Multilayer compound geomembrane used for soil remediation and production method thereof

A multi-layer composite and soil remediation technology, applied in the field of soil remediation, can solve problems such as poor corrosion resistance and weather resistance, soil secondary pollution, poor performance stability, etc., to achieve improved oxidation resistance, easy access to raw materials, and equipment less dependent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

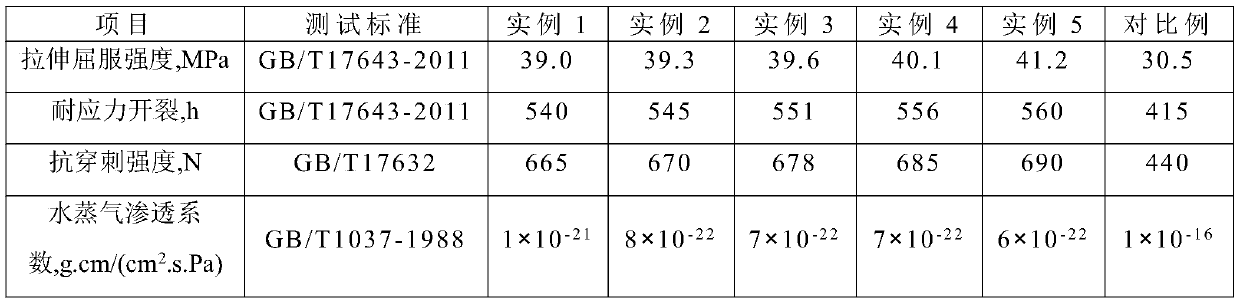

Examples

Embodiment 1

[0031] A multilayer composite geomembrane for soil restoration comprises a weather-resistant layer, a composite anti-corrosion and anti-seepage layer, and a weather-resistant layer in sequence from top to bottom; the weather-resistant layer and the composite anti-corrosion and anti-seepage layer are all bonded by an adhesive layer.

[0032] Wherein, the weather-resistant layer is made of polytetrafluoroethylene.

[0033] The composite anti-corrosion and anti-seepage layer is composed of glycidyl methacrylate grafted high-density polyethylene and 2,2-bis(3-amino-4-hydroxyphenyl)-hexafluoropropane and thiazolidine-2,4 -The polycondensate formed by polycondensation of dicarboxylic acid is blended and grafted, and then doped with surface-modified flake graphite.

[0034] The adhesive layer is composed of 30 parts of epoxy resin, 5 parts of 2,2-bis(4-isocyanatophenyl)hexafluoropropane, 50 parts of acrylic pressure-sensitive adhesive, 5 parts of nano-ceramic soil, and 60 parts of et...

Embodiment 2

[0041] A multilayer composite geomembrane for soil restoration comprises a weather-resistant layer, a composite anti-corrosion and anti-seepage layer, and a weather-resistant layer in sequence from top to bottom; the weather-resistant layer and the composite anti-corrosion and anti-seepage layer are all bonded by an adhesive layer.

[0042] The weather-resistant layer is made of polyvinylidene fluoride.

[0043] The composite anti-corrosion and anti-seepage layer is composed of glycidyl methacrylate grafted high-density polyethylene and 2,2-bis(3-amino-4-hydroxyphenyl)-hexafluoropropane and thiazolidine-2,4 -The polycondensate formed by polycondensation of dicarboxylic acid is blended and grafted, and then doped with surface-modified flake graphite.

[0044] The adhesive layer is composed of 33 parts of epoxy resin, 6.5 parts of 2,2-bis(4-isocyanatophenyl)hexafluoropropane, 55 parts of acrylic pressure-sensitive adhesive, 7 parts of nano-ceramic soil, and 65 parts of ethanol. ...

Embodiment 3

[0051] A multilayer composite geomembrane for soil restoration comprises a weather-resistant layer, a composite anti-corrosion and anti-seepage layer, and a weather-resistant layer in sequence from top to bottom; the weather-resistant layer and the composite anti-corrosion and anti-seepage layer are all bonded by an adhesive layer.

[0052] Wherein, the weather-resistant layer is made of polytetrafluoroethylene.

[0053] The composite anti-corrosion and anti-seepage layer is composed of glycidyl methacrylate grafted high-density polyethylene and 2,2-bis(3-amino-4-hydroxyphenyl)-hexafluoropropane and thiazolidine-2,4 -The polycondensate formed by polycondensation of dicarboxylic acid is blended and grafted, and then doped with surface-modified flake graphite.

[0054] The adhesive layer is composed of 35 parts of epoxy resin, 7 parts of 2,2-bis(4-isocyanatophenyl)hexafluoropropane, 60 parts of acrylic pressure-sensitive adhesive, 8 parts of nano-ceramic soil, and 70 parts of et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com