A kind of preparation method of room temperature self-healing polyurethane elastic fiber

A polyurethane elastic and self-repairing technology, applied in fiber treatment, fiber chemical characteristics, dry spinning method, etc., can solve problems such as polyurethane elastic fiber breakage, achieve the effect of improving sports ability, weakening the degree of microphase separation, and ensuring timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

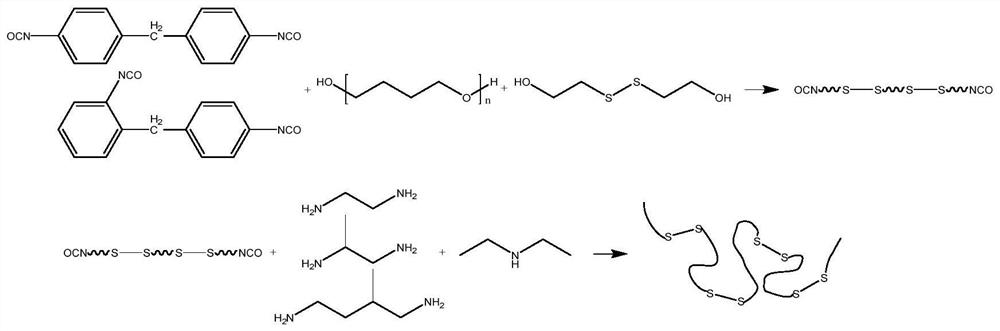

[0034] A kind of preparation method of room temperature self-repairing polyurethane elastic fiber of the present invention comprises the following steps:

[0035] 1. Mix 4,4'-diphenylmethane diisocyanate with 2,4'-diphenylmethane diisocyanate to form a diisocyanate mixture, and mix polytetrahydrofuran ether glycol with 2,2'-dithiodiethanol , to form a dihydric alcohol mixture;

[0036] 2. In the first reactor, add the diisocyanate mixture and the diol mixture at the same time, place it at a temperature of 70-80°C, and fully carry out the prepolymerization reaction to obtain a type A NCO-terminated prepolymer. In the process, N,N-dimethylacetamide is used as a solvent to fully dissolve the Class A NCO-terminated prepolymer to obtain a Class A NCO-terminated prepolymer N,N-dimethylacetamide solution ;

[0037] 3. In the second reactor, the N,N-dimethylacetamide solution of mixed amines of type A is used, wherein the mixed amines of type A include diamines as chain extenders an...

Embodiment 1

[0045] 1. Mix 18.91kg of 4,4'-diphenylmethane diisocyanate with 6.30kg of 2,4'-diphenylmethane diisocyanate to form a diisocyanate mixture. Mix 100.00kg of polytetrahydrofuran ether diol (molecular weight 1800) with 0.95kg2 , 2'-Dithiodiethanol is mixed to form a diol mixture;

[0046] 2. Send 25.21kg of diisocyanate mixture and 100.95kg of diol mixture to the first reactor at the same time. The reaction time is 2.2h and the reaction temperature is 70°C to obtain a type A NCO-terminated prepolymer. In a high-speed dissolver, Using 189.26 kg of N,N-dimethylacetamide as a solvent, fully dissolving the Class A NCO-terminated prepolymer to obtain a Class A NCO-terminated prepolymer N,N-dimethylacetamide solution;

[0047] 3. Mix 315.42kg of Class A NCO-terminated prepolymer N,N-dimethylacetamide solution and 62.78kg of Class A mixed amine N,N-dimethylacetamide solution (including 0.50kg of 1,2-propylenediamine, 2.30kg ethylenediamine, 0.34kg diethylamine) are mixed in the second ...

Embodiment 2

[0055] 1. Mix 21.55kg of 4,4'-diphenylmethane diisocyanate with 7.18kg of 2,4'-diphenylmethane diisocyanate to form a diisocyanate mixture. Mix 100.00kg of polytetrahydrofuran ether diol (molecular weight 1800) with 2.86kg2 , 2'-Dithiodiethanol is mixed to form a diol mixture;

[0056] 2. Send 28.73kg of diisocyanate mixture and 102.86kg of diol mixture to the first reactor at the same time. The reaction time is 2.2h and the reaction temperature is 70°C to obtain a type A NCO-terminated prepolymer. In a high-speed dissolver, Using 197.38kg of N,N-dimethylacetamide as a solvent, fully dissolve the Class A NCO-terminated prepolymer to obtain a Class A NCO-terminated prepolymer N,N-dimethylacetamide solution;

[0057] 3. Mix 328.97kg of NCO-terminated prepolymer N,N-dimethylacetamide solution of type A and 65.38kg of mixed amine N,N-dimethylacetamide solution of type A (including 0.52kg of 1,2-propylenediamine, 2.40kg ethylenediamine, 0.34kg diethylamine) are mixed in the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com