Novel vanadium oxide anode material preparation through valency regulation and surface modification

A vanadium oxide and electrode material technology, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of non-capacitive performance and poor stability, achieve low cost, increase active sites, and shorten diffusion channels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

[0023] First, vanadium oxide is obtained by a hydrothermal method, that is, the following steps are performed:

[0024] (a) Will (NH 4 )VO 3 Dissolve in the mixed solution of deionized water and ethanol, stir until dissolved;

[0025] (b) Use concentrated acid (concentrated hydrochloric acid or concentrated nitric acid) to adjust the pH value to 1.5-3.5;

[0026] (c) solution is transferred in the reactor;

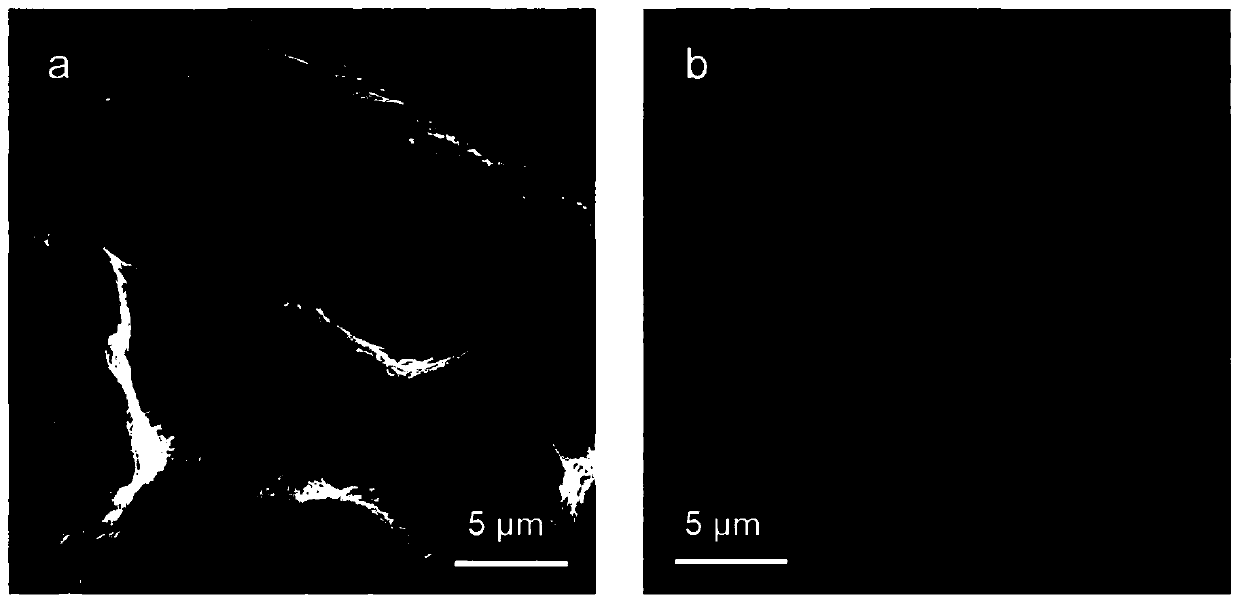

[0027] (d) Immerse the carbon cloth in the solution and seal it, place it in an oven, set the temperature at 140-180°C, react for 12 hours, and cool down naturally;

[0028] (e) Take out the vanadium oxide carbon cloth material obtained after the reaction, wash with ethanol and deionized water three times respectively, and air-dry.

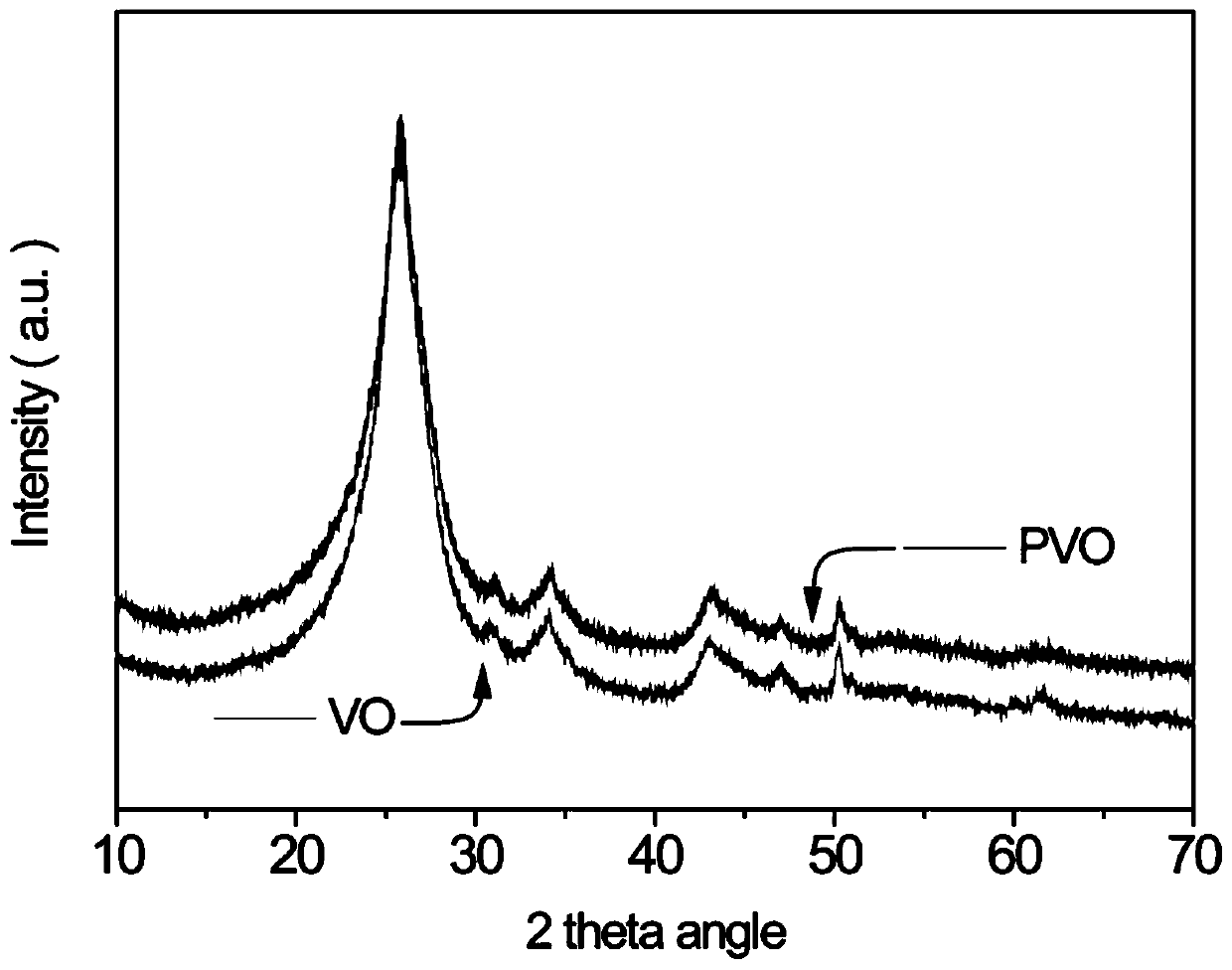

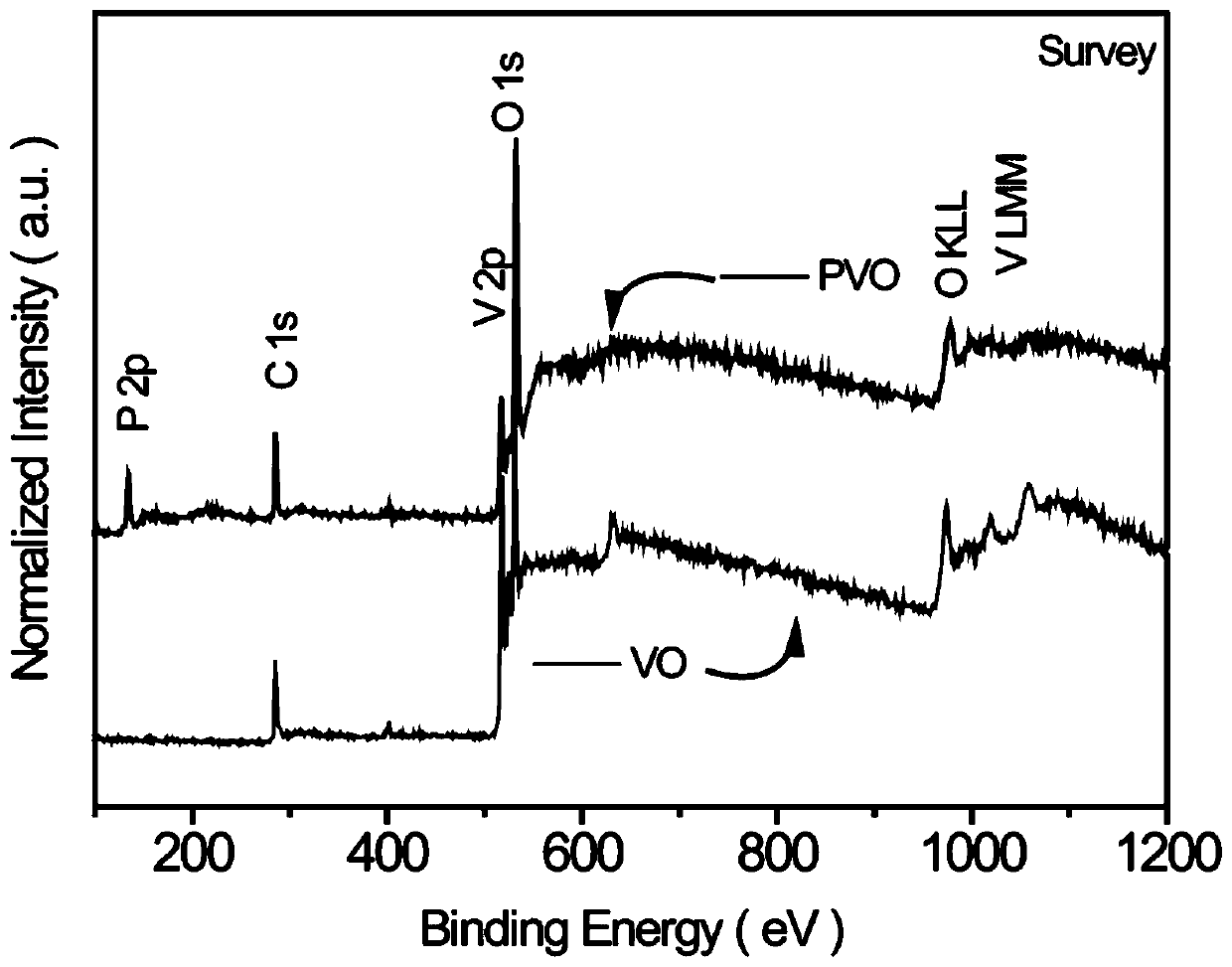

[0029] Then, the obtained vanadium oxide carbon cloth material is modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com