Tertiary air duct low-thermal-conductivity and high-wear-resistance brick and processing technology thereof

A processing technology and low thermal conductivity technology, applied in the field of refractory bricks, can solve the problems of brick body physical and chemical performance index damage, collapse, deep into the brick body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

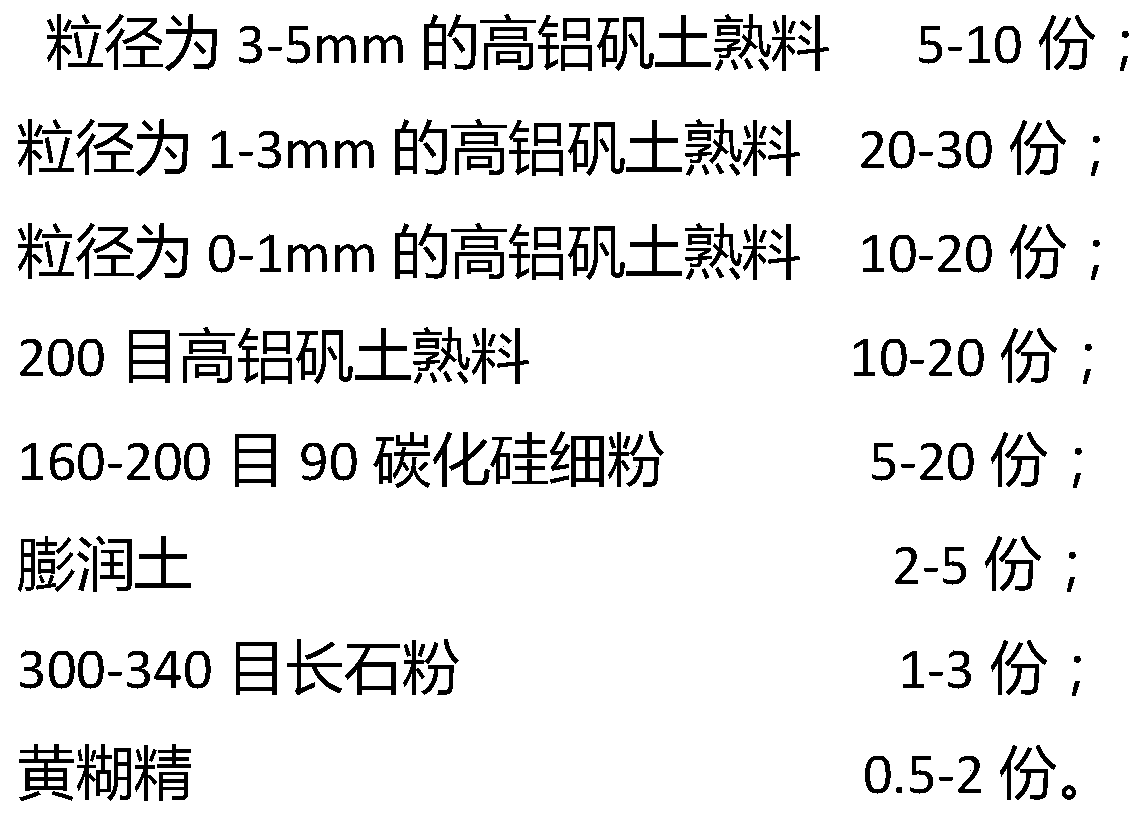

[0027] A tertiary air duct with low heat conduction and high wear resistance, comprising the following raw materials in parts by weight:

[0028]

[0029] Its processing technology includes the following steps:

[0030] 1) Mixing: Mix high-alumina bauxite clinker and yellow dextrin of different specifications, stir evenly, add appropriate amount of water, then add 90 silicon carbide fine powder, bentonite, feldspar powder, stir evenly, and form a billet;

[0031] 2) Molding: press molding with a 400-ton hydraulic press to make bricks;

[0032] 3) Drying: Send the shaped bricks into a tunnel drying kiln with an inlet temperature of 70°C and an outlet temperature of 110°C for drying, and leave the kiln to make dried bricks;

[0033] 4) Firing: Put the dried bricks into a high-temperature tunnel kiln for firing at a firing temperature of 1430°C, firing for 50 minutes, and then leave the kiln to obtain low thermal conductivity and high wear-resistant bricks;

[0034] 5) Cooli...

Embodiment 2

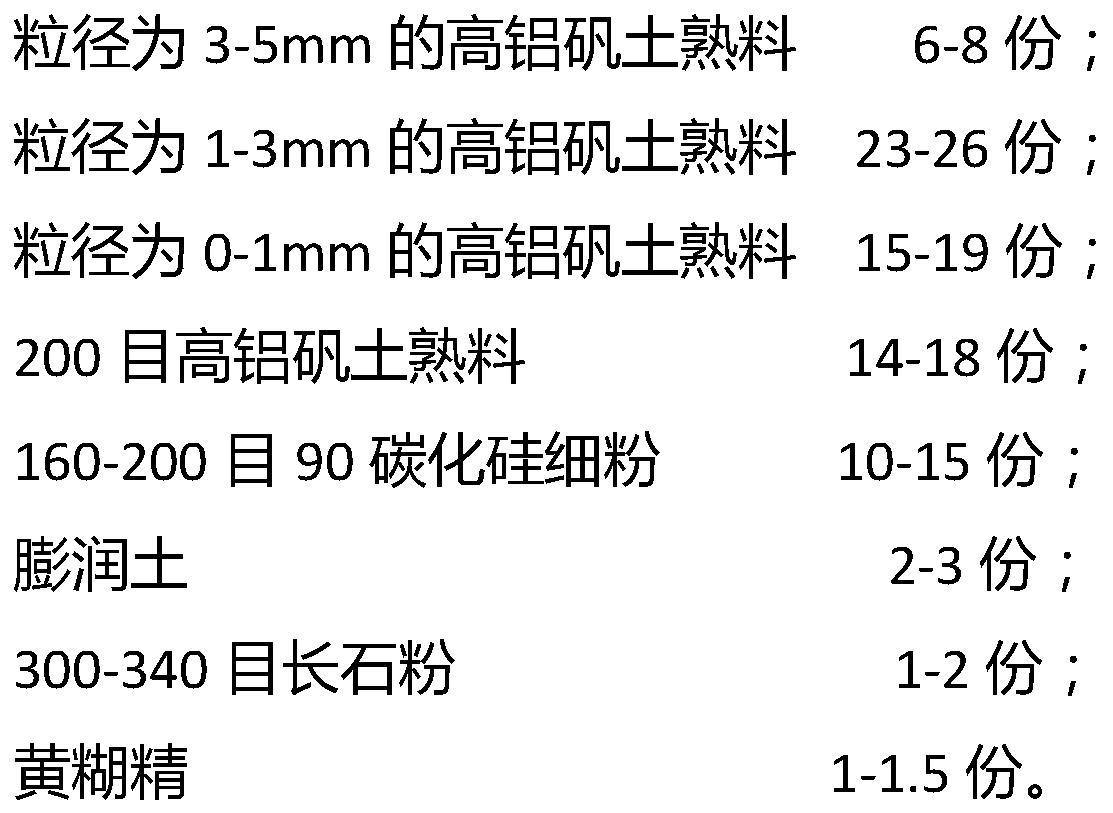

[0036] A tertiary air duct with low heat conduction and high wear resistance, comprising the following raw materials in parts by weight:

[0037]

[0038] Its processing technology includes the following steps:

[0039] 1) Mixing: Mix high-alumina bauxite clinker and yellow dextrin of different specifications, stir evenly, add appropriate amount of water, then add 90 silicon carbide fine powder, bentonite, feldspar powder, stir evenly, and form a billet;

[0040] 2) Molding: press molding with a 630-ton hydraulic press to make bricks;

[0041] 3) Drying: Send the shaped bricks into a tunnel drying kiln with an inlet temperature of 80°C and an outlet temperature of 120°C for drying, and then leave the kiln to make dried bricks;

[0042] 4) Firing: Put the dried bricks into a high-temperature tunnel kiln for firing at a firing temperature of 1470°C for 40 minutes, and then leave the kiln to obtain low thermal conductivity and high wear-resistant bricks;

[0043] 5) Cooling:...

Embodiment 3

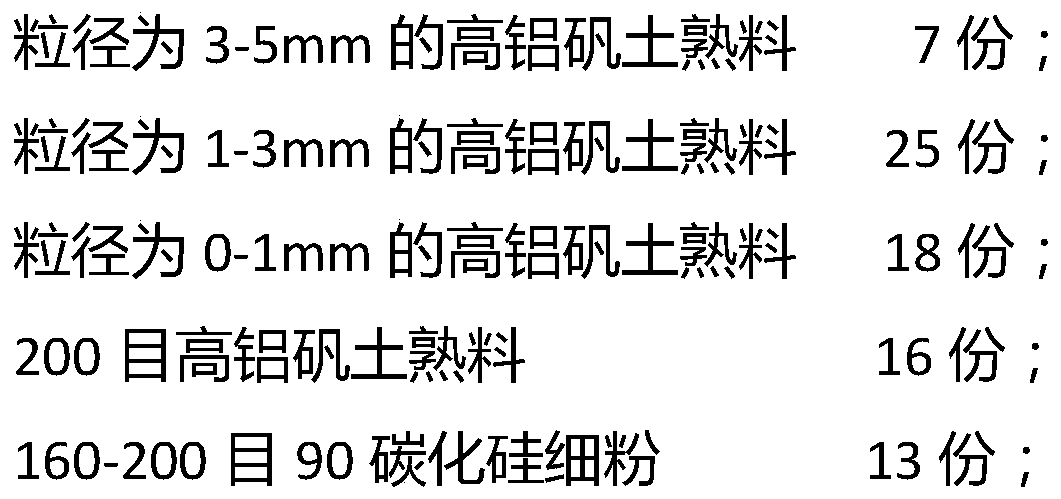

[0045] A tertiary air duct with low heat conduction and high wear resistance, comprising the following raw materials in parts by weight:

[0046]

[0047]

[0048] Its processing technology includes the following steps:

[0049] 1) Mixing: Mix high-alumina bauxite clinker and yellow dextrin of different specifications, stir evenly, add appropriate amount of water, then add 90 silicon carbide fine powder, bentonite, feldspar powder, stir evenly, and form a billet;

[0050] 2) Molding: press molding with a 630-ton hydraulic press to make bricks;

[0051] 3) Drying: Send the shaped bricks into a tunnel drying kiln with an inlet temperature of 90°C and an outlet temperature of 130°C for drying, and then leave the kiln to make dried bricks;

[0052] 4) Firing: Put the dried bricks into a high-temperature tunnel kiln for firing at a firing temperature of 1450°C for 45 minutes, and then leave the kiln to obtain low thermal conductivity and high wear-resistant bricks;

[0053]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Load softening temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com