2 film, the sputtering time is 5min, 7min, 9min respectively, the sputtering power is 80W, the corresponding SiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com