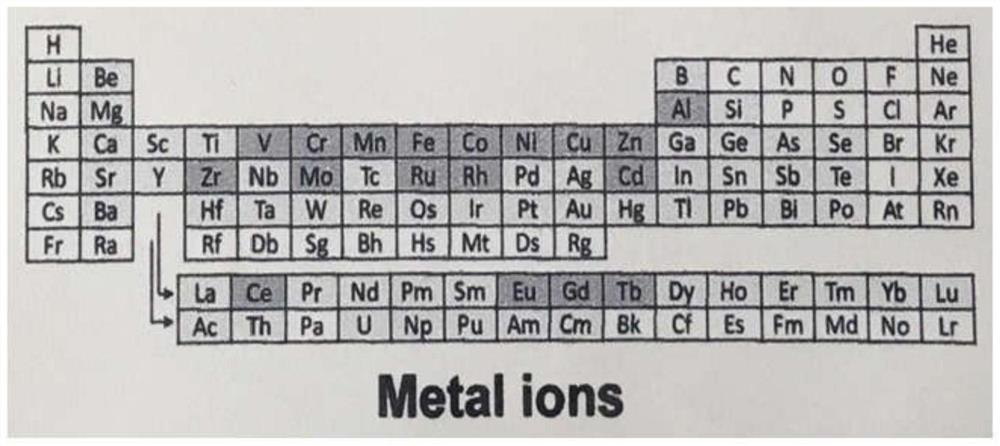

A recyclable color development method based on metal-polyphenol network structure

A network structure and metal technology, applied in the fields of printing, printing, and writing, can solve the problems of waste paper that is not easy to decolorize, easy to clog the tip of the pen, and difficult to decolorize the colorant, etc., and achieves a simple and easy treatment method, which is conducive to recycling and good chemistry. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

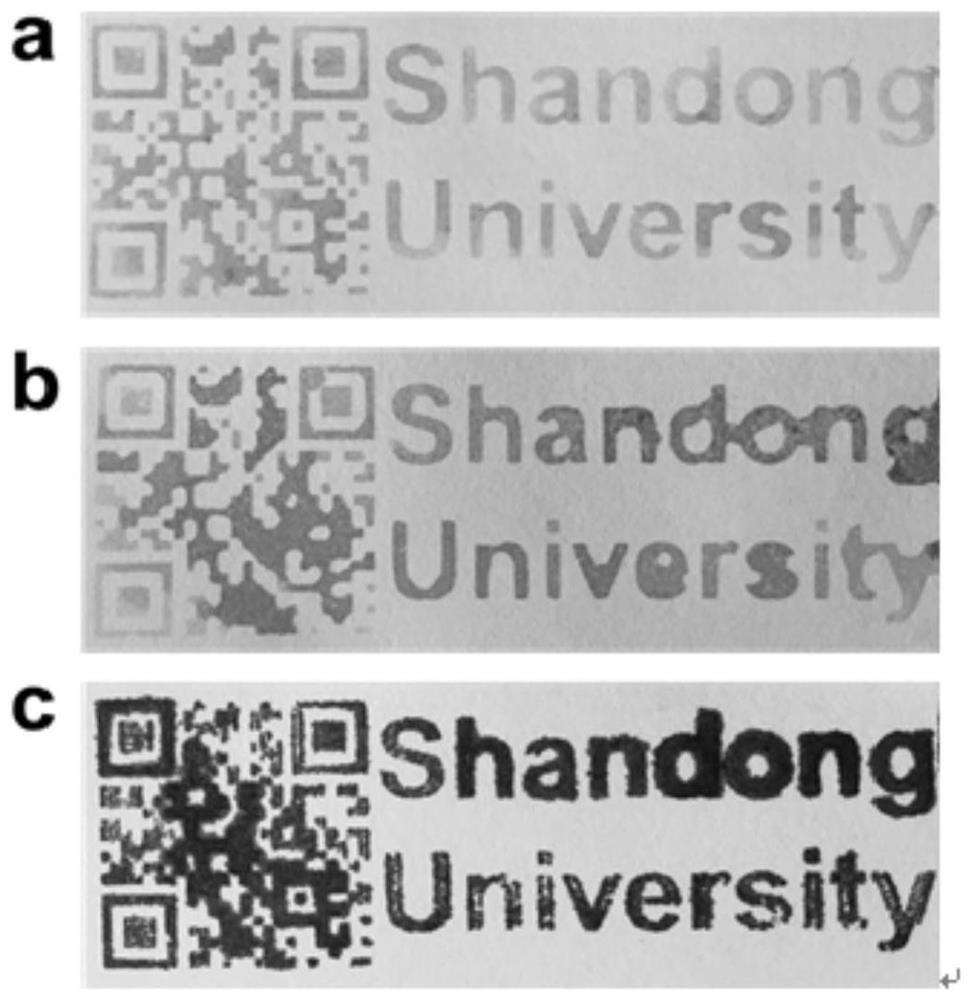

[0044] Embodiment 1 can recycle black and white inkjet printing

[0045] (1) Dissolve 1g of tannic acid in 10mL of ethanol, polyphenol solution, and spray the polyphenol solution on the surface of A4 printing paper in a watering can, ventilate and dry naturally at room temperature;

[0046] (2) Dissolve 2g of ferric chloride hexahydrate in 10mL of ethanol to obtain a color-developing ink, and inject the color-developing ink into an empty ink cartridge (HP803) of an ordinary inkjet printer (HP Desk Jet 1112) with a syringe;

[0047] (3) Connect the computer to the printer normally, install the ink cartridge containing the chromogenic ink into the printer, put the dried printing paper treated with the polyphenol solution into the printer paper storage box, select the document to be printed, and print in black and white.

[0048] The printing effect of embodiment 1 is as follows figure 1 shown.

Embodiment 2

[0049] Embodiment 2 recyclable color stamps

[0050] (1) 1g of tannic acid is dissolved in 10mL of ethanol, and the polyphenol solution is sprayed on the surface of the adhesive paper in a watering can, and the room temperature is ventilated and dried naturally;

[0051] (2) Add 8 mL of water to two (2-hydroxypropionic acid) diammonium dihydroxide titanium solution (50wt.% aqueous solution, 2 mL); 1 g of copper sulfate pentahydrate and 1 g of ferric chloride hexahydrate are dissolved in In 10mL of water, the colored inks of yellow, brown and black stamps were obtained.

[0052] (3) Use a brush to paint different colors of color-developing inks onto the dry surface of the stamp, and then print clear icons of corresponding colors on the above-mentioned adhesive paper treated with tannic acid. The stamp effect is as figure 2 shown.

Embodiment 3

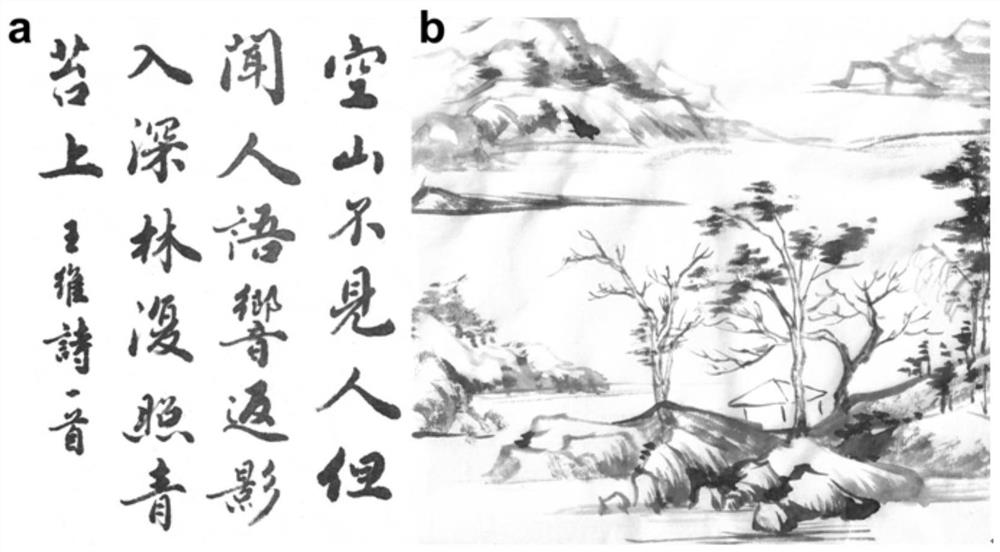

[0053] Embodiment 3 can recycle soft brush calligraphy, painting

[0054] (1) 1g of tannic acid is dissolved in 10mL of ethanol, and the polyphenol solution is sprayed on the surface of the rice paper in a watering can, and the room temperature is ventilated and dried naturally;

[0055] (2) 1.5g ferric chloride hexahydrate, 1.5g copper sulfate pentahydrate (being dissolved in 10mL ethanol volume fraction respectively in the water / ethanol mixed solution of 10%; Add 7mL of water to diammonium titanium oxide solution (50wt.% aqueous solution, 3mL) to obtain black, brown, and yellow color-developing inks respectively;

[0056] (3) Dip black ink with a brush, and perform calligraphy and ink painting on the rice paper processed in step (1) (effects such as image 3 Shown), when you need to add other colors to the painting, replace the brush or clean the brush and dip it in brown or yellow ink for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com