Processing method of cobalt carbonate mother liquor in cobalt powder precursor cobalt carbonate preparation process

A technology of cobalt carbonate mother and treatment method, which is applied in the field of metallurgy, can solve the problems of increasing the impurity content of by-product ammonium chloride, cobalt is not effectively recovered, and the quality of by-products is reduced, so as to reduce the amount, improve the recovery rate, and reduce operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

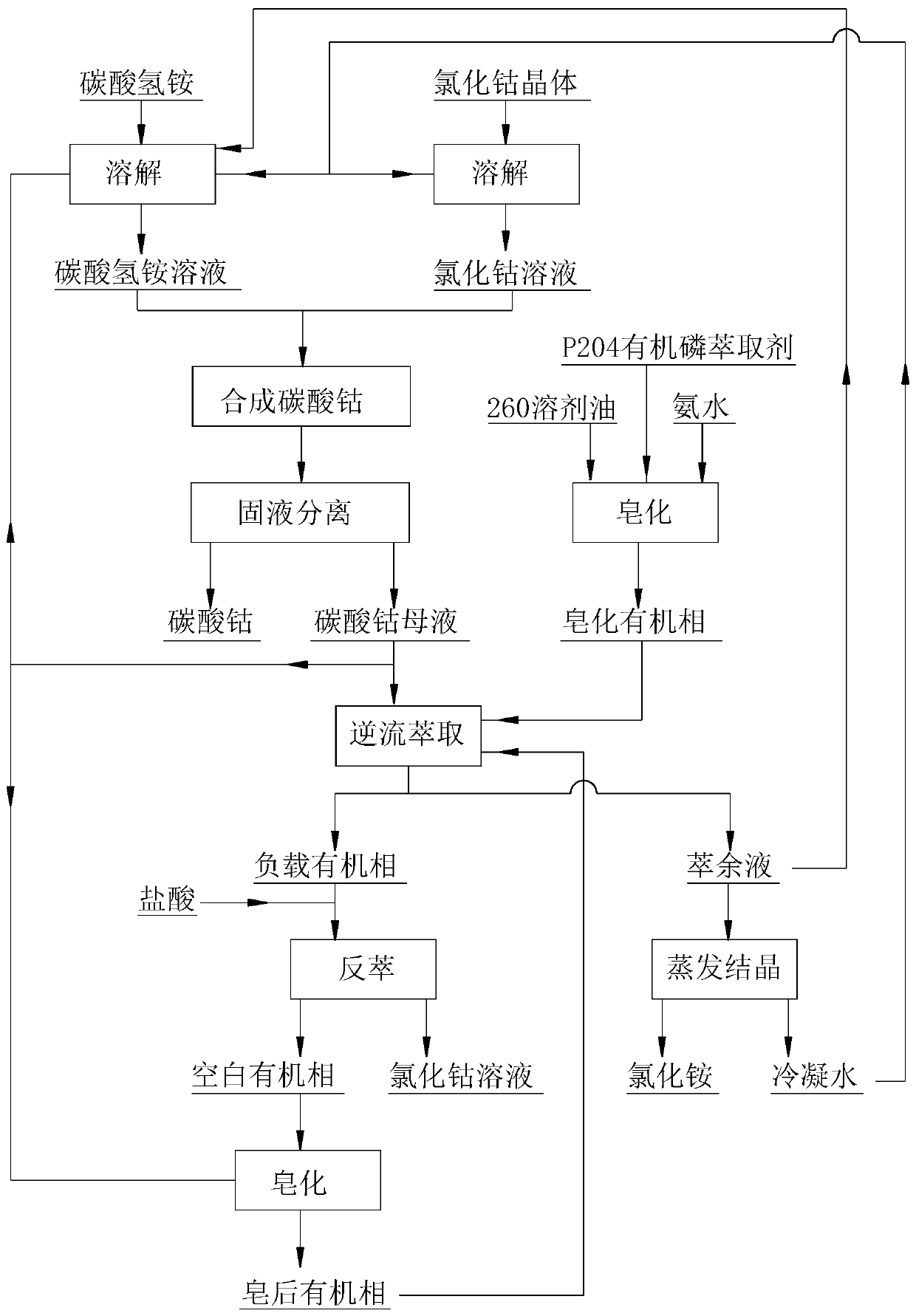

[0024] This implementation combines the overall preparation process of cobalt carbonate to further describe the treatment method in the present invention in detail.

[0025] refer to figure 1 , first ammonium bicarbonate and cobalt chloride crystals are prepared into solutions with pure water respectively, wherein the concentration of the ammonium bicarbonate solution is 200g / L, and the concentration of the cobalt chloride solution is 120g / L. Then first add the ammonium bicarbonate solution into the reaction kettle, and then add the cobalt chloride solution into the reaction kettle at 40°C to react to synthesize cobalt carbonate. After reacting for 150 minutes, control the end point pH=7.0-7.2 to produce carbonic acid cobalt slurry; then the cobalt carbonate slurry is press-filtered with a filter press, and the filtrate is taken as cobalt carbonate mother liquor, and the main component of the filter residue is cobalt carbonate. It can be understood that in other embodiments, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com