Anti-corona acrylic acid conductive coating as well as preparation method and application thereof

A conductive coating, acrylic technology, applied in conductive coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of poor environmental protection of conductive coatings, insufficient toughness of acrylic conductive coatings, etc. The effect of halo generation and repair of surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A kind of preparation method of anti-corona acrylic conductive paint for ultra-high voltage substation wire of the present invention comprises the following steps:

[0043] (a) using an organic solvent to dissolve the acrylic matrix resin to prepare an acrylic acid solution; (b) pre-dispersing carbon nanotubes; (c) weighing the acrylic acid solution and carbon nanotubes in the above steps (a) and (b) according to the above preset mass ratio After the dispersion liquid is mixed evenly, carbon fiber powder treated with coupling agent, nano-titanium dioxide and leveling agent are added to obtain a mixed liquid, and the obtained mixed liquid is coated on the surface of a high-voltage wire to form an acrylic conductive coating.

[0044] Specifically, step (a) uniformly mix the organic solvent and the acrylic resin particles to obtain an acrylic acid solution; the solid content of the acrylic acid solution is 20%-60%.

[0045] (b) putting the carbon nanotubes into the solvent...

Embodiment 1

[0049] An anti-corona acrylic conductive coating comprises, in parts by weight, 10 parts of acrylic resin, 40 parts of carbon fiber powder, 1 part of coupling agent, 1 part of carbon nanotube, 2 parts of nano titanium dioxide and 1 part of leveling agent. The preparation process includes the following steps: step (a) uniformly mixing organic solvent and acrylic resin particles to obtain an acrylic acid solution with a solid content of 20% to 60%; (b) putting carbon nanotubes into ethanol solution, After fully stirring for 12 to 24 hours at °C, ultrasonic treatment at 40 to 60°C for 12 to 24 hours to obtain a 1 to 30 wt% carbon nanotube dispersion; (c) weighing the acrylic acid solution and After the carbon nanotube dispersion is mixed evenly, the carbon fiber powder treated with the coupling agent, nano-titanium dioxide and leveling agent are added, and the mixed solution is obtained after fully stirring, and the obtained mixed solution is coated on the surface of the high-volt...

Embodiment 2

[0051] An anti-corona acrylic conductive coating comprises, in parts by weight, 30 parts of acrylic resin, 40 parts of carbon fiber powder, 1 part of coupling agent, 1 part of carbon nanotube, 2 parts of nano titanium dioxide and 1 part of leveling agent. The preparation process includes the following steps: the preparation process includes the following steps: step (a) uniformly mixing the organic solvent and acrylic resin particles to obtain an acrylic acid solution with a solid content of 20% to 60%; (b) putting carbon nanotubes into ethanol solution, fully stirred at 30-50° C. for 12-24 hours, and then ultrasonically treated at 40-60° C. for 12-24 hours to obtain a 1-30 wt % carbon nanotube dispersion; (c) weighing the above steps (a), and (b) The acrylic acid solution and the carbon nanotube dispersion liquid are mixed evenly, and then the carbon fiber powder, nano-titanium dioxide and leveling agent treated by the coupling agent are added, and the mixed solution is obtain...

PUM

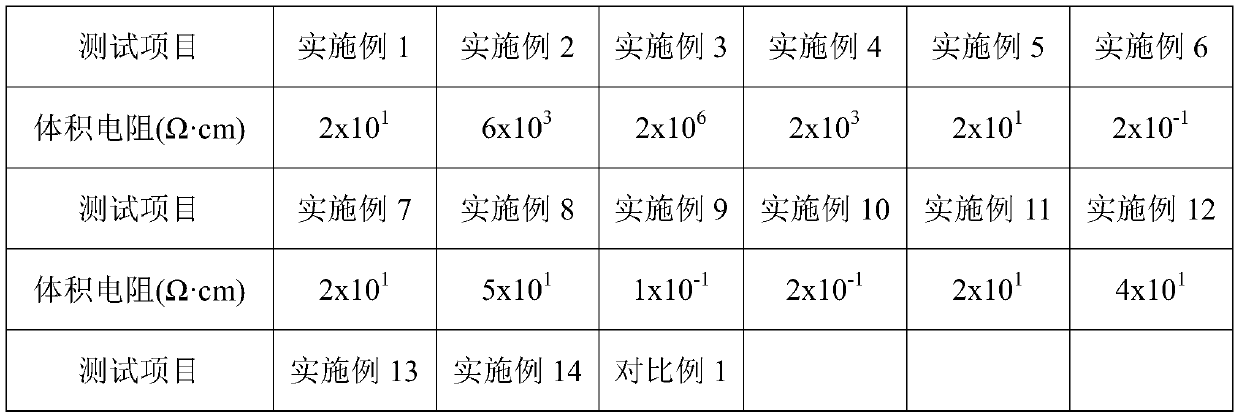

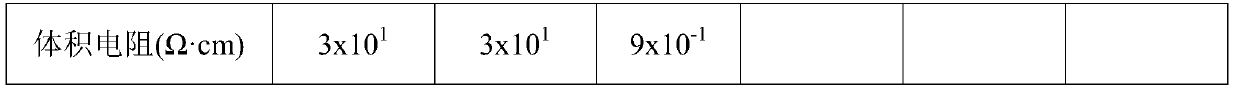

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Volume resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com