Metal-coated spherical cast tungsten carbide powder and preparation method thereof

A technology of casting tungsten carbide and metal cladding, which is applied in the direction of metal material coating process, liquid chemical plating, coating, etc., can solve the problems of high risk factor in operation, insufficient bonding force of coating, and reduced activation effect, etc., to achieve reduction Production cost, ensuring adsorption and chelation effects, and improving the coating binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

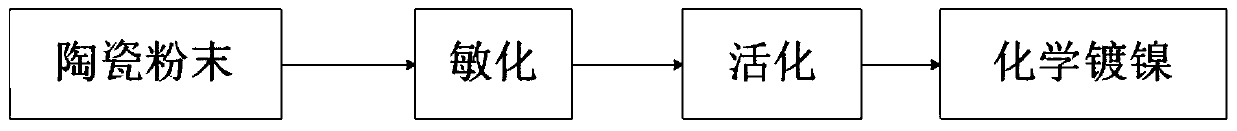

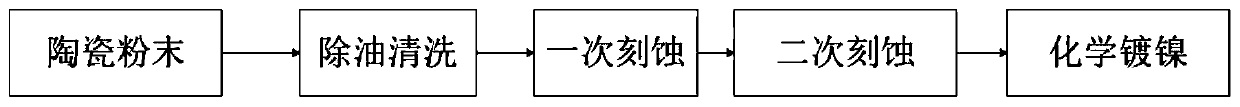

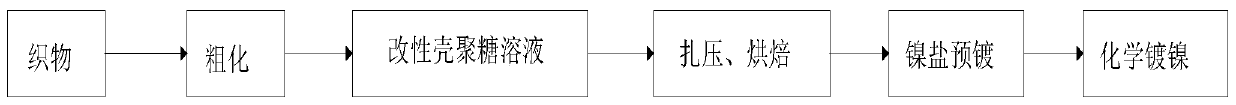

[0044] see Figure 4 , an embodiment of the present invention provides a method for preparing metal-coated spherical cast tungsten carbide powder, which includes:

[0045]Using glutaraldehyde solution to modify chitosan to obtain cross-linked modified chitosan suspension;

[0046] Add spherical cast tungsten carbide to the cross-linked modified chitosan suspension, and then carry out stirring treatment, and take out the modified chitosan / spherical cast tungsten carbide powder obtained after the treatment, and put it into a vacuum drying oven for drying treatment ;

[0047] The modified chitosan / spherical cast tungsten carbide powder after the drying treatment is activated to obtain the activated cast tungsten carbide powder;

[0048] The activated cast tungsten carbide powder is subjected to electroless plating to obtain metal-coated spherical cast tungsten carbide powder.

[0049] In detail, in this example, by modifying chitosan, utilizing chitosan -NH 3 , -OH group to N...

Embodiment 1

[0071] This embodiment provides a metal-coated spherical cast tungsten carbide powder, which is prepared by the following method:

[0072] S1: Weigh 8g of chitosan and add it to 2vol% acetic acid solution, and mechanically stir for 10min to obtain chitosan solution;

[0073] S2: the chitosan solution is added dropwise through a constant pressure funnel into 7ml of a glutaraldehyde solution with a volume fraction of 25vol%, and the stirring is continued for 30min to obtain a cross-linked modified chitosan suspension;

[0074] S3: Weigh 200 g of spherical cast tungsten carbide powder with an average particle size of 70 μm and add it into the cross-linked modified chitosan suspension and stir for 60 min. Take out the treated spherical cast tungsten carbide powder, add it into 20g / L nickel sulfate hexahydrate solution, stir it mechanically for 6h, then add 20ml 40vol% hydrazine hydrate to react for 30min. Then it was washed three times with deionized water, and vacuum-dried to ob...

Embodiment 2

[0079] This embodiment provides a metal-coated spherical cast tungsten carbide powder, which is prepared by the following method:

[0080] S1: Weigh 6g of chitosan and add it to 1vol% acetic acid solution, and mechanically stir for 10 minutes to obtain chitosan solution;

[0081] S2: adding the chitosan solution dropwise through a constant pressure funnel into 5 ml of a glutaraldehyde solution with a volume fraction of 25 vol%, and continuing to stir for 30 min to obtain a cross-linked modified chitosan suspension;

[0082] S3: Weigh 100 g of spherical cast tungsten carbide powder with an average particle size of 56 μm and add it into the cross-linked modified chitosan suspension and stir for 50 min. Then take out the treated spherical cast tungsten carbide powder, add it into 15g / L nickel sulfate hexahydrate solution, stir it mechanically for 5h, then add 15ml 40vol% hydrazine hydrate for 40min reaction. Then it was washed three times with deionized water, and vacuum-dried t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com