Alcohol wastewater treatment technology

A technology of alcohol wastewater and treatment process, which is applied in the fields of food industry wastewater treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

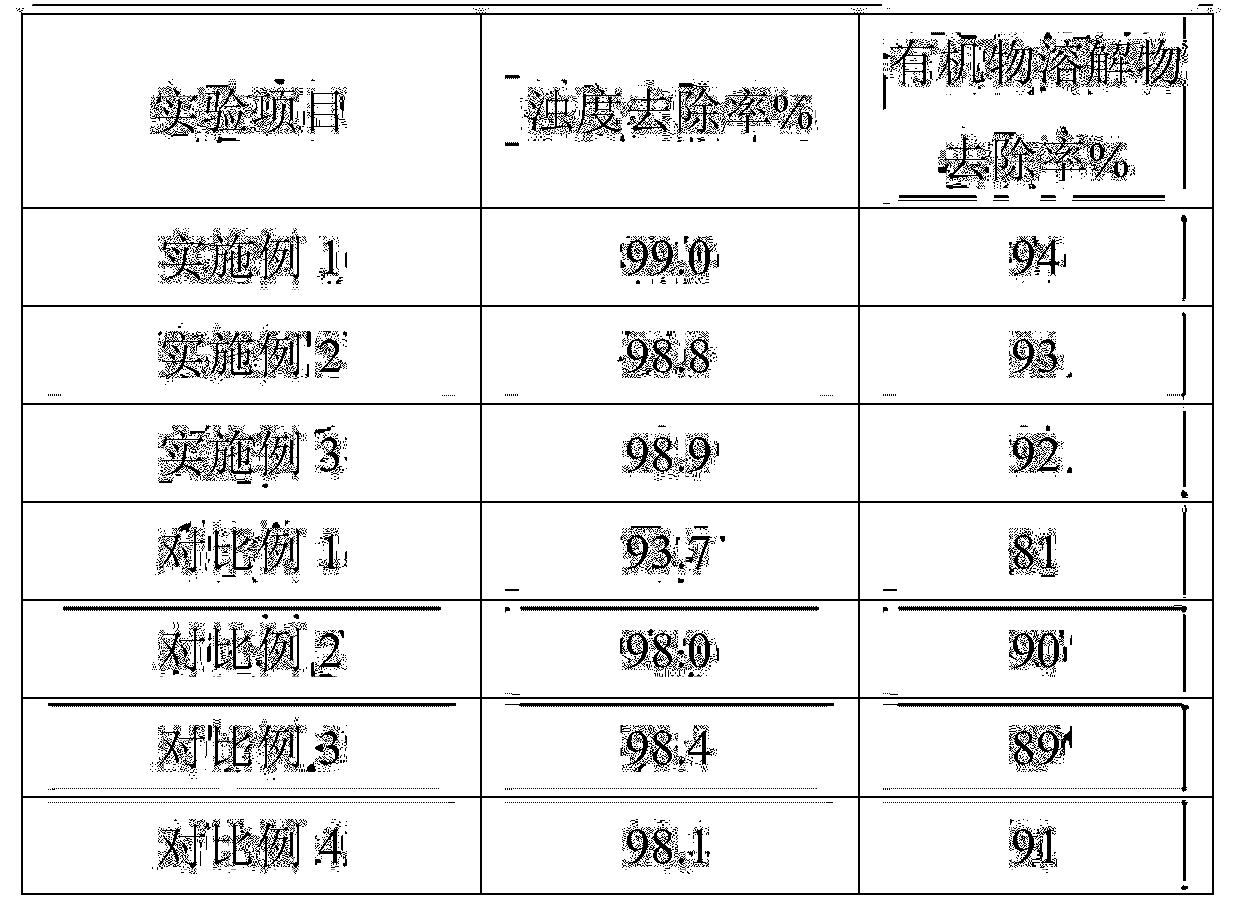

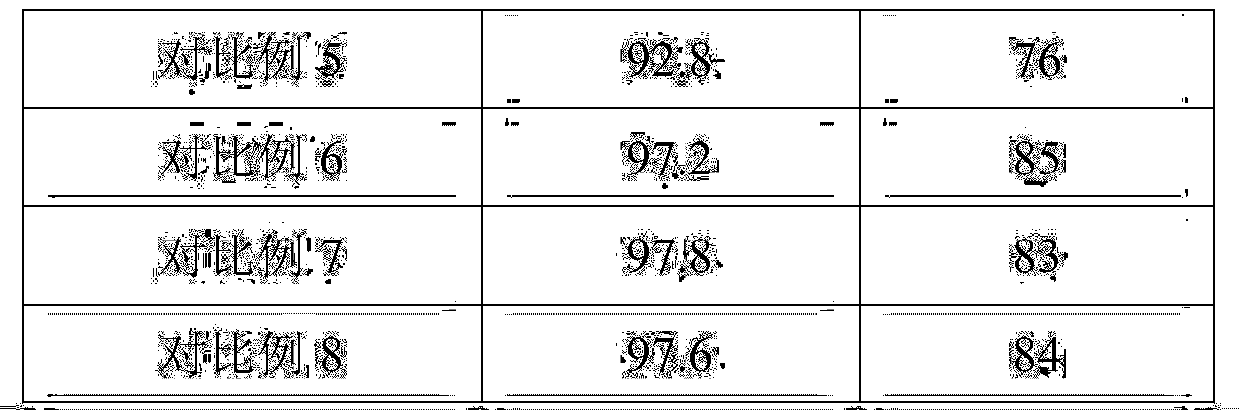

Examples

Embodiment 1

[0026]A kind of alcohol wastewater treatment process, specifically according to the following operation steps: (1) alcohol wastewater enters the adjustment tank after removing larger impurities through the grid, and effectively adjusts the water quantity and quality; (2) then lifts it into the primary sedimentation tank with a pump Carry out pretreatment, at this stage, in order to remove insoluble COD in wastewater, add alcohol wastewater treatment agent to ensure effective removal effect; add alcohol wastewater treatment agent to alcohol wastewater, mix evenly and let stand for 35-45min; (3) After The wastewater enters the hydrolytic acidification tank and the contact oxidation tank for biochemical treatment, and the effluent enters the secondary settling tank for mud-water separation; part of the sludge in the secondary settling tank flows back to the front of the aerobic tank, and part of it is discharged to the sludge tank.

[0027] The alcohol wastewater treatment agent i...

Embodiment 2

[0030] A kind of alcohol wastewater treatment process, specifically according to the following operation steps: (1) alcohol wastewater enters the adjustment tank after removing larger impurities through the grid, and effectively adjusts the water quantity and quality; (2) then lifts it into the primary sedimentation tank with a pump Carry out pretreatment. At this stage, in order to remove insoluble COD in wastewater, add alcohol wastewater treatment agent to ensure effective removal effect; add alcohol wastewater treatment agent to alcohol wastewater, mix evenly and let stand for 40 minutes; (3) After wastewater Enter the hydrolytic acidification tank and contact oxidation tank for biochemical treatment, and the effluent enters the secondary settling tank for mud-water separation; part of the sludge in the secondary settling tank flows back to the front of the aerobic tank, and part of it is discharged to the sludge tank.

[0031] The alcohol wastewater treatment agent include...

Embodiment 3

[0034] A kind of alcohol wastewater treatment process, specifically according to the following operation steps: (1) alcohol wastewater enters the adjustment tank after removing larger impurities through the grid, and effectively adjusts the water quantity and quality; (2) then lifts it into the primary sedimentation tank with a pump Carry out pretreatment, at this stage, in order to remove insoluble COD in wastewater, add alcohol wastewater treatment agent to ensure effective removal effect; add alcohol wastewater treatment agent to alcohol wastewater, mix evenly and let stand for 35-45min; (3) After The wastewater enters the hydrolytic acidification tank and the contact oxidation tank for biochemical treatment, and the effluent enters the secondary settling tank for mud-water separation; part of the sludge in the secondary settling tank flows back to the front of the aerobic tank, and part of it is discharged to the sludge tank.

[0035] The alcohol wastewater treatment agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com