Preparation method of large-size single crystal beta-gallium oxide nanobelt structure

A gallium nitride nanotechnology, gallium oxide technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of uncontrollable growth direction, different crystal phases of nanomaterials, etc., to achieve universality and good repeatability , Reduce the time required, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

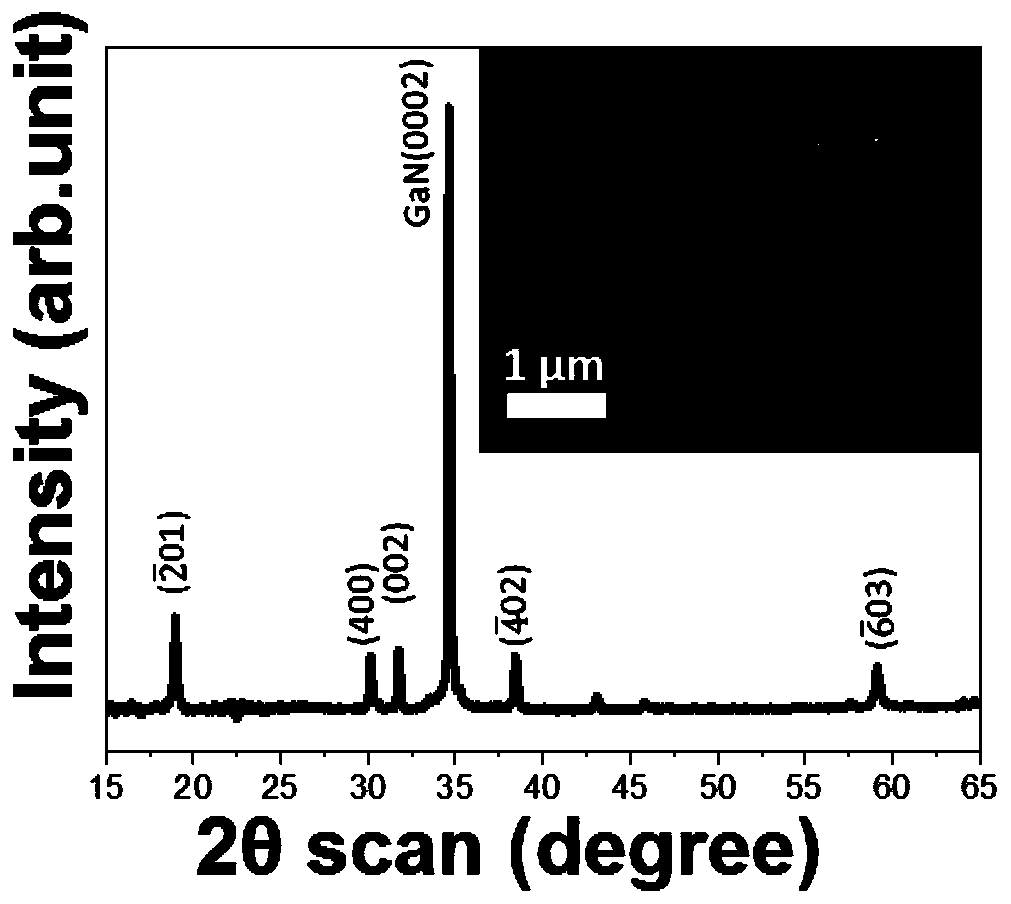

[0058] Example 1: Preparation of (-201) single crystal β-gallium oxide nanowires.

[0059] (1) A thin layer of platinum is plated on the gallium nitride film:

[0060] Before the gallium oxide nanostructure is grown on the gallium nitride film, an 8nm-thick platinum thin layer is evaporated on the gallium nitride surface.

[0061] (2) Place the gallium nitride film into the chemical vapor deposition equipment, and form catalytic particles on the surface of the gallium nitride film by annealing:

[0062] Put the gallium nitride film in step (1) into the CVD chamber, and the pressure in the chamber of the chemical vapor deposition equipment is stabilized at 1.01×10 5 Pa, flow argon gas with a flow rate of 300 sccm, raise the temperature to 800°C, and maintain the temperature for annealing for 30min.

[0063] (3) Annealing in a low-oxygen environment to form gallium nitride nanoseed crystals wrapped with catalytic particles on the film:

[0064] Inject 400 sccm of argon gas fo...

Embodiment 2

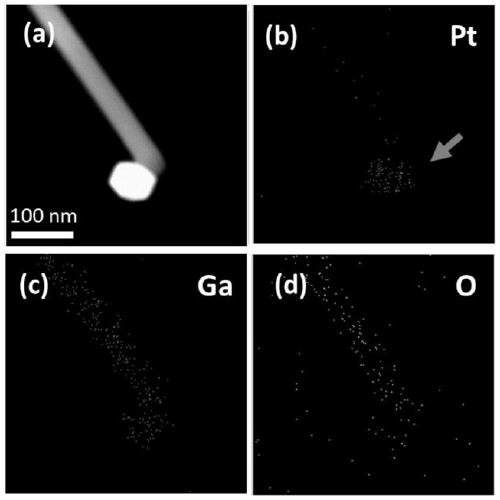

[0068] Embodiment 2: Single crystal β-gallium oxide nanobelt and device.

[0069] (1) A thin layer of platinum is plated on the gallium nitride film:

[0070] Before the gallium oxide nanostructure is grown on the gallium nitride film, 4nm, 6nm, and 8nm thick platinum thin layers are respectively evaporated on the surface of the gallium nitride.

[0071] (2) Place the gallium nitride film into the chemical vapor deposition equipment, and form platinum particles on the surface of the gallium nitride film by annealing:

[0072] Put the gallium nitride film in step (1) into the CVD chamber, and the pressure in the chamber of the chemical vapor deposition equipment is stabilized at 1.01×10 5 Pa, flow argon gas with a flow rate of 100 sccm, raise the temperature to 500°C, and maintain the temperature for annealing for 60min.

[0073] (3) Annealing in a low-oxygen environment to form gallium nitride nanoseed crystals wrapped with platinum particles on the film:

[0074] Evacuate ...

Embodiment 3

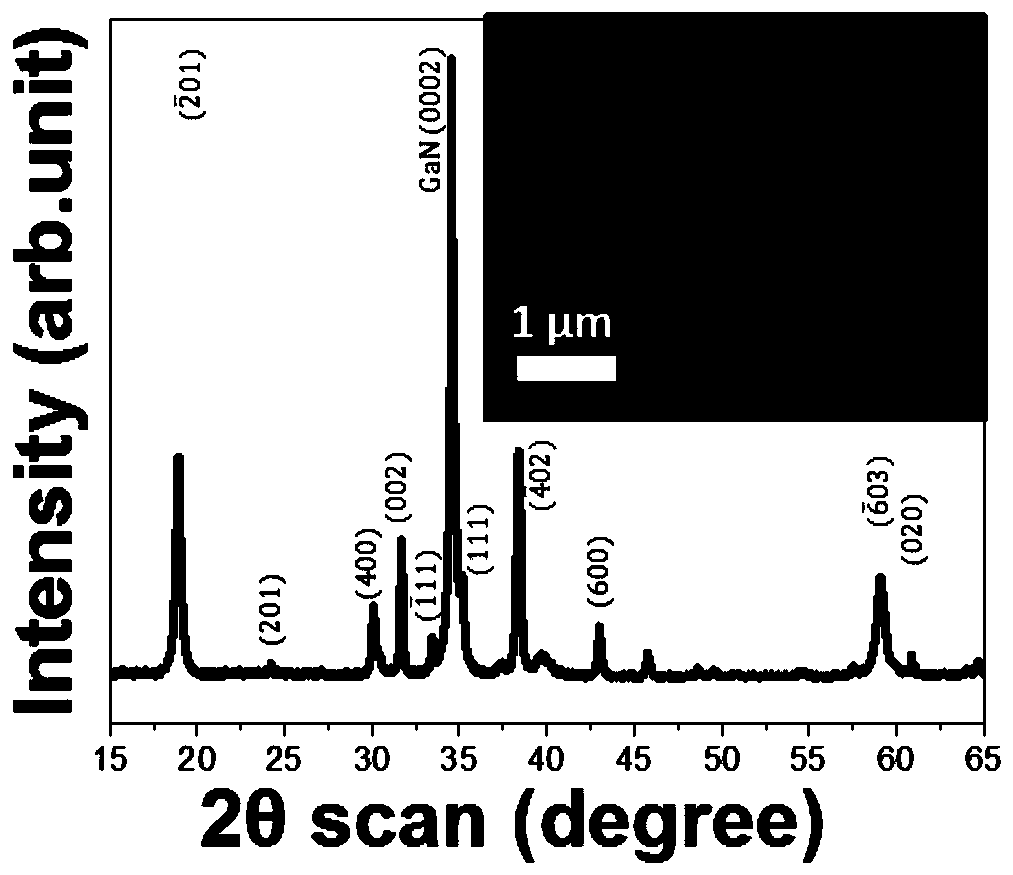

[0079] Embodiment 3: Single crystal β-gallium oxide nanobelt and device.

[0080] (1) A thin layer of platinum is plated on the gallium nitride film:

[0081] Before the gallium oxide nanostructure is grown on the gallium nitride film, a platinum thin layer with a thickness of 8 nm is evaporated on the surface of the gallium nitride.

[0082] (2) Place the gallium nitride film into the chemical vapor deposition equipment, and form platinum particles on the surface of the gallium nitride film by annealing:

[0083] Put the gallium nitride film in step (1) into the CVD chamber, and the pressure in the chamber of the chemical vapor deposition equipment is stabilized at 1.01×10 5 Pa, flow argon gas with a flow rate of 100 sccm, raise the temperature to 500°C, and maintain the temperature for annealing for 60min.

[0084] (3) Annealing in a low-oxygen environment to form gallium nitride nanoseed crystals wrapped with platinum particles on the film:

[0085] Evacuate the air pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com