Lithium ion battery electrode piece, preparation method thereof, and lithium ion battery

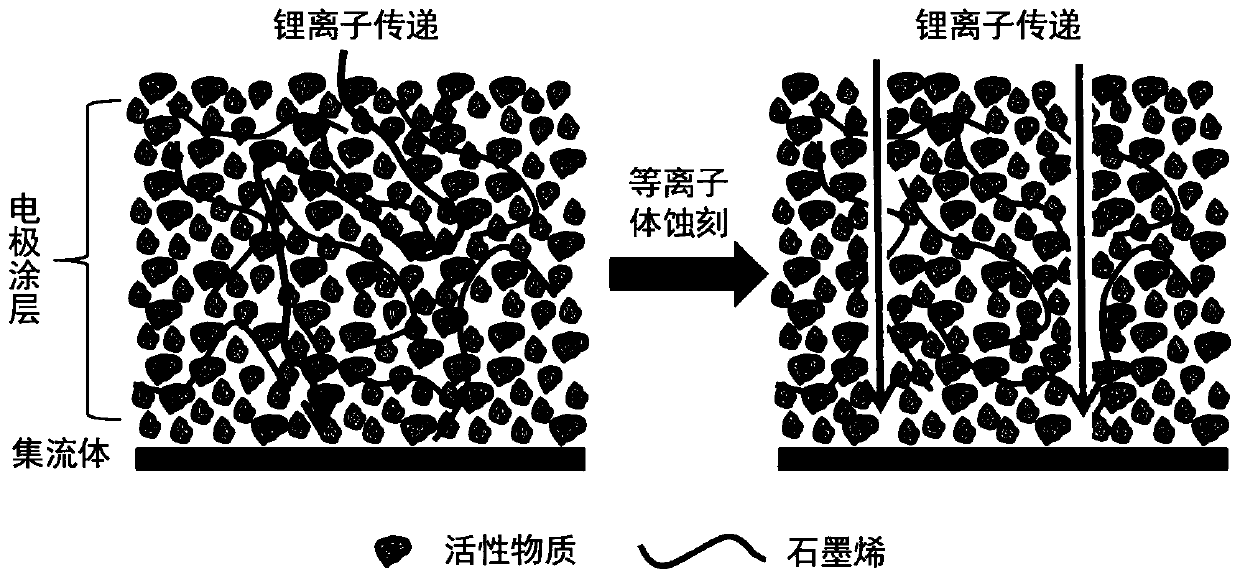

A lithium-ion battery and pole piece technology, applied in the field of lithium-ion battery pole piece and its preparation, can solve the problems of increasing the difficulty of lithium ion transmission, tortuous lithium ion conduction path, and poor battery power performance, so as to enhance ion conductivity , Facilitate transmission and reduce the effect of steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

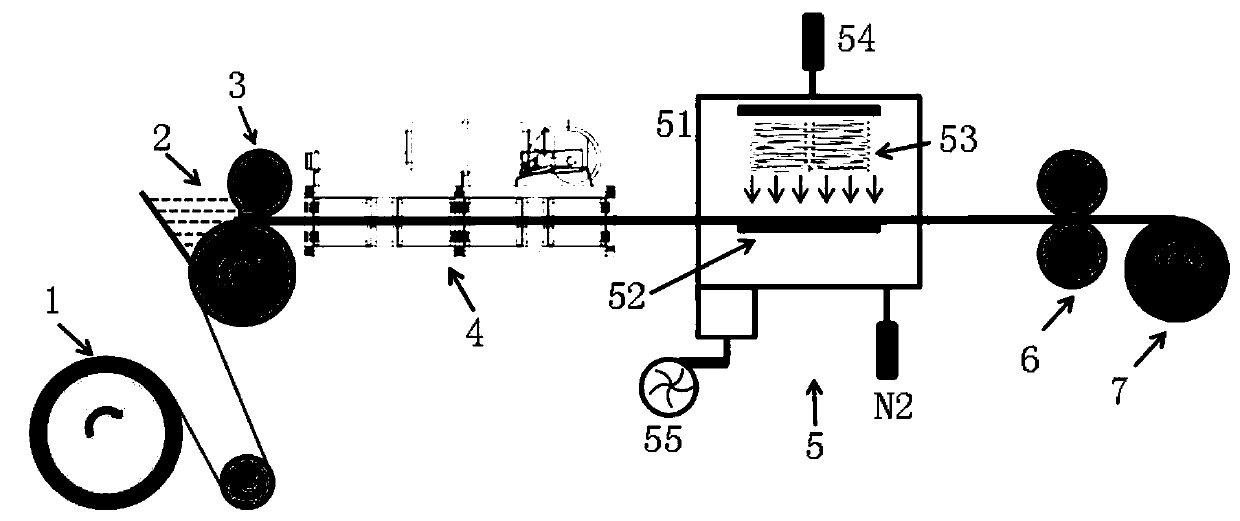

[0036] Embodiments of the present invention provide a method for preparing lithium-ion battery pole pieces on the one hand, figure 1 It is a schematic flow chart of the preparation method, comprising the following steps:

[0037] (1) Prepare slurry 2: mix electrochemically active material, graphene or graphene and carbon black, dispersant, binder and solvent, and stir to form slurry 2;

[0038] (2) Slurry coating: coating the prepared slurry 2 on the current collector 1 and drying the coating to obtain a dried pole piece;

[0039] (3) Plasma etching: use plasma etching equipment 5 to etch the dried pole piece at room temperature, and the plasma etching equipment includes a gas supply system 54, an etching chamber 51 and a vacuum system 55; Etching includes the following steps:

[0040] Transfer the pole piece into the etching chamber 51 and contact the lower electrode 52 in the etching chamber 51, seal the etching chamber 51 and evacuate it;

[0041] The gas supply system 5...

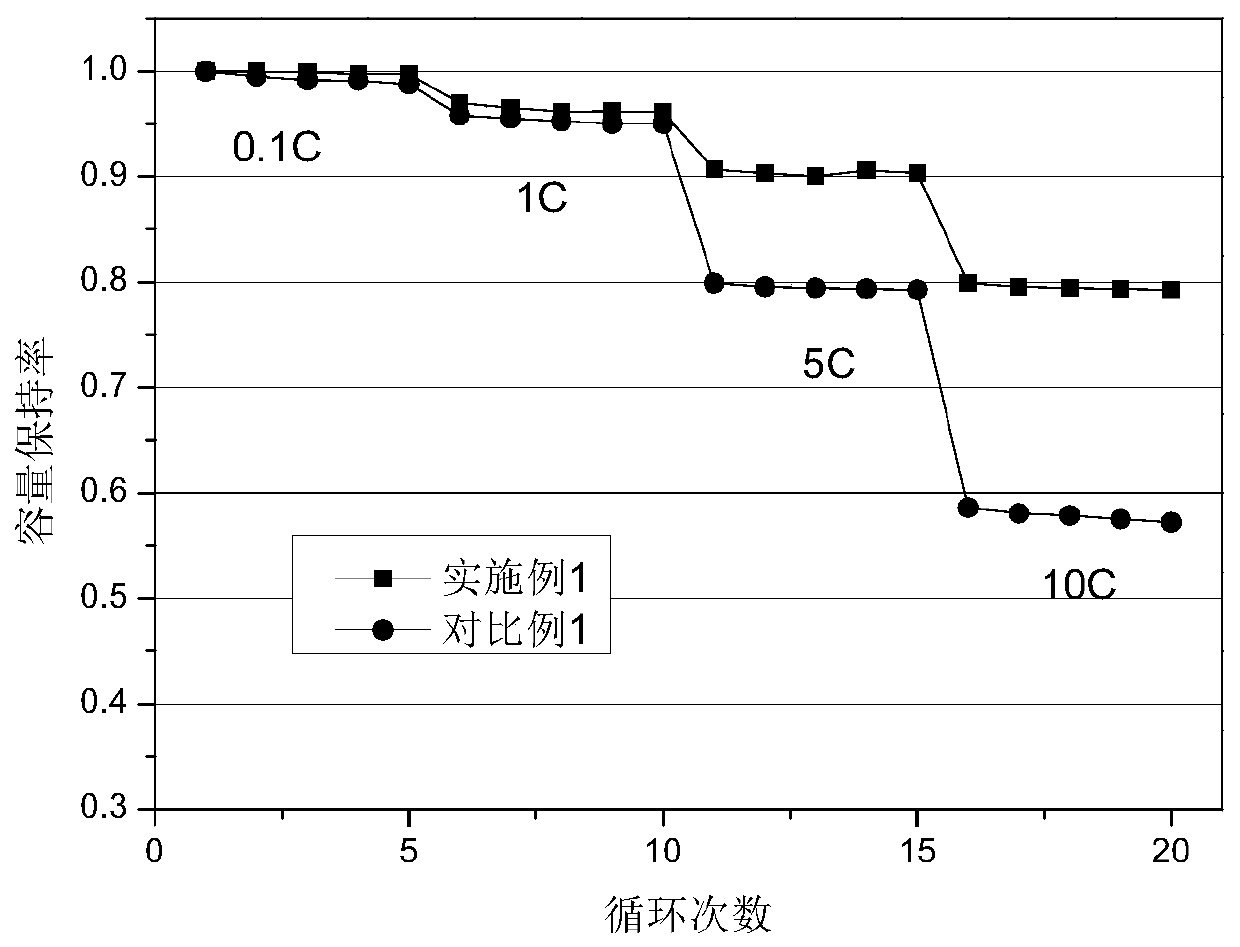

Embodiment 1

[0066] (1) Preparation of slurry: Add 0.5g of PVP to 10g of NMP, stir until PVP is fully dissolved, then add 1g of graphene, stir evenly to obtain a graphene dispersion; add 2g of PVDF to 40g of NMP, at 100rmp Stir at a low speed for 30 minutes until the PVDP is fully dissolved, add half of the graphene dispersion to it, stir at a speed of 100rmp for 10 minutes, then slowly add 46.5g of lithium iron phosphate while stirring, continue stirring at a low speed for 30 minutes after all the lithium iron phosphate is added, and then Add the remaining other half of the graphene dispersion, and stir at a high speed of 2000rmp for 2h; after fully dispersing, vacuumize the system and stir at a low speed of 100rmp for 30min to eliminate the air bubbles in the slurry; take out the slurry, and measure the viscosity to be about 6000cP. Sieve and set aside.

[0067] (2) Slurry coating: Transfer the prepared slurry to an automatic coating machine, select a 20 μm thick aluminum foil as a curre...

Embodiment 2

[0072] (1) Preparation of slurry: add 1g of PVP to 10g of NMP, stir until the PVP is fully dissolved, then add 2g of graphene, stir evenly to obtain a graphene dispersion; add 2g of PVDF into 40g of NMP, at a low speed of 100rmp Stir for 30 minutes until the PVDP is fully dissolved, add half of the graphene dispersion to it, stir at 100rmp for 10 minutes, then slowly add 50g of lithium iron phosphate while stirring, continue stirring at a low speed for 30 minutes after all the lithium iron phosphate is added, and then add the remaining The other half of the graphene dispersion was stirred at a high speed of 2000rmp for 2h; after fully dispersed, the system was vacuumed and stirred at a low speed of 100rmp for 30min to eliminate the air bubbles in the slurry; the slurry was taken out and the viscosity was measured to be 7000cP, and sieved for later use .

[0073] (2) Slurry coating: Transfer the prepared slurry to an automatic coating machine, select a 20 μm thick aluminum foil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com