Acetylthiocholine iodide as well as preparation method and application thereof

A technology of iodothioacetylcholine and thioacetic acid, which is applied in the direction of analyzing materials through chemical reactions, observing the influence of chemical indicators on materials, organic chemistry, etc., can solve unfavorable industrial production, intermediates, etc. Harsh conditions, unstable raw materials and other problems, to achieve the effect of excellent clarity, easy to obtain raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

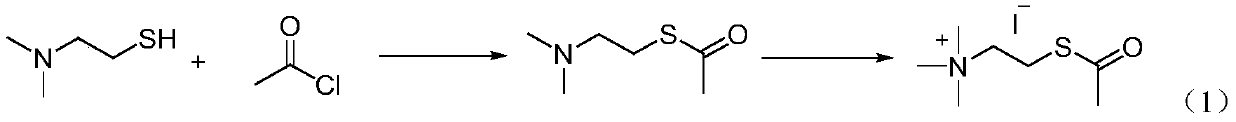

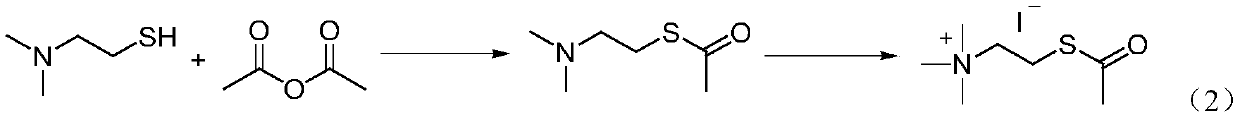

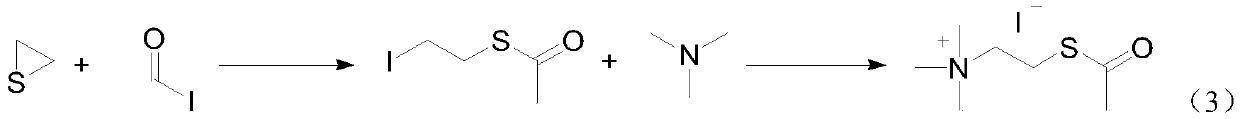

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the iodothioacetylcholine according to the embodiment of the present invention comprises the following steps:

[0039] Step S1, providing an aqueous alkaline solution obtained by dissolving dimethylaminoethane compounds in alkali.

[0040] Wherein, the dimethylaminoethane compound refers to dimethylaminoethane and its derivatives, specifically, may include dimethylaminoethane, dimethylaminochloroethane, dimethylaminobromoethane, or a mixture thereof , wherein, preferably dimethylaminobromoethane.

[0041] The base is not particularly limited, for example, it can be an organic base or an inorganic base, preferably an inorganic base, such as sodium carbonate, potassium carbonate, sodium bicarbonate, potassium bicarbonate, sodium hydroxide, potassium hydroxide, or a mixture thereof.

[0042] Step S2, adding a thioacetic acid compound to the alkaline aqueous solution to cause a thio reaction with the dimethylaminoethyl compound to generate dimethy...

Embodiment 1

[0066] In a 5L three-necked flask, take by weighing 121.6g of potassium carbonate and place in the bottle, add 1.5L of water, stir and dissolve, then add 150.8g of dimethylaminobromoethane hydrochloride to it, make it all free, and get a clear solution. Cool down to 5-10°C in an ice-salt bath, add 136.8g potassium thioacetate to the bottle, after the addition is complete, stir at room temperature (25°C) for 6 hours, during which time the solid state of the system and the color of the system will change from white to brown.

[0067] After completion of the reaction, add 2L ethyl acetate to the system, extract and separate the liquids, and the obtained organic phase is dried with anhydrous magnesium sulfate, suction filtered, and the filtrate is concentrated to obtain intermediate dimethylaminoethyl thioacetic acid 130g.

[0068] Into a 2L three-necked flask, add 130g of the above-mentioned intermediate and 1.3L of tetrahydrofuran, control the temperature, and add 144.6g of methy...

Embodiment 2

[0075] In a 5L three-neck flask, weigh 17.6g of sodium hydroxide and place it in the bottle, add 1.5L of water, stir to dissolve, then add 150.8g of dimethylaminobromoethane hydrochloride to it, make it all free, and obtain a clear solution . Cool down to 5-10°C in an ice-salt bath, add 136.8g potassium thioacetate to the bottle, after the addition is complete, stir at room temperature (25°C) for 6 hours, during which the solid state and color of the system will change from white to brown.

[0076] After completion of the reaction, add 2L ethyl acetate to the system, extract and separate the liquids, and the obtained organic phase is dried with anhydrous magnesium sulfate, suction filtered, and the filtrate is concentrated to obtain intermediate dimethylaminoethyl thioacetic acid 120g.

[0077] Into a 2L three-necked flask, add 120g of the above-mentioned intermediate and 1.2L of tetrahydrofuran, control the temperature, and add 133.5g of methyl iodide dropwise at about 20°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com