Lateral transistor with AlGaN/GaN heterojunction and production method of lateral transistor

A technology of lateral transistors and heterojunctions, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to improve performance and optimize vertical electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

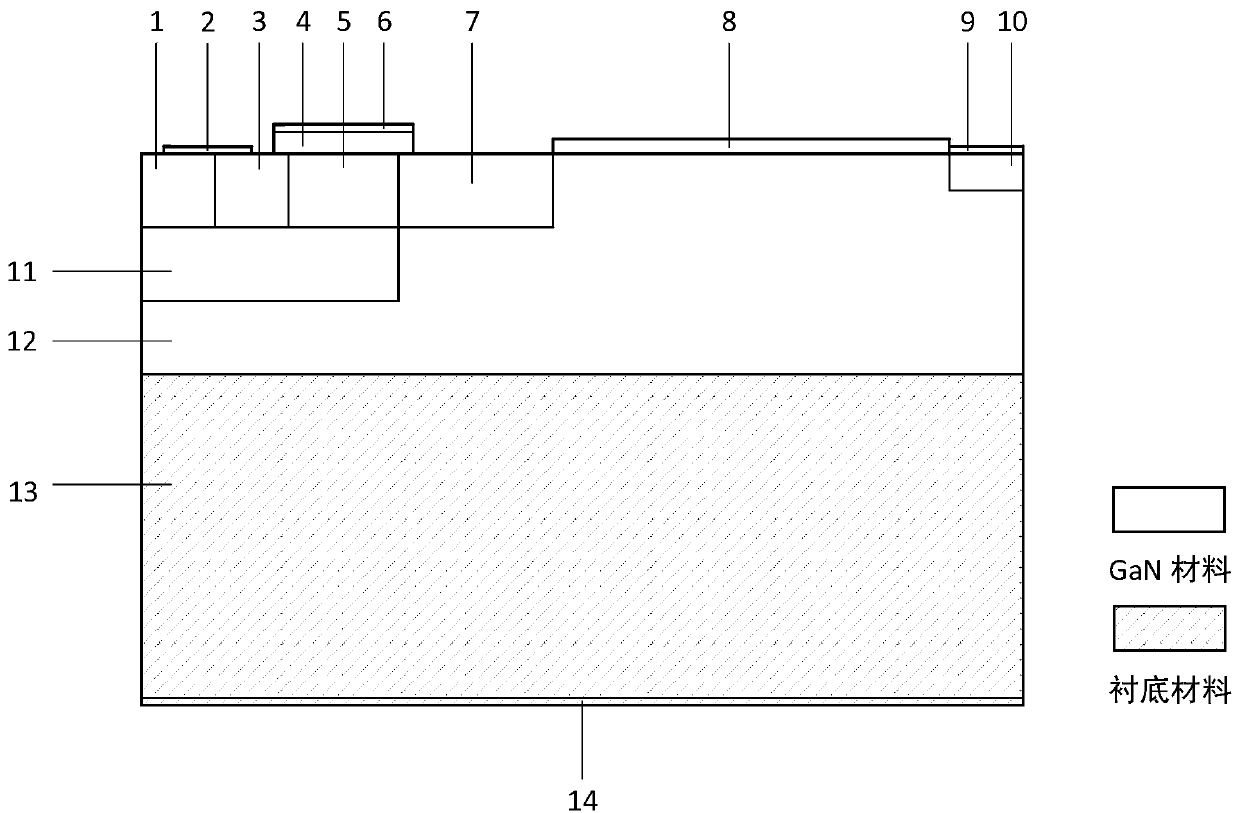

[0037] The present invention will be described below by taking an N-channel lateral transistor with an AlGaN / GaN heterojunction as an example in conjunction with the accompanying drawings.

[0038] Such as figure 1 Shown, the characteristic of the structure of the present embodiment is:

[0039] Base region, source region and channel substrate contact formed by ion implantation based on one end of the GaN epitaxial layer; drain region formed by ion implantation based on the other end of the GaN epitaxial layer; the region of the GaN epitaxial layer close to the base region by ion implantation An N-type drift region is formed by implantation, and the remaining region of the GaN epitaxial layer (between the N-type drift region and the drain region) is formed with an AlGaN layer by heteroepitaxial growth. The length of the AlGaN / GaN heterojunction is 3-3 times the length of the N-type drift region. 10 times; the GaN epitaxial layer under the base region and the source region is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com