Large-area flexible perovskite solar cell and printing preparation method

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of increased production cost, unfavorable industrialization, and cumbersome preparation process, and achieve improved space utilization, improved stability and quality, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

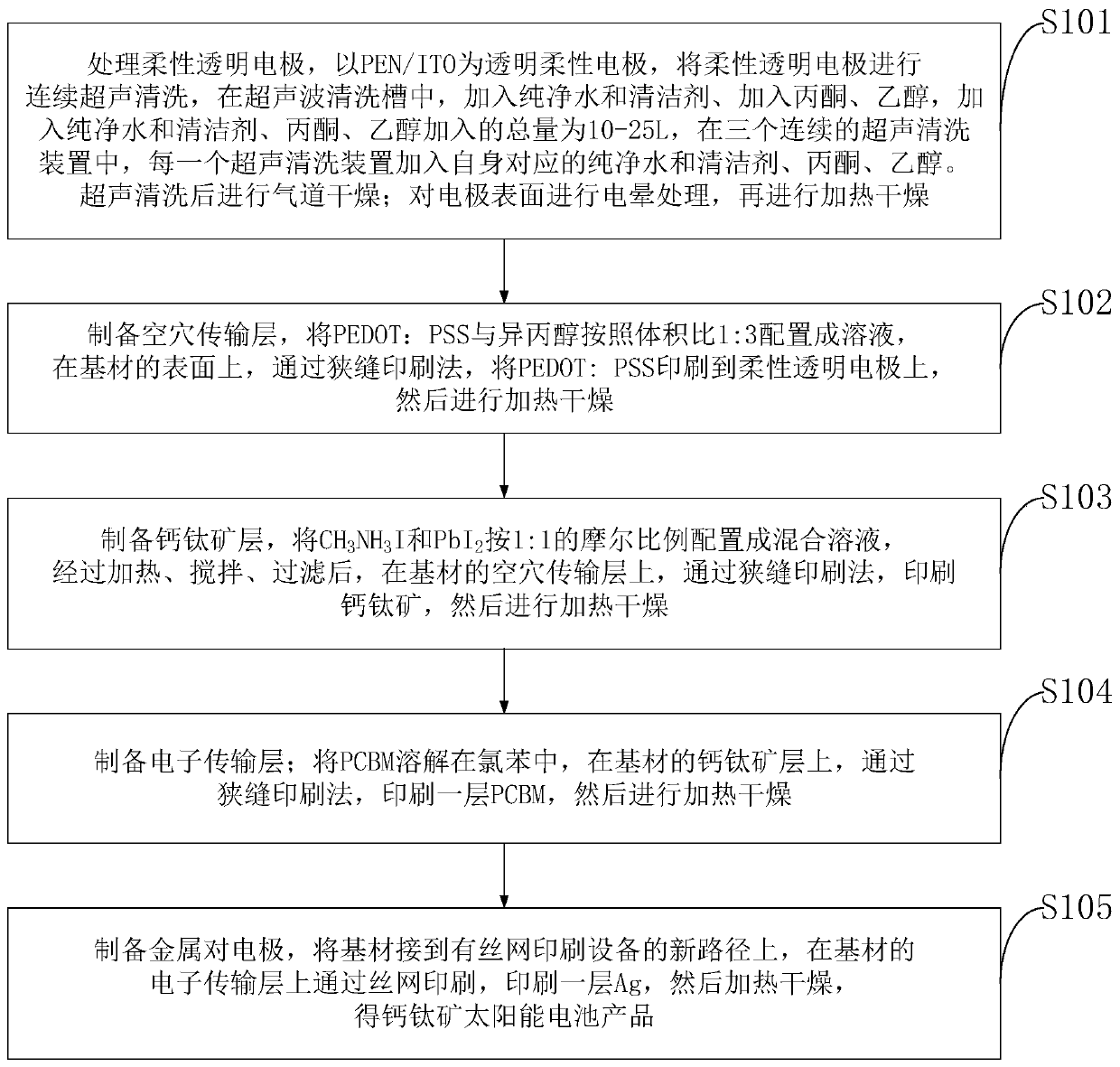

[0047] Such as figure 1 As shown, the large-area flexible perovskite solar cell printing preparation method provided by the embodiment of the present invention includes:

[0048] S101, process the flexible transparent electrode, use PEN / ITO as the transparent flexible electrode, conduct continuous ultrasonic cleaning on the flexible transparent electrode, add pure water and detergent, add acetone, ethanol, add pure water and detergent, The total amount of acetone and ethanol added is 10-25L. In three continuous ultrasonic cleaning devices, each ultrasonic cleaning device adds its own corresponding pure water and detergent, acetone and ethanol. After ultrasonic cleaning, the airway is dried; the surface of the electrode is treated with corona, and then heated and dried.

[0049] S102, prepare the hole transport layer, configure PEDOT:PSS and isopropanol into a solution according to the volume ratio of 1:3, and print PEDOT:PSS on the flexible transparent electrode on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com