Medical porous fiber membrane and preparation method thereof

A porous fiber and mixture technology, applied in the field of biomedical materials, can solve the problems of insufficient mechanical strength, cumbersome manufacturing process, and poor biocompatibility, and achieve the effect of promoting wound healing, short process flow, and good pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

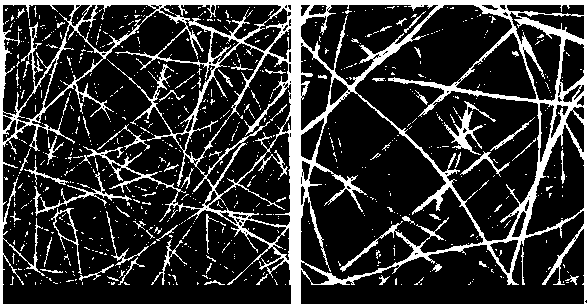

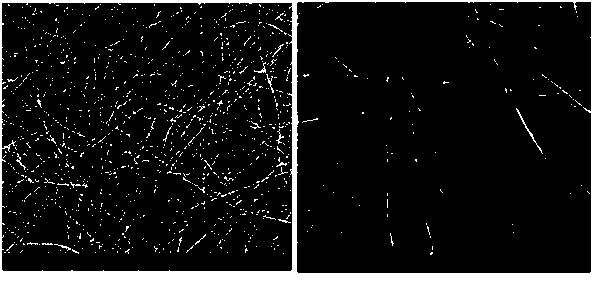

Image

Examples

Embodiment 1

[0028] A medical porous fiber membrane is prepared by electrospinning with sodium hyaluronate, gelatin, konjac glucomannan and nano-hydroxyapatite as raw materials.

[0029] The preparation method of the medical porous fiber membrane in this embodiment, the specific steps are as follows:

[0030] (1) Under the condition of magnetic stirring, according to the solid-liquid ratio g:mL of gelatin and glacial acetic acid is 1:2, mix gelatin and glacial acetic acid until the gelatin is completely dissolved and no air bubbles can be observed in the liquid to obtain For mixture A, the magnetic stirring speed is 400r / min;

[0031] (2) Under the condition of magnetic stirring, according to the solid-liquid ratio g:mL of konjac glucomannan and mixture A is 1:200, add konjac glucomannan to mixture A in step (1) to obtain mixture B , the magnetic stirring speed is 400r / min;

[0032] (3) Under the condition of magnetic stirring, according to the solid-liquid ratio g:mL of sodium hyalurona...

Embodiment 2

[0040] A medical porous fiber membrane is prepared by electrospinning with sodium hyaluronate, gelatin, konjac glucomannan and nano-hydroxyapatite as raw materials.

[0041] The preparation method of the medical porous fiber membrane in this embodiment, the specific steps are as follows:

[0042] (1) Under the condition of magnetic stirring, according to the solid-liquid ratio g:mL of gelatin and glacial acetic acid is 1:20, mix gelatin and glacial acetic acid until the gelatin is completely dissolved and no air bubbles can be observed in the liquid to obtain For mixture A, the magnetic stirring speed is 500r / min;

[0043] (2) Under magnetic stirring conditions, according to the solid-to-liquid ratio g:mL of konjac glucomannan and mixture A ratio of 1:1000, konjac glucomannan was added to mixture A in step (1) to obtain mixture B , the magnetic stirring speed is 500r / min;

[0044] (3) Under magnetic stirring conditions, according to the solid-to-liquid ratio g:mL of sodium h...

Embodiment 3

[0052] A medical porous fiber membrane is prepared by electrospinning with sodium hyaluronate, gelatin, konjac glucomannan and nano-hydroxyapatite as raw materials.

[0053] The preparation method of the medical porous fiber membrane in this embodiment, the specific steps are as follows:

[0054] (1) Under the condition of magnetic stirring, according to the solid-liquid ratio g:mL of gelatin and glacial acetic acid is 1:10, mix gelatin and glacial acetic acid until the gelatin is completely dissolved and no air bubbles can be observed in the liquid to obtain For mixture A, the magnetic stirring speed is 450r / min;

[0055] (2) Under the condition of magnetic stirring, according to the solid-liquid ratio g:mL of konjac glucomannan and mixture A is 1:600, add konjac glucomannan to mixture A in step (1) to obtain mixture B , the magnetic stirring speed is 450r / min;

[0056] (3) Under the condition of magnetic stirring, according to the solid-liquid ratio g:mL of sodium hyaluron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com