Method for preparing double-responsiveness nanometer microsphere through mercaptan-alkene visible light emulsion polymerization and double-responsiveness nanometer microsphere

A nano-microsphere and emulsion polymerization technology, applied in the field of functional and intelligent polymer materials, can solve the problem of high energy consumption of UV light, and achieve the effects of environmental protection, fast reaction speed, safety, environmental protection and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A. Take trimethylolpropane tris(3-mercaptopropionate), allyl methacrylate, tri(ethylene glycol) divinyl ether, hexadecane and 1,4-benzenediol, add azridine The mixture of pyridine orange and diphenyliodonium hexafluorophosphate was stirred at 15°C for 2h at a stirring speed of 250 rpm to obtain an oil phase solution;

[0069] B, after adding the mixed solution of cetyltrimethylammonium bromide and triethylenetetramine to the oil phase solution obtained in step A, carry out ultrasonic emulsification, the time of ultrasonic emulsification is 1h, the frequency of ultrasonic is 8MHz, the ultrasonic emulsification Strength is 8W / cm 2 Obtain pre-emulsion;

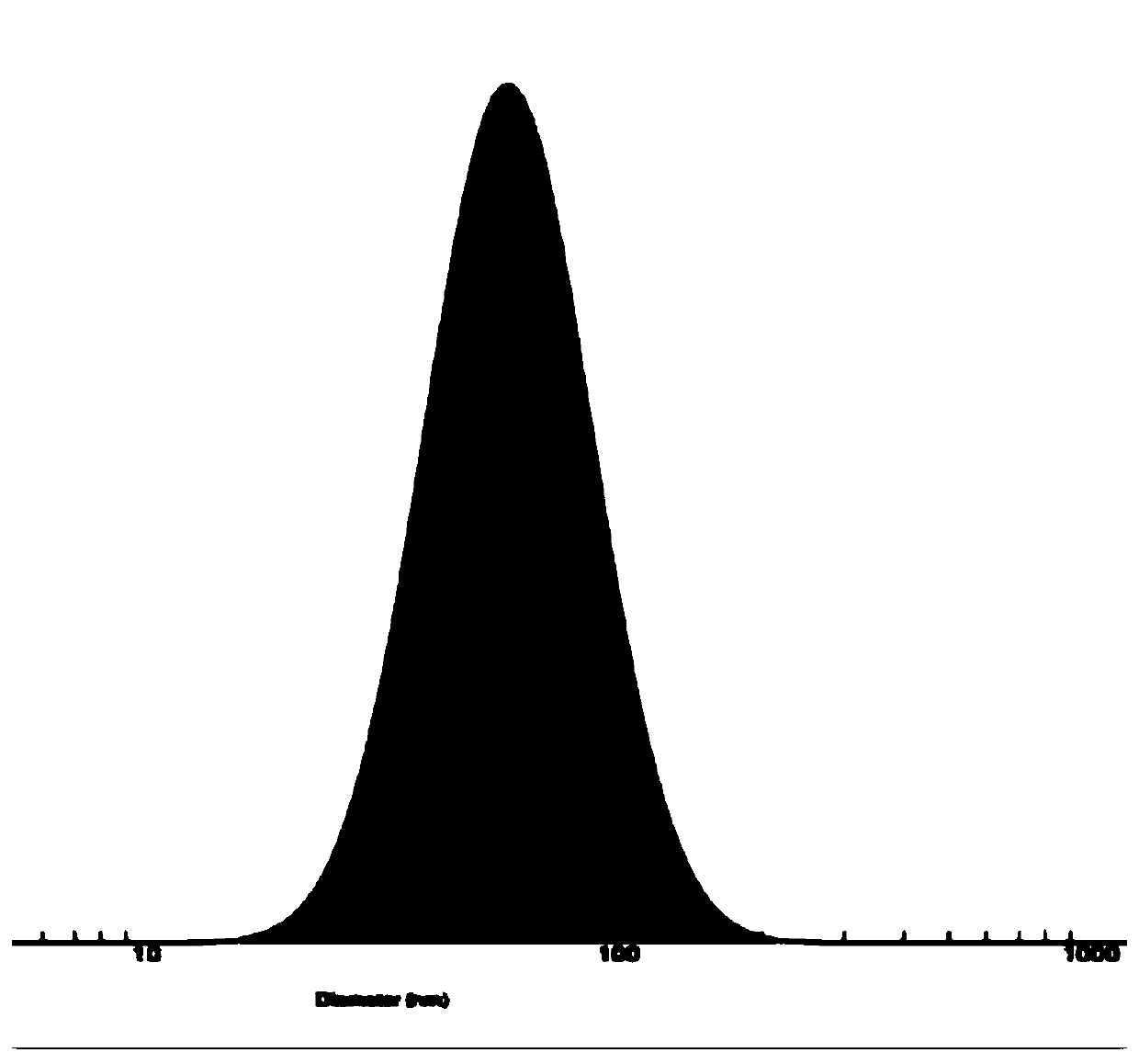

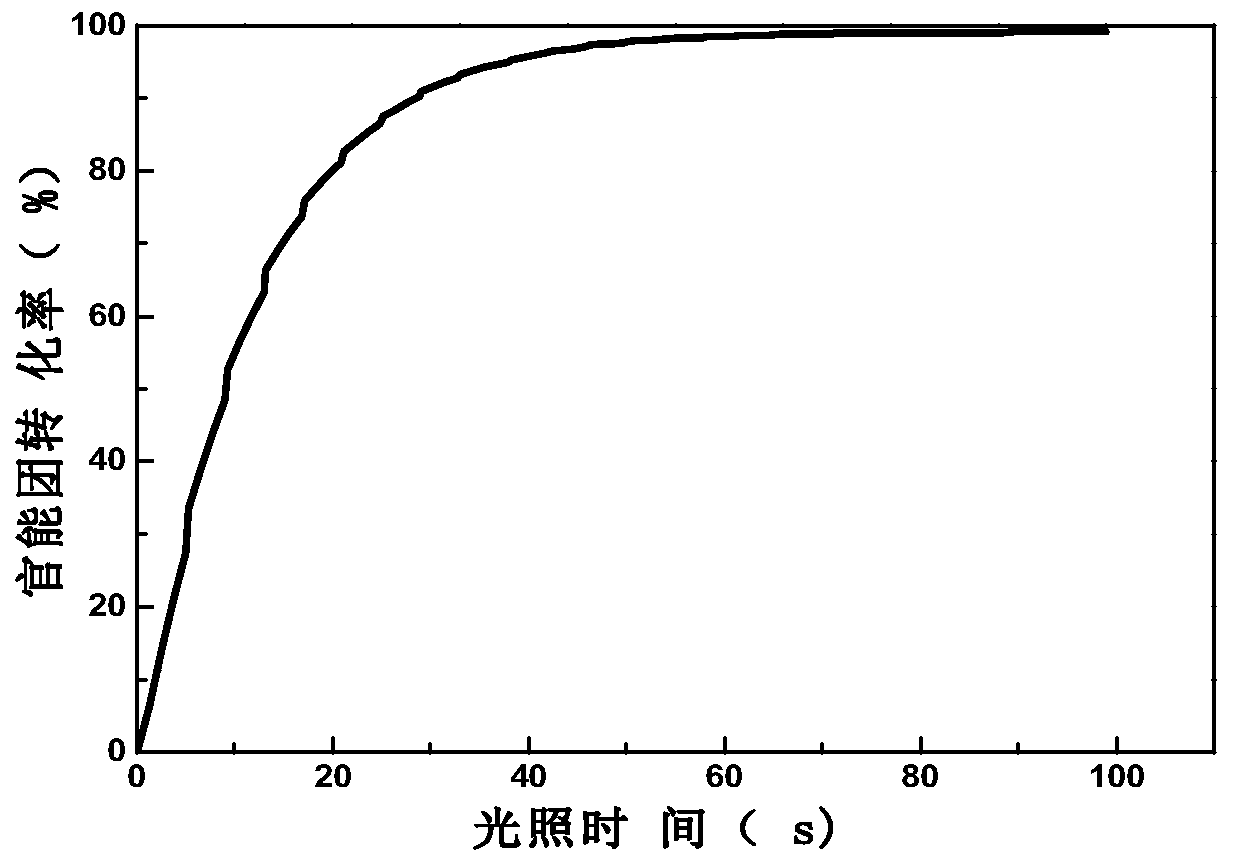

[0070] C. At 15°C, irradiate the pre-emulsion obtained in step B by LED, the LED irradiation time is 5min, the wavelength of the LED is 390nm, the peak radiation value is 50nm, and the light intensity is 40mW / cm -2 Obtain double responsive polymer nanosphere emulsion;

[0071] D, the dual responsive polymer nano-microsp...

Embodiment 2

[0075] A. Take trimethylolpropane tris(3-mercaptopropionate), allyl methacrylate, tri(ethylene glycol) divinyl ether, hexadecane and 1,4-benzenediol, add Irgacure 784 was stirred at 15°C for 2 hours at a stirring speed of 250 rpm to obtain an oil phase solution;

[0076] B, after adding the mixed solution of cetyltrimethylammonium bromide and triethylenetetramine to the oil phase solution obtained in step A, carry out ultrasonic emulsification, the time of ultrasonic emulsification is 1h, the frequency of ultrasonic is 8MHz, the ultrasonic emulsification Strength is 8W / cm 2 Obtain pre-emulsion;

[0077] C. At 15°C, irradiate the pre-emulsion obtained in step B by LED, the LED irradiation time is 5min, the wavelength of the LED is 390nm, the peak radiation value is 50nm, and the light intensity is 40mW / cm -2 Obtain double responsive polymer nanosphere emulsion;

[0078] D, the dual responsive polymer nano-microsphere emulsion obtained in step C is centrifuged for 3min, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com