(CuIn)xZn2(1-x)S2 nano-particle, preparation method and application thereof

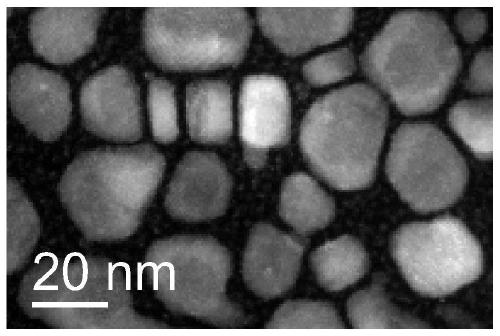

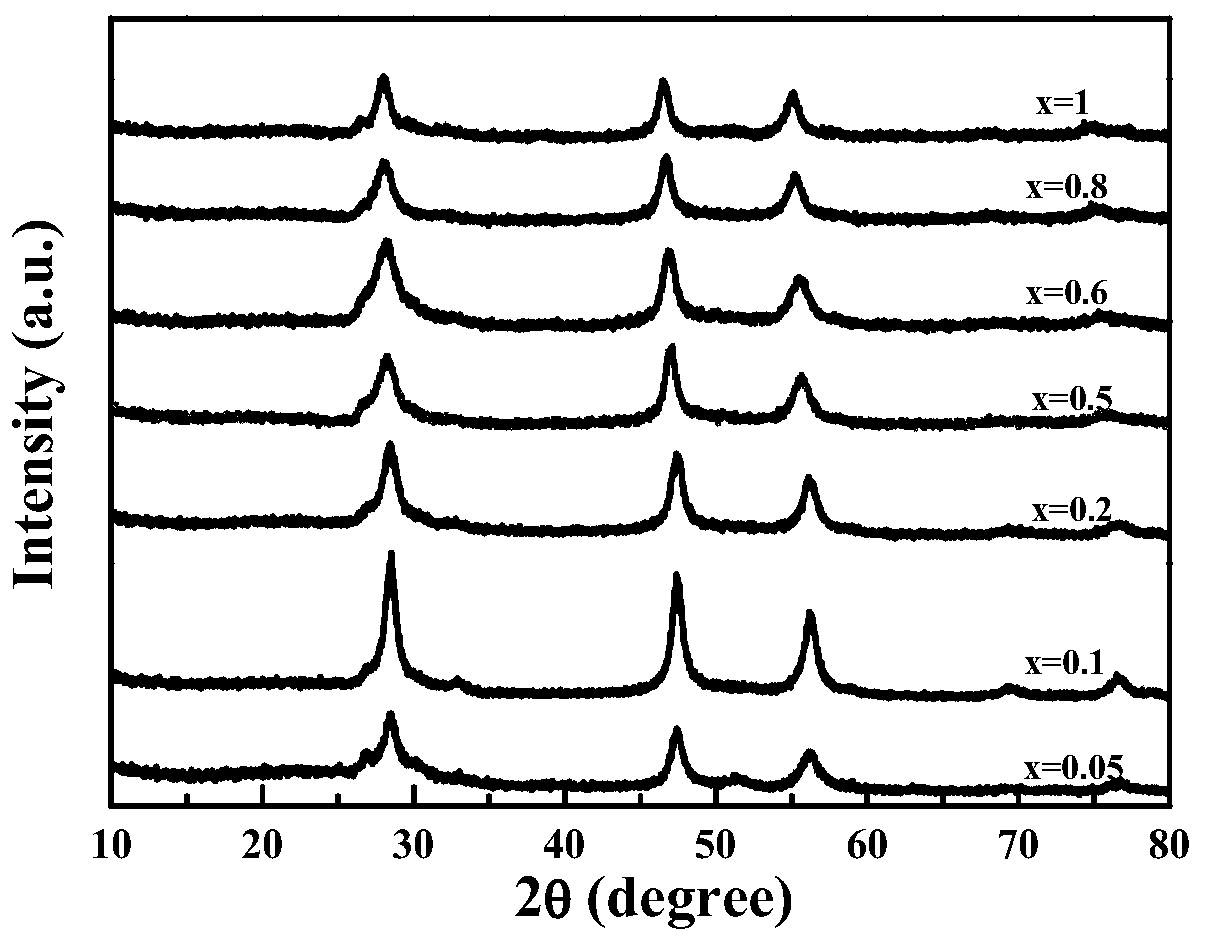

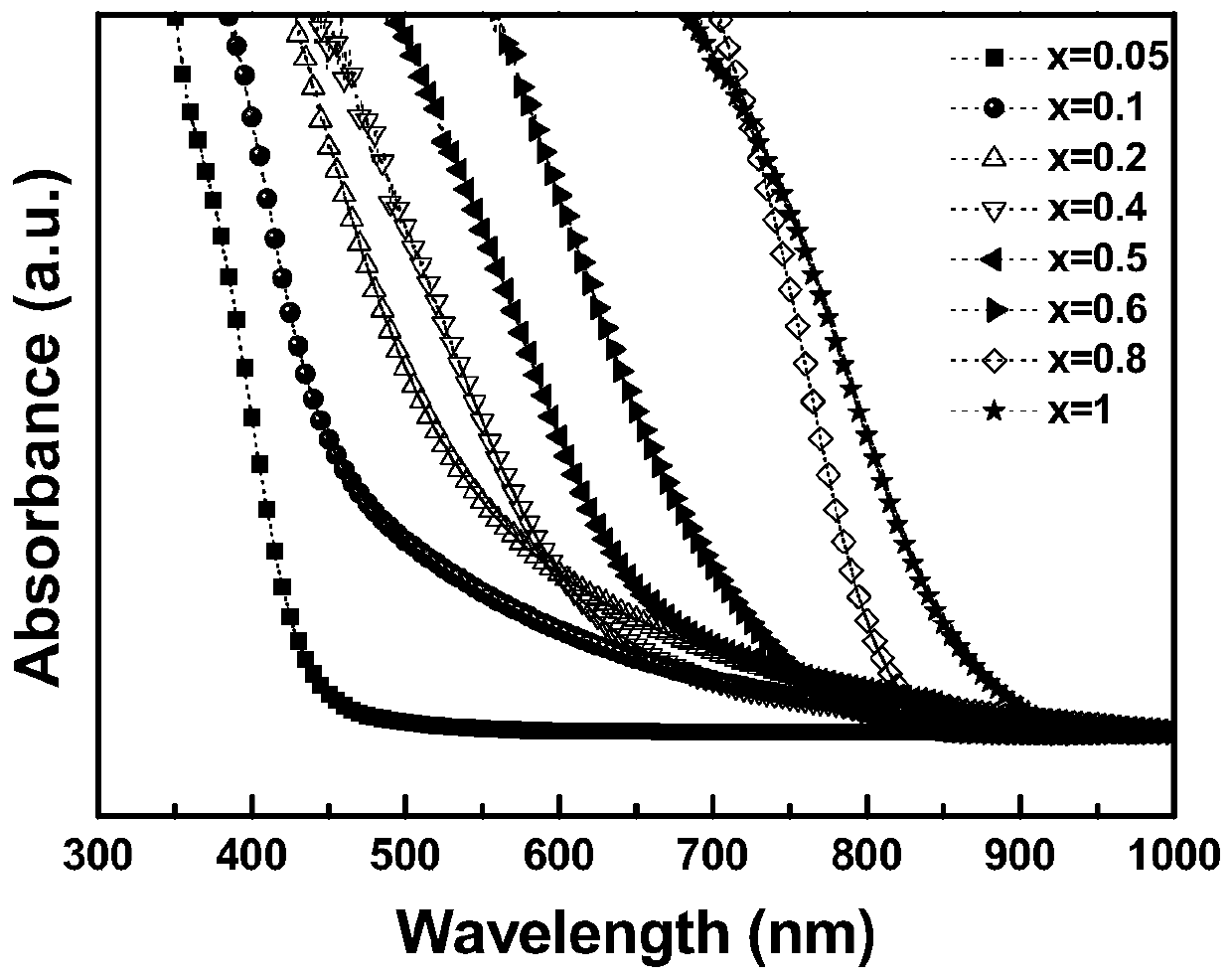

A nanoparticle and cubic phase technology, which is applied in the field of nano-semiconductor material synthesis, can solve the problems of complex operation, high price, and low output, and achieve the effects of large specific surface area, low cost, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (CuIn) of this embodiment 0.05 Zn 1.9 S 2 A method for preparing nanoparticles, comprising the steps of:

[0036] (1) First, 0.1 mmol of copper acetate monohydrate (Cu(CH 3 COO) 2 ·H 2 O), 0.1mmol of indium acetate (In(CH 3 COO) 3 ) and 3.8 mmol of zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O) was poured into a three-necked bottle, put into a drying oven and dried at 120° C. for 10 minutes to remove the moisture in the reagent. Measure 25mL of oleylamine and pour it into a 100mL three-neck bottle. Nitrogen gas is injected into the left bottle mouth, a thermometer is inserted into the right bottle mouth, and a narrow nitrogen gas passage is reserved after the middle bottle mouth is put into a magnet. Blow nitrogen and keep stirring for later use.

[0037] (2) Weigh 4mmol of sulfur powder into a 50mL beaker, then add 10mL of oleylamine dropwise, cover the mouth of the beaker with plastic wrap, put it on a magnetic stirrer, and stir vigorously at 50°C until the...

Embodiment 2

[0042] (CuIn) of this embodiment 0.1 Zn 1.8 S 2 A method for preparing nanoparticles, comprising the steps of:

[0043] (1) First, 0.1 mmol of copper acetate monohydrate (Cu(CH 3 COO) 2 ·H 2 O), 0.1mmol of indium acetate (In(CH 3 COO) 3 ) and 1.8 mmol of zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O) Pour it into a three-neck bottle, put it in a drying oven and dry it at 120° C. for 10 minutes to remove the moisture in the reagent. Measure 22mL of oleylamine and pour it into a 100mL three-neck bottle. Nitrogen gas is introduced into the left bottle mouth, a thermometer is inserted into the right bottle mouth, and a narrow nitrogen gas passage is reserved after the middle bottle mouth is put into a magnet. Blow nitrogen and keep stirring for later use.

[0044] (2) Weigh 4mmol of sulfur powder and pour it into a 50mL beaker, then add 15mL of oleylamine dropwise, cover the mouth of the beaker with plastic wrap, put it on a magnetic stirrer, and stir vigorously until t...

Embodiment 3

[0049] (CuIn) of this embodiment 0.2 Zn 1.6 S 2 A method for preparing nanoparticles, comprising the steps of:

[0050] First, 0.2 mmol of copper acetate monohydrate (Cu(CH 3 COO) 2 ·H 2 O), 0.2mmol of indium acetate (In(CH 3 COO) 3 ) and 1.6mmol of zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O) Pour it into a three-neck bottle, put it in a drying oven and dry it at 120° C. for 10 minutes to remove the moisture in the reagent. Measure 24mL of oleylamine and pour it into a 100mL three-neck bottle. Nitrogen gas is injected into the left bottle mouth, a thermometer is inserted into the right bottle mouth, and a narrow nitrogen gas passage is reserved after the middle bottle mouth is put into a magnet. Blow nitrogen and keep stirring for later use.

[0051] (2) Weigh 4mmol of sulfur powder and pour it into a 50mL beaker, then add 12mL of oleylamine dropwise, cover the mouth of the beaker with plastic wrap, put it on a magnetic stirrer, and stir vigorously until the sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com