Method for improving compounding stability of potassium 2-hydroxy-4-methoxybenzoate and tranexamic acid

A technology of potassium methoxysalicylate and tranexamic acid, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of discoloration and poor stability of whitening products, and achieve the best use experience and long-term stability. , appearance and color stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

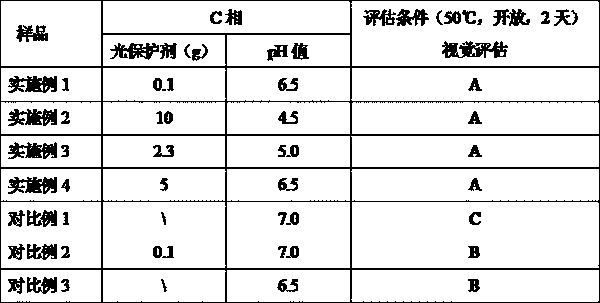

Examples

Embodiment 1

[0034] (1) Weigh the raw materials according to the following proportions for later use:

[0035] Phase A: 0.1g disodium EDTA, 0.2g xanthan gum, 1g glycerin, 2g butanediol, 1g plant extract composition and 80g water;

[0036] Phase B: PEG-100 stearate 1g, cetearyl alcohol 0.5g, glyceryl stearate 0.5g, C14-22 alcohol 1g, C12-20 alkyl glucoside 1g, squalane 1g, palmitic acid Ethylhexyl ester 2g and polydimethylsiloxane 3g;

[0037] Phase C: 0.04g sodium hydroxide, 0.1g preservative, 0.1g potassium methoxysalicylate, 0.1g tranexamic acid, 0.01g essence; 0.1g photoprotectant; 0.08g pH regulator; pH control of phase C at 6.5;

[0038] Among them, the photoprotectant components are: 0.01g of benzophenone-4, 0.01g of dibutyl adipate, 0.01g of diethylamine hydroxybenzoyl hexyl benzoate, 0.01g of ethylhexyl methoxycinnamate g, laureth-7 citrate 0.01g, polyglyceryl-2 dipolyhydroxystearate 0.01g, ethylhexyl triazone 0.01g, bis-ethylhexyloxyphenol methoxyphenyl triazone Oxyzine 0.01g,...

Embodiment 2

[0046] (1) Weigh the raw materials according to the following proportions for later use:

[0047]Phase A: 0.3g disodium EDTA, 1g xanthan gum, 5g glycerin, 4g butanediol, 8g plant extract composition and 60g water;

[0048] Phase B: PEG-100 stearate 3g, cetearyl alcohol 1.5g, glyceryl stearate 1g, C14-22 alcohol 5g, C12-20 alkyl glucoside 5g, squalane 5g, ethyl palmitate Hexyl ester 7g and polydimethylsiloxane 0.5g;

[0049] Phase C: 0.25g sodium hydroxide, 0.2g preservative, 1g potassium methoxysalicylate, 3g tranexamic acid, 0.2g essence; 10g photoprotectant; 15.12g pH regulator; the pH value of phase C is controlled at 4.5 ;

[0050] Among them, the photoprotectant components are: benzophenone-4 1g, dibutyl adipate 1g, diethylamino hydroxybenzoyl hexyl benzoate 1g, ethylhexyl methoxycinnamate 1g, lauryl alcohol Polyether-7 Citrate 1g, Polyglyceryl-2 Dipolyhydroxystearate 1g, Ethylhexyl Triazone 1g, Bis-Ethylhexyloxyphenol Methoxyphenyl Triazine 1g, Lauryl Glucoside 1g, 1...

Embodiment 3

[0058] (1) Weigh the raw materials according to the following proportions for later use:

[0059] Phase A: 0.2g disodium EDTA, 0.8g xanthan gum, 3g glycerin, 3g butanediol, 5g plant extract composition and 70g water;

[0060] Phase B: PEG-100 stearate 2g, cetearyl alcohol 1.0g, glyceryl stearate 0.8g, C14-22 alcohol 3g, C12-20 alkyl glucoside 3g, squalane 4g, palmitic acid Ethylhexyl ester 5g and polydimethylsiloxane 2.0g;

[0061] Phase C: 0.10g sodium hydroxide, 0.15g preservative, 0.15g potassium methoxysalicylate, 0.2g tranexamic acid, 0.1g essence; 2.3g photoprotectant; 10.065g pH regulator; pH value of phase C Control at 5.0;

[0062] Among them, the photoprotectant components are: benzophenone-4 0.05g, dibutyl adipate 0.05g, diethylamine hydroxybenzoyl hexyl benzoate 0.08g, ethylhexyl methoxycinnamate 0.02 g, Laureth-7 Citrate 0.03g, Polyglyceryl-2 Dipolyhydroxystearate 0.5g, Ethylhexyl Triazone 0.5g, Bis-Ethylhexyloxyphenol Methoxyphenyl Tris Oxyzine 0.75g, Lauryl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com