Back electrode, solar battery, and preparation methods of back electrode and solar battery

A solar cell and back electrode technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems that it is difficult to make great progress, it is difficult to achieve effective improvement, and it is impossible to achieve large-scale improvement, so as to reduce the area of the dead zone , increase the area, avoid the effect of restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

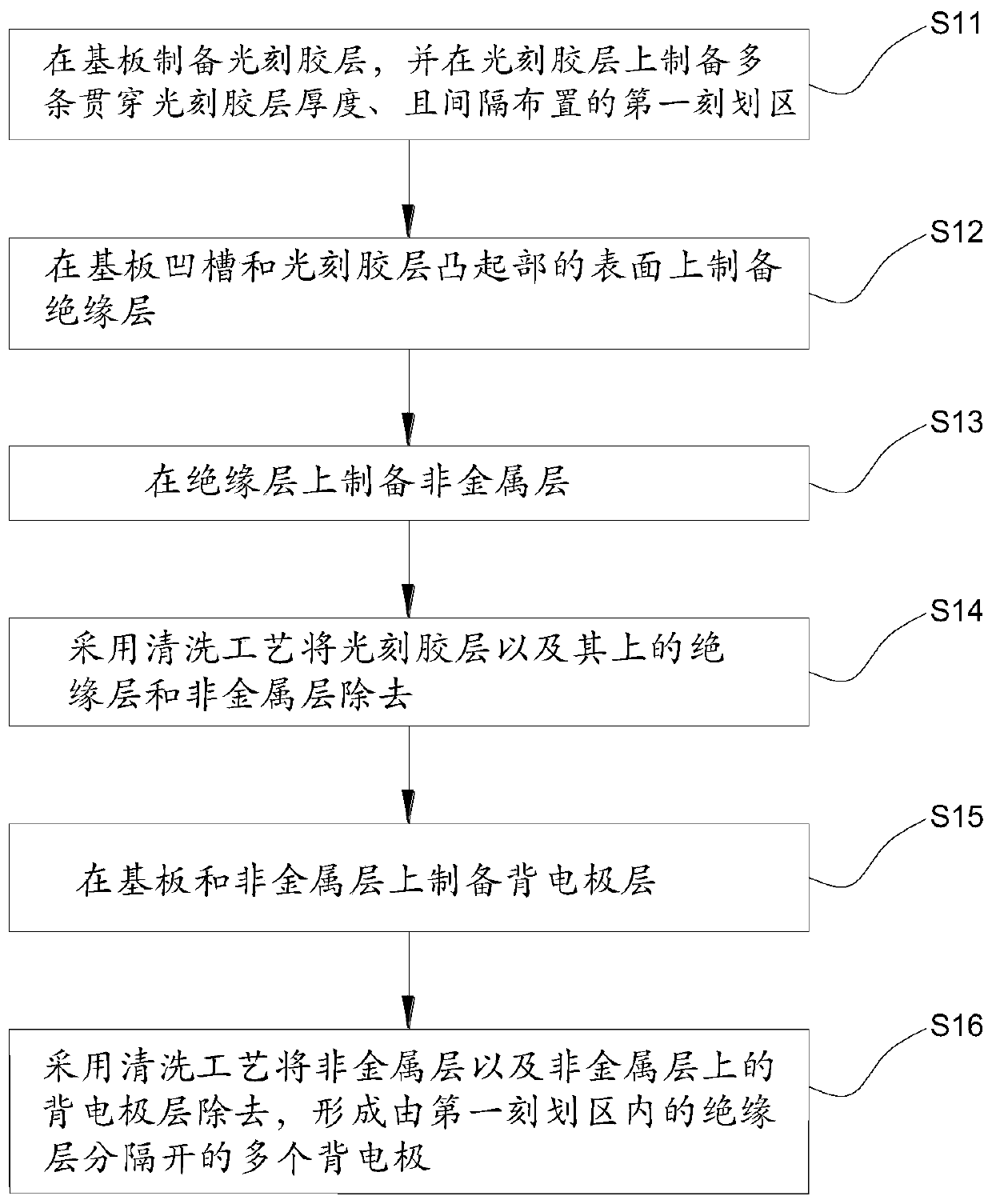

[0052] figure 2 It is the preparation flowchart of solar cell back electrode in the present invention. Such as figure 2 Shown, the preparation method of solar cell back electrode of the present invention comprises the following steps:

[0053] S11 , preparing a photoresist layer 2 on the substrate 1 , and preparing a plurality of first scribed regions penetrating through the thickness of the photoresist layer 2 and arranged at intervals on the photoresist layer 2 . Specifically, the multiple first scoring areas are distributed in an array.

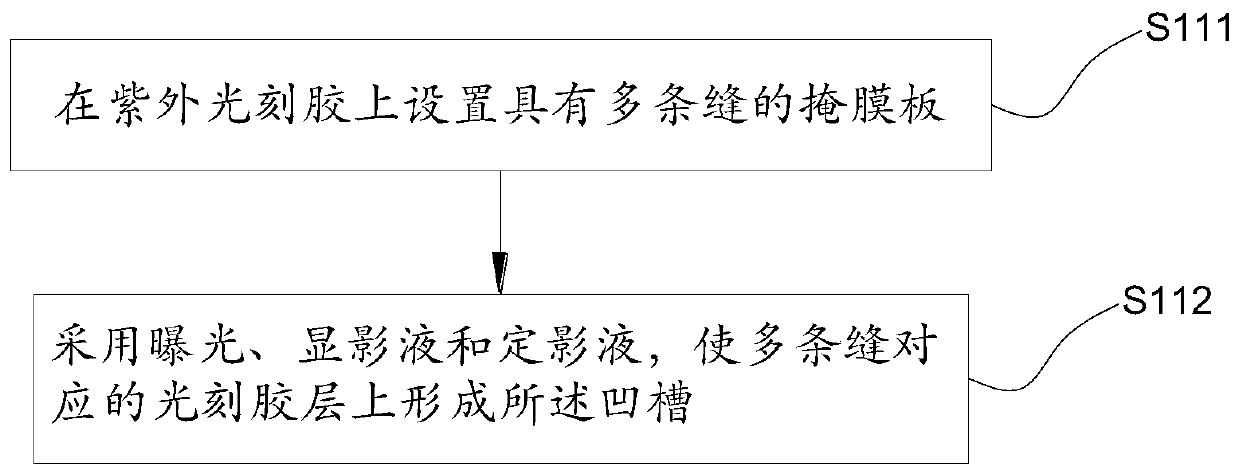

[0054] Such as image 3 As shown, the specific method for preparing the first scribed region on the photoresist layer 2 is as follows:

[0055] S111, setting a mask plate with a plurality of slits on the photoresist;

[0056]S112. Form the first scribed area by means of exposure and development, and obtain the following Figure 4 Structure.

[0057] Specifically, the photoresist can be selected from ultraviolet photoresist. First...

no. 2 approach

[0070] Figure 9 It is a structure diagram corresponding to step S16 of the preparation method provided by the embodiment of the present invention, that is, a schematic diagram of the structure of the back electrode of the solar cell.

[0071] A back electrode of a solar cell, prepared by the method for preparing a back electrode of a solar cell as described in the first embodiment.

no. 3 approach

[0073] Figure 10 Is the preparation flow chart of solar cell in the present invention, as Figure 10 Shown, the preparation method of solar cell of the present invention comprises the following steps:

[0074] S21. Prepare a solar back electrode by using the method as described in the first embodiment.

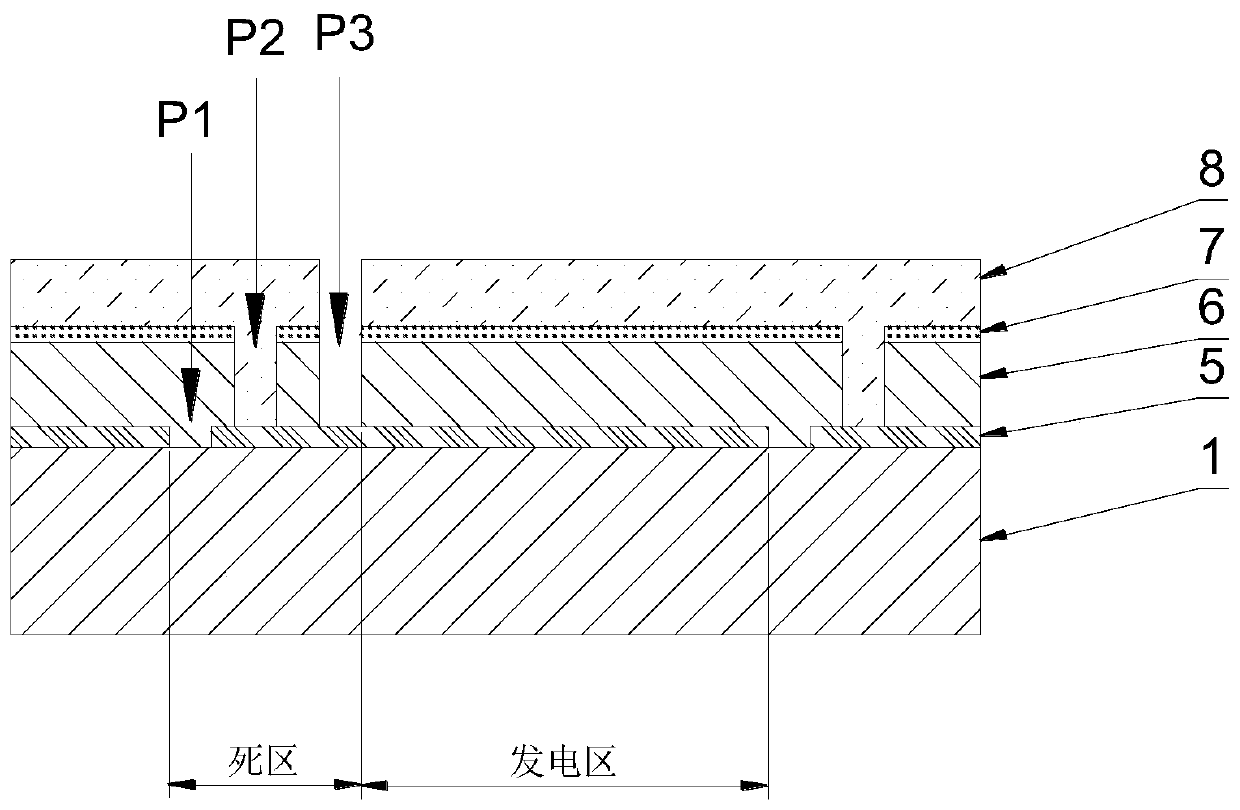

[0075] S22, preparing an absorption layer 6 on the back electrode. Specifically, a copper indium gallium selenide absorption layer is prepared on the above-mentioned back electrode by a co-evaporation method.

[0076] The copper indium gallium selenide absorption layer can also be prepared by sputtering selenization method, spin coating and other methods.

[0077] Copper indium selenide and copper gallium selenide can also be used to prepare the absorbing layer.

[0078] S23. Prepare a cadmium sulfide layer 7 on the absorption layer 6; specifically, prepare the cadmium sulfide layer 7 by using a chemical water bath deposition method. It can also be prepared by vacuum spu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com