Environmental-protection aluminum alloy surface treatment liquid and preparation method thereof

A technology of aluminum alloy surface and treatment liquid, which is applied in the field of environment-friendly aluminum alloy surface treatment liquid and its preparation, can solve problems such as aluminum alloy surface corrosion and damage to aluminum alloy, and achieve durable cleaning power, low cost, and rapid and thorough cleaning speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

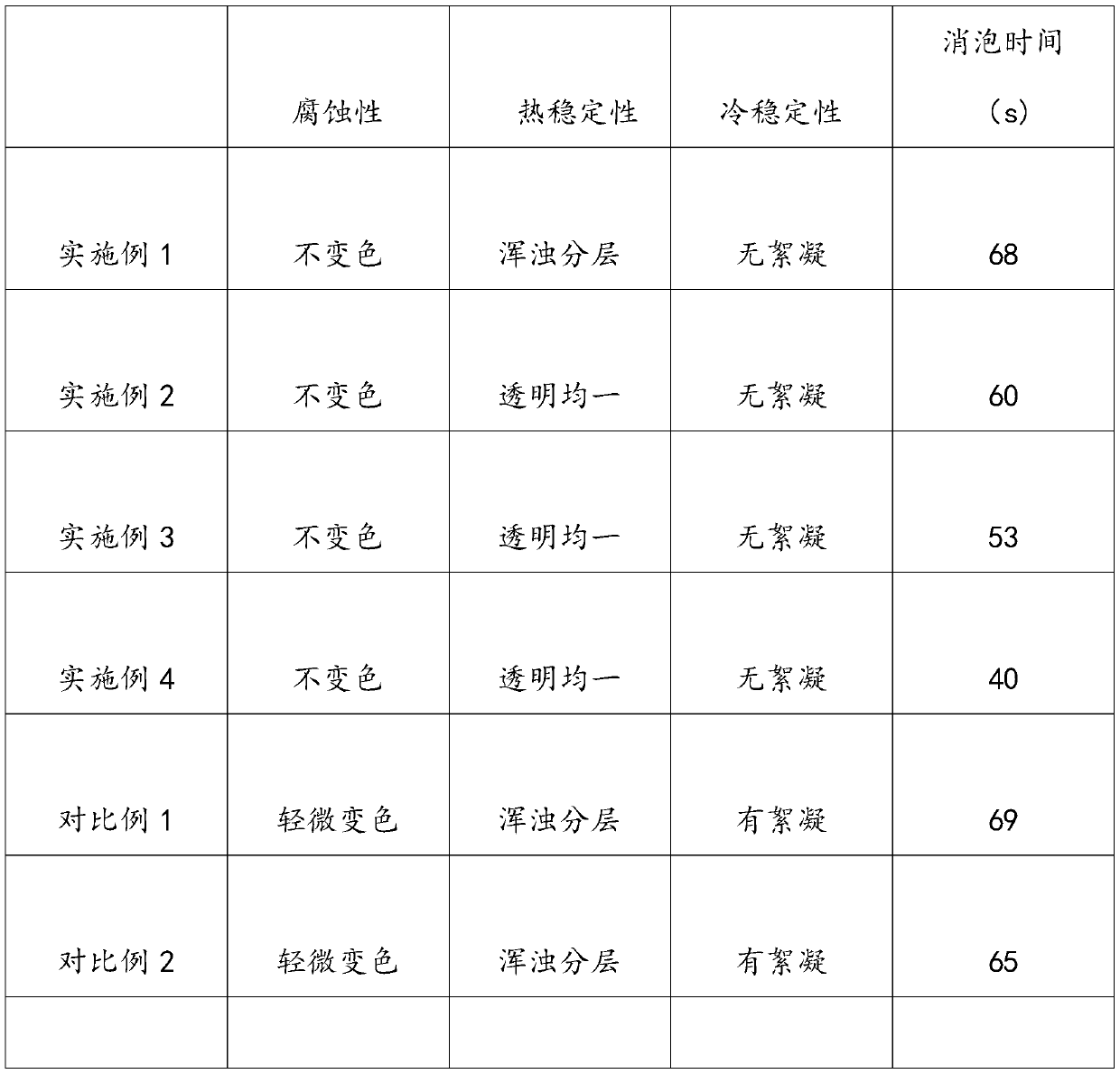

Embodiment 1

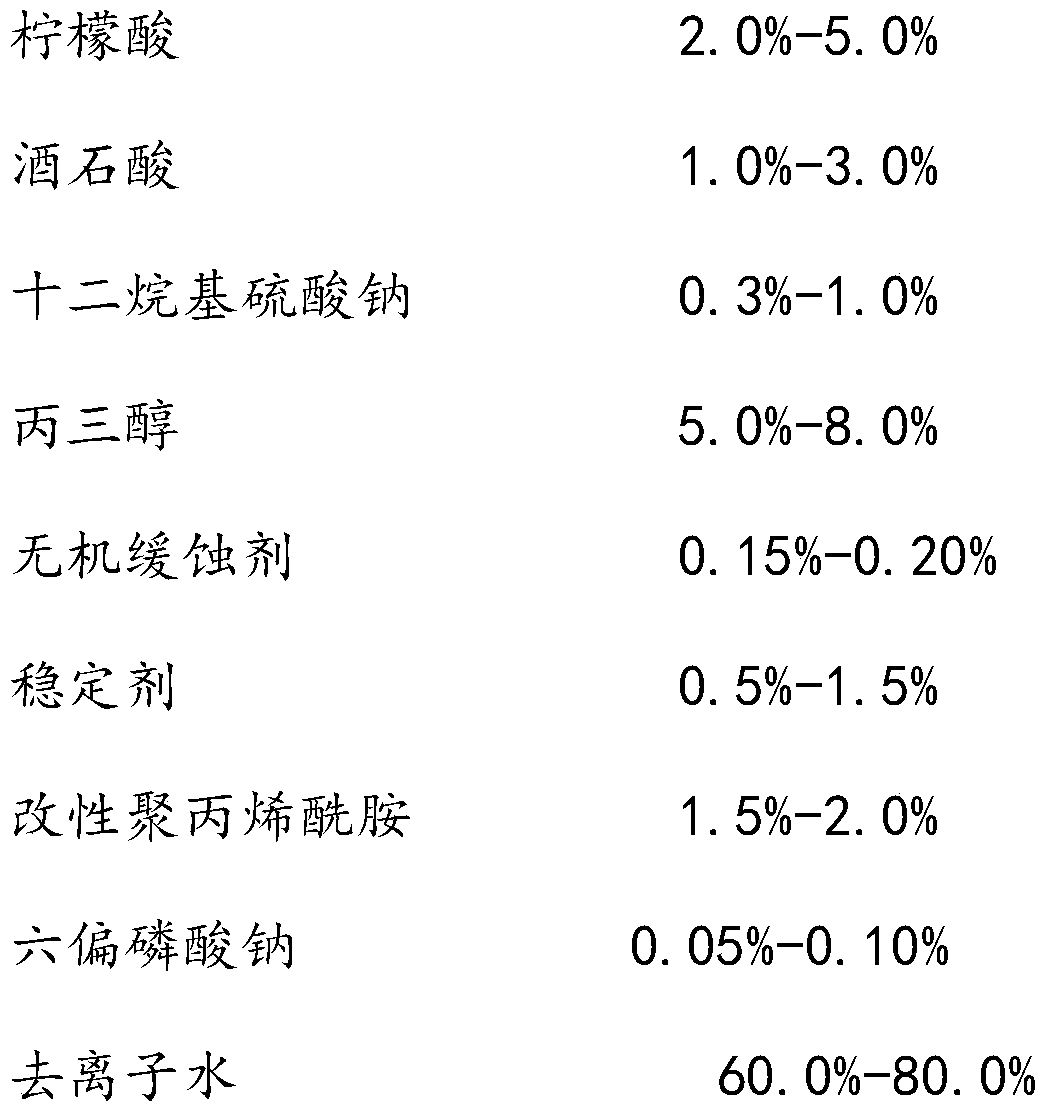

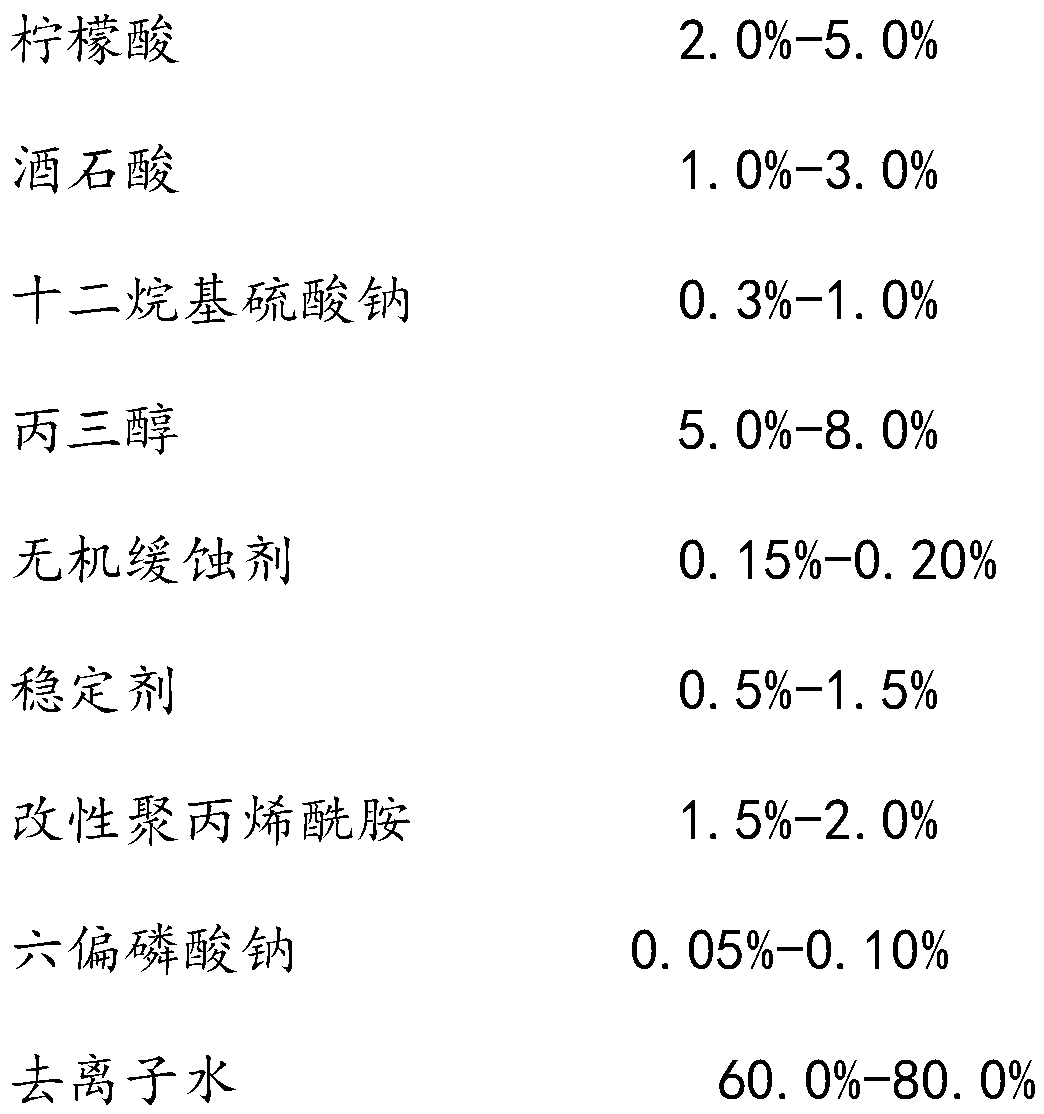

[0034] An environment-friendly aluminum alloy surface treatment liquid is made of the following raw materials in weight percentage: citric acid 2.0%, tartaric acid 1.0%, sodium lauryl sulfate 0.3%, glycerol 5.0%, sodium silicate 0.15%, stearin Potassium acid potassium 0.5%, modified polyacrylamide 1.5%, sodium hexametaphosphate 0.05%, deionized water 60.0%;

[0035] The environmental protection aluminum alloy surface treatment liquid is made by the following steps:

[0036] Step S1, add citric acid and tartaric acid into a three-neck flask filled with half of deionized water, heat in a water bath at 45°C, stir at a constant speed for 30 minutes, and then pass in nitrogen to exhaust the air to prepare a mixed solution A;

[0037] Step S2, put the modified polyacrylamide and sodium hexametaphosphate into a beaker, add the other half of deionized water until the modified polyacrylamide and sodium hexametaphosphate are completely dissolved, add 10% dilute hydrochloric acid to adju...

Embodiment 2

[0045] An environment-friendly aluminum alloy surface treatment solution is made of the following raw materials in weight percentage: 2.5% citric acid, 1.5% tartaric acid, 0.5% sodium lauryl sulfate, 6.0% glycerol, 0.18% sodium silicate, stearin Potassium acid potassium 0.8%, modified polyacrylamide 1.7%, sodium hexametaphosphate 0.06%, deionized water 65.0%;

[0046] The environmental protection aluminum alloy surface treatment liquid is made by the following steps:

[0047] Step S1, add citric acid and tartaric acid into a three-neck flask filled with half of deionized water, heat in a water bath at 45°C, stir at a constant speed for 30 minutes, and then pass in nitrogen to exhaust the air to prepare a mixed solution A;

[0048] Step S2, put the modified polyacrylamide and sodium hexametaphosphate into a beaker, add the other half of deionized water until the modified polyacrylamide and sodium hexametaphosphate are completely dissolved, add 10% dilute hydrochloric acid to ad...

Embodiment 3

[0052] An environment-friendly aluminum alloy surface treatment liquid is made of the following raw materials in weight percentage: citric acid 4.5%, tartaric acid 2.8%, sodium lauryl sulfate 0.8%, glycerol 7.0%, sodium silicate 0.2%, stearin Potassium acid potassium 1.3%, modified polyacrylamide 1.8%, sodium hexametaphosphate 0.08%, deionized water 75.0%;

[0053] The environmental protection aluminum alloy surface treatment liquid is made by the following steps:

[0054] Step S1, add citric acid and tartaric acid into a three-neck flask filled with half of deionized water, heat in a water bath at 45°C, stir at a constant speed for 30 minutes, and then pass in nitrogen to exhaust the air to prepare a mixed solution A;

[0055] Step S2, put the modified polyacrylamide and sodium hexametaphosphate into a beaker, add the other half of deionized water until the modified polyacrylamide and sodium hexametaphosphate are completely dissolved, add 10% dilute hydrochloric acid to adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com