Automobile armrest box, and preparation method thereof

A technology for automobile armrests and armrest boxes, which can be applied to armrests, passenger spaces, etc., and can solve problems such as poor anti-mildew and antibacterial properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of automobile armrest box of the present invention comprises the following steps:

[0035] a. Heat high-density polyethylene and polytetrafluoroethylene to 140-160°C, keep it warm for 20-40min, then add polycarbonate, dialkyl phosphoric acid, polyethylene glycol, magnesium carbonate, nano-montmorillonite, nitric acid Mix calcium, carbon black, graphite, hydroxyapatite and nano silicon dioxide evenly, continue to heat up to 180-220°C, keep warm for 5-15min, stir at 3500-5500r / min for 1-2h, cool to room temperature to obtain the base material ;

[0036] b. Mix polypropylene and styrene evenly, raise the temperature to 80-120°C, keep it warm for 10-30min, then under the protection of nitrogen, reflux at 110-130°C for 4-8h, then cool to room temperature, add diisopropyl peroxide Mix benzene evenly, wash and dry by rotary evaporation to constant weight, cool to room temperature, then add chloroform and mix evenly, blend at 160-200°C for 10-20min, cool...

Embodiment 1

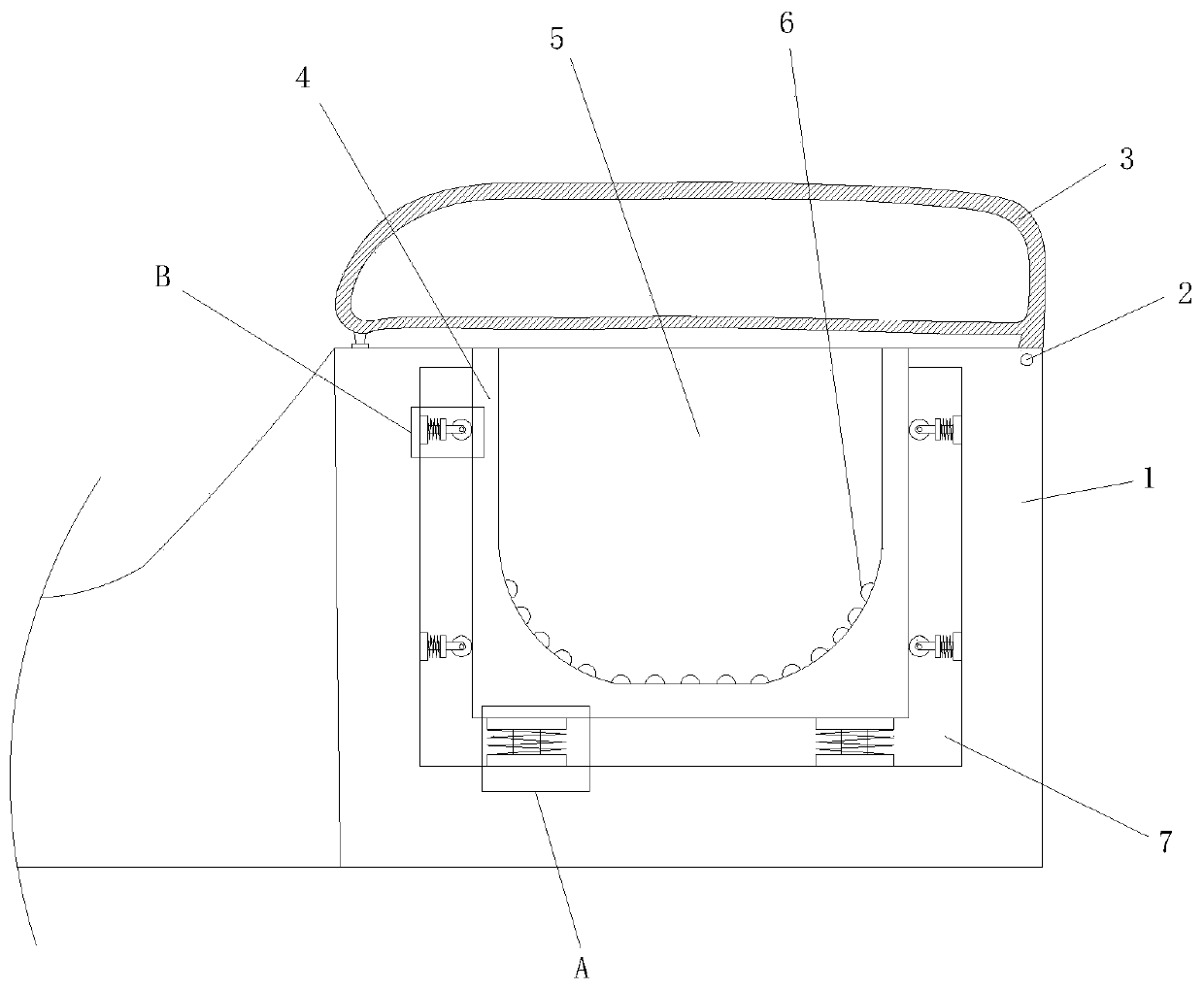

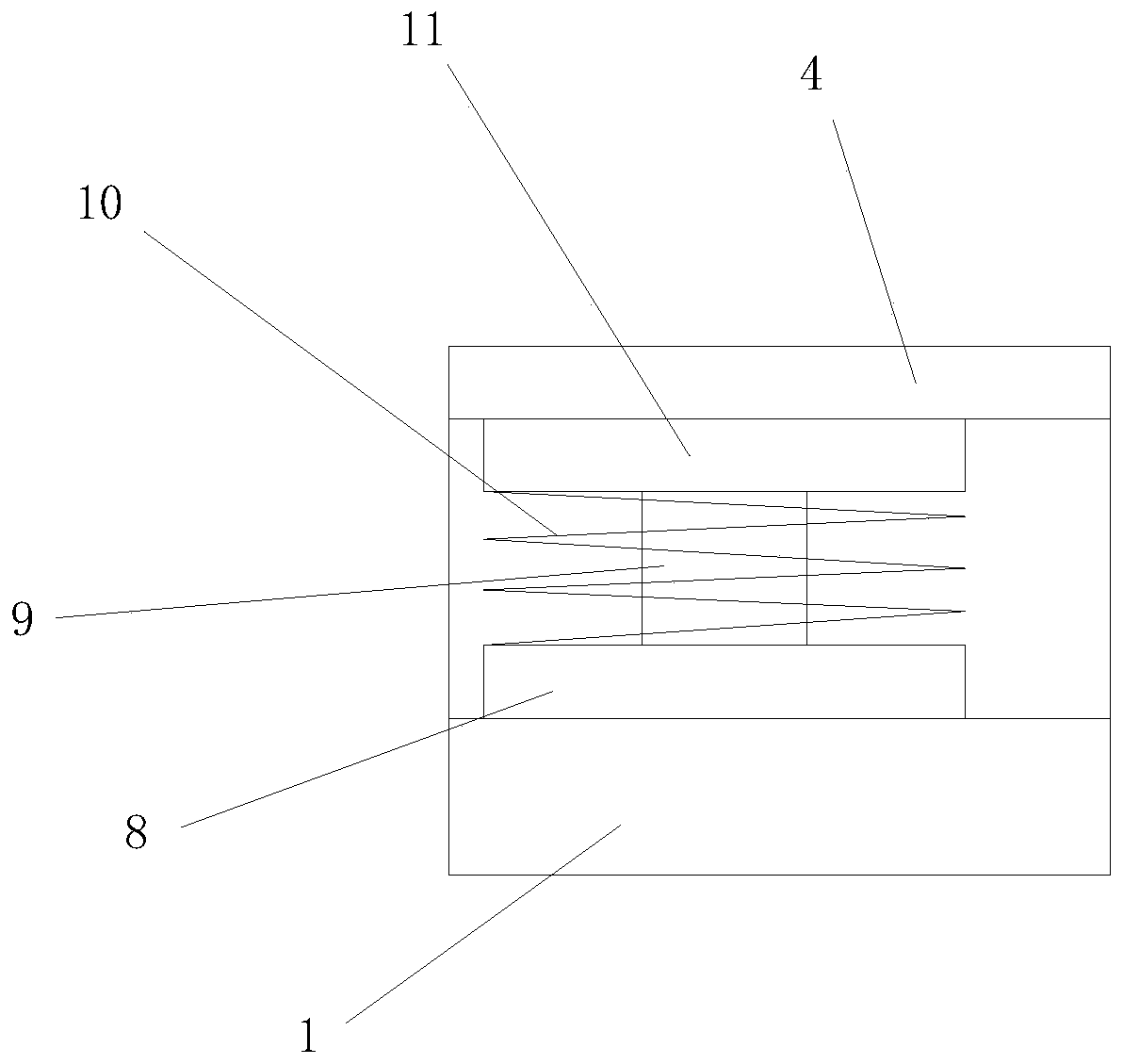

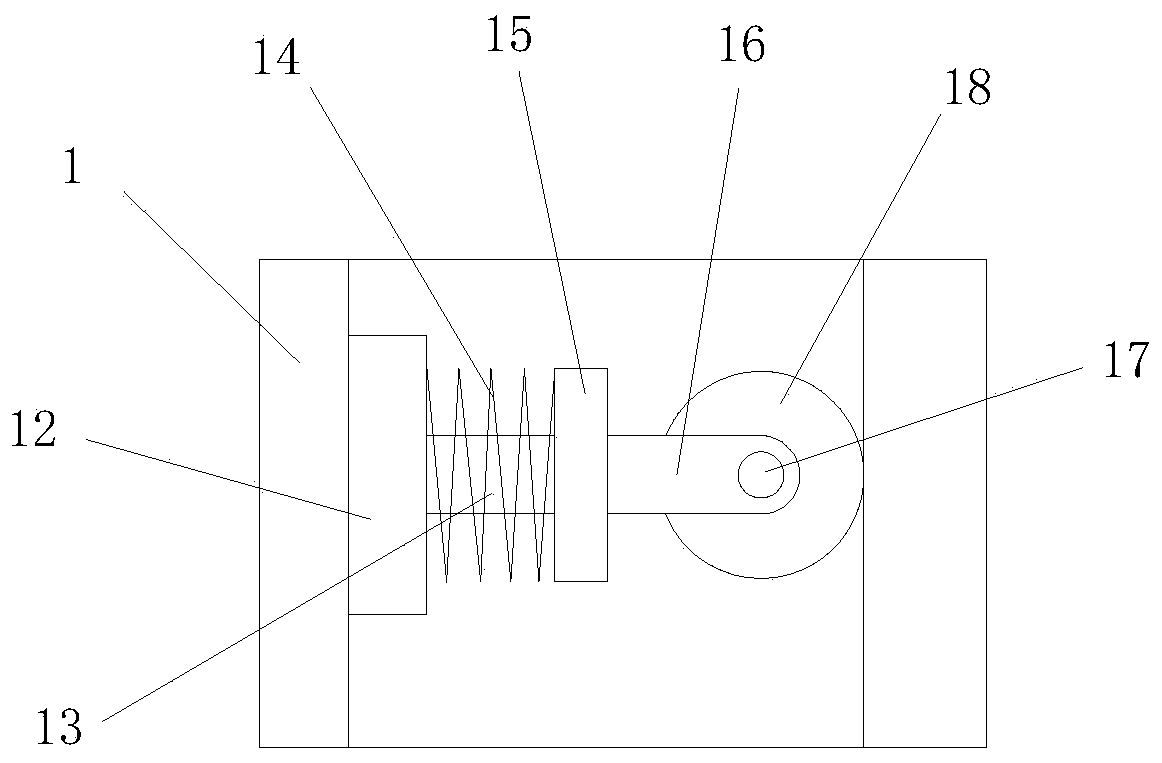

[0041] refer to Figure 1-3 As shown, the automobile armrest box includes an armrest box body 1, a cover plate 3 that can be clamped on the armrest box body is installed on the armrest box body 1 through a hinge 2, and a glove box body is arranged inside the armrest box body 1 4. The storage box body 4 is provided with a storage slot 5, the armrest box body 1 is provided with a mounting groove 7, and the side of the storage box body 4 close to the mounting slot 7 is installed with a second piston 11, the The side of the second piston 11 away from the glove box body 4 is equipped with a first piston shaft 9, and the side of the first piston shaft 9 away from the second piston 11 is equipped with a first piston 8, and the first piston 8 is installed on Armrest box body 1. A first spring 10 is provided between the first piston 8 and the second piston 11 , and the first spring 10 is sleeved on the outer circumference of the first piston shaft 9 . The side of the armrest box body...

Embodiment 2

[0050] refer to Figure 1-3 As shown, the automobile armrest box includes an armrest box body 1, a cover plate 3 that can be clamped on the armrest box body is installed on the armrest box body 1 through a hinge 2, and a glove box body is arranged inside the armrest box body 1 4. The storage box body 4 is provided with a storage slot 5, the armrest box body 1 is provided with a mounting groove 7, and the side of the storage box body 4 close to the mounting slot 7 is installed with a second piston 11, the The side of the second piston 11 away from the glove box body 4 is equipped with a first piston shaft 9, and the side of the first piston shaft 9 away from the second piston 11 is equipped with a first piston 8, and the first piston 8 is installed on Armrest box body 1. A first spring 10 is provided between the first piston 8 and the second piston 11 , and the first spring 10 is sleeved on the outer circumference of the first piston shaft 9 . The side of the armrest box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com