A kind of modified biochar, biochar-based organic fertilizer and its preparation method and application

A technology of biochar and organic fertilizer, applied in the field of organic fertilizer, can solve the problems of declining soil quality of chemical fertilizers, low crop yield, environmental pollution, etc., and achieves the improvement of corn's ability to resist diseases and insect pests, good ventilation and water permeability, and increased water and fertilizer storage capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

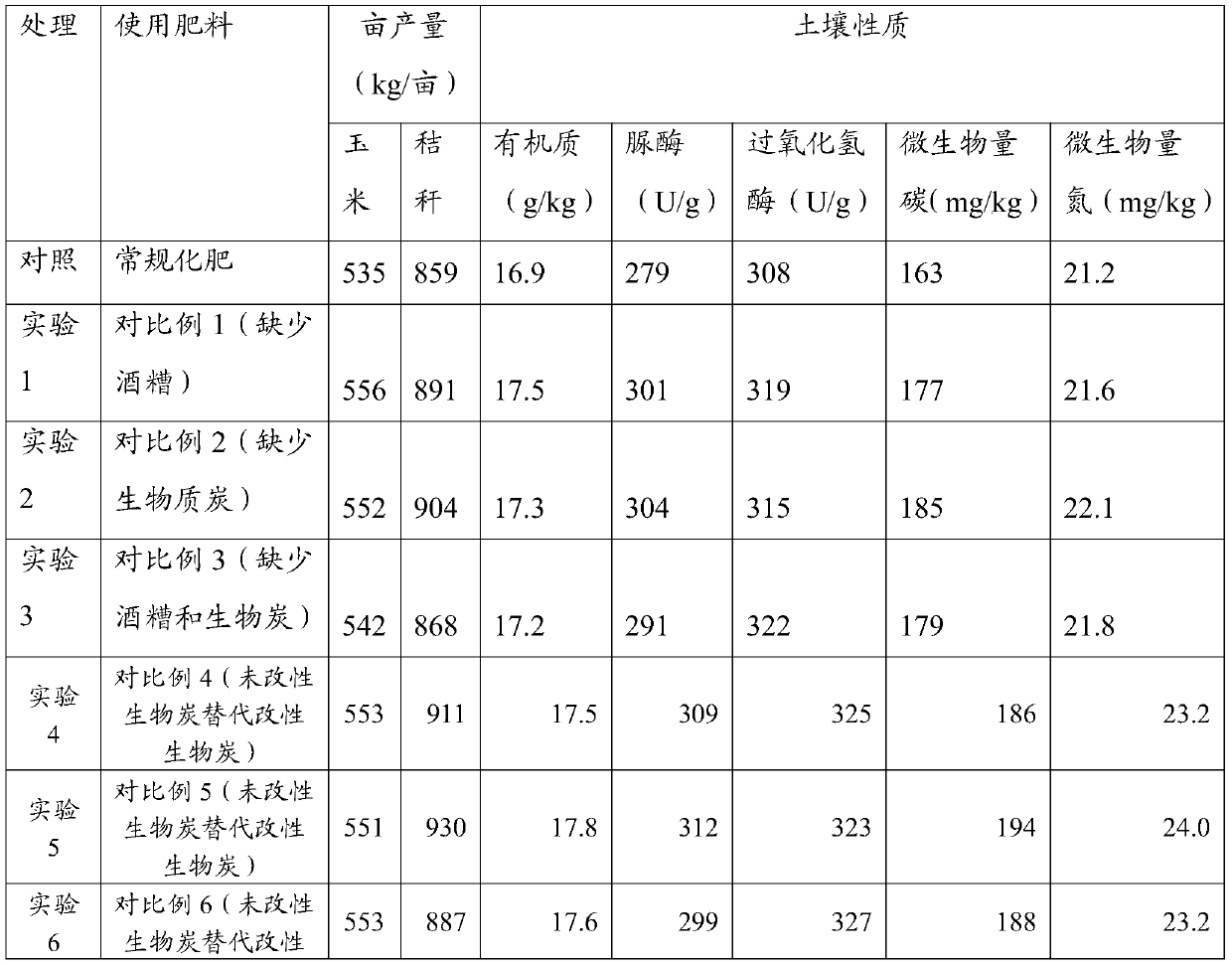

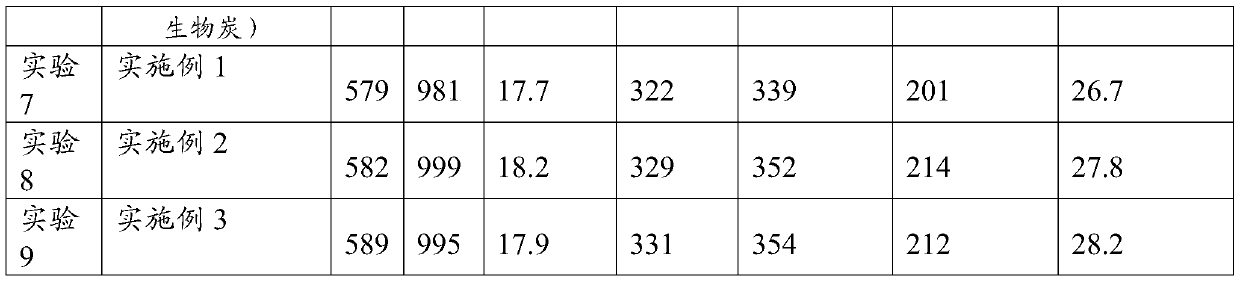

Examples

preparation example Construction

[0051] The raw material of the biochar-based organic fertilizer provided by the present invention includes Rhodotorula japonicus starter. In parts by weight, the rhodotorula japonicus starter is 3 to 5 parts, preferably 4 parts. The preservation number of the Rhodotorula gum OP11 is CGMCCNo.13540; the viable count of the Rhodotorula gum starter is preferably 3×10 8 ~1×10 9 CFU / g. The function of the rhodotorula japonicus starter is to accelerate the decomposing of the compost material, increase the temperature, control the odor, and increase the beneficial microorganisms in the finished compost. In the embodiment of the present invention, the preparation method of described Rhodotorula japonicus starter preferably comprises the following steps:

[0052] The original strain of strain OP11 was inoculated on wort solid medium under aseptic conditions, and cultured at 30°C for 2 days for activation; the activated strain was inoculated in wort liquid medium under aseptic conditi...

Embodiment 1

[0066] Preparation method of modified biochar

[0067] The peach wood biomass was washed 4 times with water to remove surface adherents, air-dried for 2 days, then dried overnight in an oven at 80°C, crushed, passed through a 100-mesh sieve, and collected under the sieve and packed in bottles for later use.

[0068] The carbonization equipment is a program-controlled muffle furnace.

[0069] Method: The peach wood residue powder and graphene oxide prepared above were mixed in a crucible according to the mass ratio of 100:1, and slowly heated in a muffle furnace at 600°C under the protection of a nitrogen atmosphere (atmosphere flow rate was controlled at 300mL / min). Pyrolysis for 2 hours, peach wood residue powder to produce biochar. Take 5.0g biochar with 50mL KMnO 4 (0.079M) solution, and then pyrolyzed at 600 °C for 0.5 h to produce crude modified biochar. The obtained crude modified biochar was thoroughly washed with deionized (DI) water to remove impurities. The washe...

Embodiment 2

[0072] A preparation method of modified biochar and distiller's grains fermented organic fertilizer, comprising the following steps:

[0073] Raw materials weighing the following weights: 30kg of modified biochar prepared in Example 1, 60kg of cow dung, 15kg of distiller's grains, 10kg of peanut shell powder, 6kg of wood vinegar, 4kg of sugar beet molasses, 4kg of Rhodotorula ferment, 4kg of compound cellulase 0.1kg (sourced from Aspergillus niger, enzyme activity ranges from 100,000 to 200,000 U / g).

[0074] Decomposition of distiller's grains: dehydrate and dry the distiller's grains until the water content is less than 10%, fully stir, and carry out natural fermentation for 12 days. The decomposed distiller's grains are naturally air-dried to normal temperature, dried, pulverized in a pulverizer, and passed through a 20-mesh sieve to obtain decomposed distiller's grains.

[0075] Primary fermentation: Weigh the modified biochar, cow dung, peanut shell powder, and decompose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com