Antibacterial and mildew-proof ceramic tile and preparation method thereof

An antibacterial, mildew-proof and ceramic tile technology, which is applied in the field of ceramic processing, can solve the problems of large silver usage, unstable antibacterial performance, and high cost, and achieve strong sterilization and anti-mildew effects, enhanced antibacterial persistence, and excellent bactericidal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

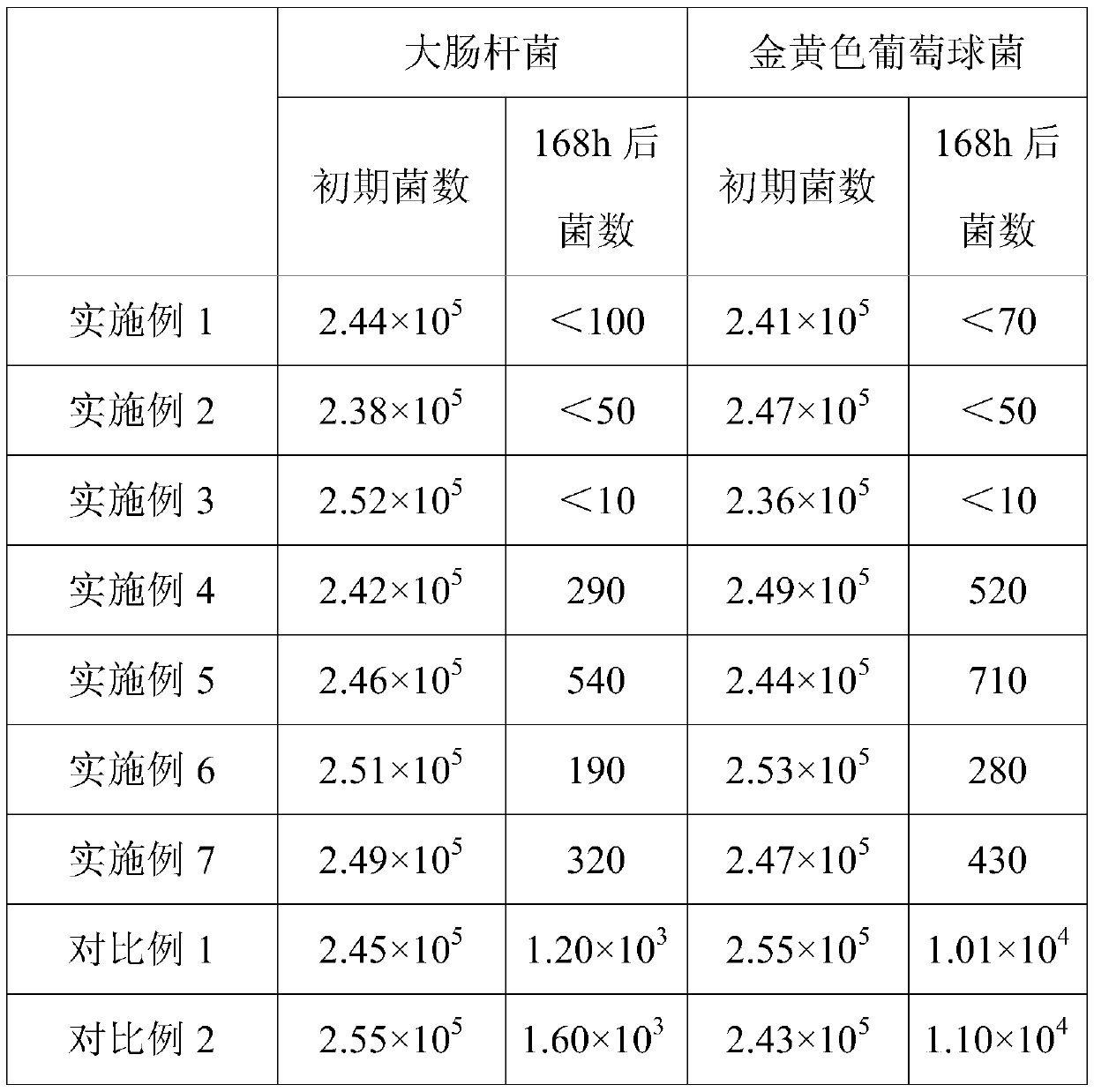

Examples

Embodiment 1

[0064] This embodiment provides an antibacterial and antifungal ceramic tile and a preparation method thereof. The antibacterial antifungal ceramic tile includes a blank material, a glaze, and an antibacterial agent;

[0065] Wherein, the composition of the blank material includes 26.6 parts by weight of kaolin, 12.7 parts of feldspar, 12.5 parts of burnt talc, 22.4 parts of ceramic tile waste, 2.2 parts of diatomaceous earth, and 23.6 parts of quartz;

[0066] The composition of the glaze includes 30.7 parts by weight of potassium feldspar, 34.8 parts of calcium carbonate, 29.6 parts of barium carbonate, 4.1 parts of silver oxide and 0.8 parts of terbium oxide, and the mass percentage of the glaze to the body material is 16 wt. %;

[0067] The antibacterial agent includes nano zinc oxide and silica sol, the mass percentage of nano zinc oxide is 37.6 wt%, and the mass percentage of the antibacterial agent in the glaze is 21 wt%.

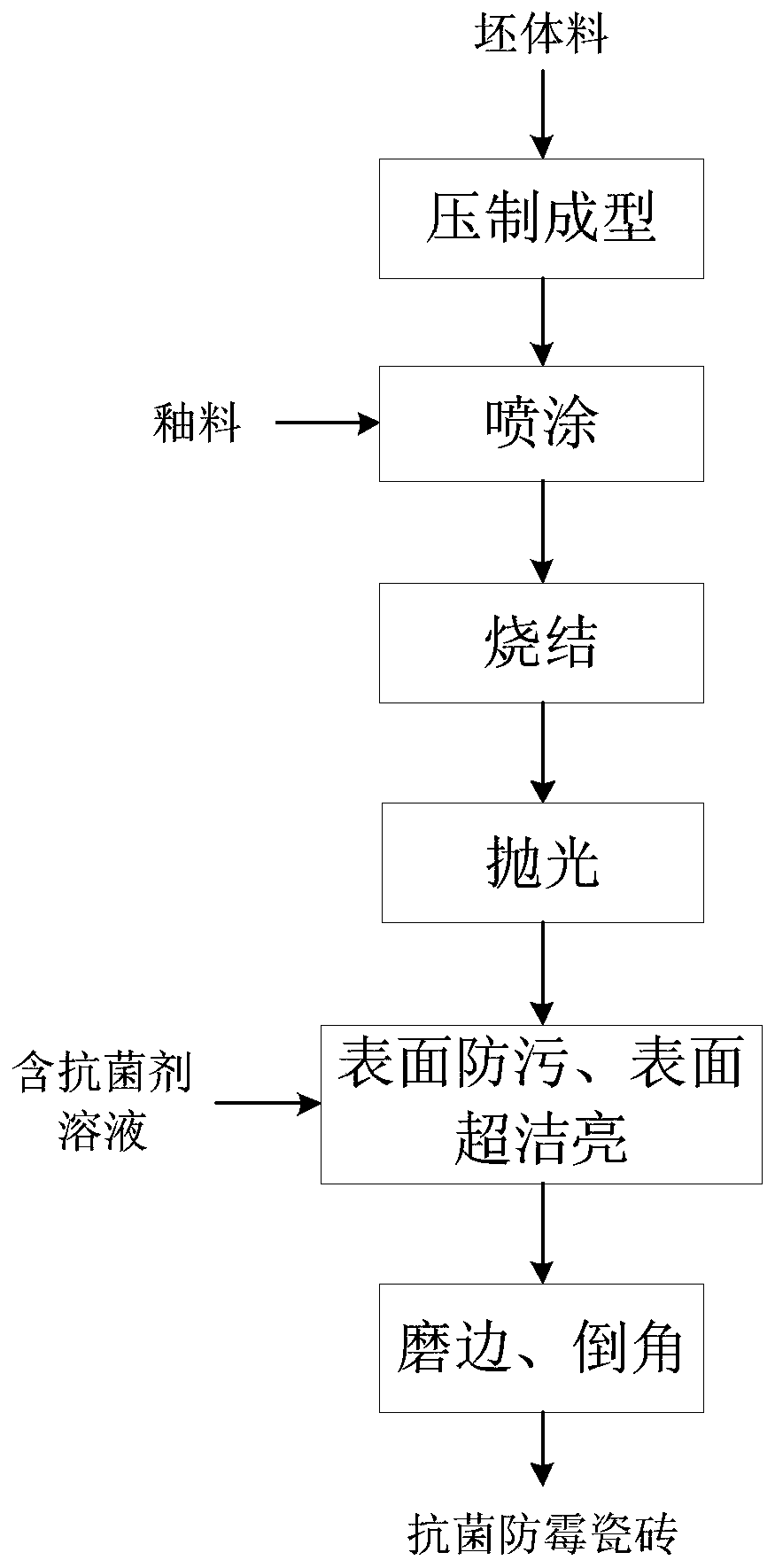

[0068] The process flow diagram of the method is as fi...

Embodiment 2

[0073] This embodiment provides an antibacterial and antifungal ceramic tile and a preparation method thereof. The antibacterial antifungal ceramic tile includes a blank material, a glaze, and an antibacterial agent;

[0074] Wherein, the composition of the blank material includes 35.4 parts by weight of kaolin, 11.2 parts of feldspar, 14.3 parts of burnt talc, 15.7 parts of ceramic tile waste, 3.5 parts of diatomaceous earth, and 19.9 parts of quartz;

[0075] The composition of the glaze includes 39.4 parts by weight of potassium feldspar, 20.4 parts of calcium carbonate, 35.3 parts of barium carbonate, 3.7 parts of silver oxide, and 1.2 parts of terbium oxide. The mass percentage of the glaze in the body material is 15 wt. %;

[0076] The antibacterial agent includes nano zinc oxide and silica sol, the mass percentage of nano zinc oxide is 44.2 wt%, and the mass percentage of the antibacterial agent accounts for 24 wt% of the glaze.

[0077] The method includes the following steps:...

Embodiment 3

[0082] This embodiment provides an antibacterial and antifungal ceramic tile and a preparation method thereof. The antibacterial antifungal ceramic tile includes a blank material, a glaze, and an antibacterial agent;

[0083] Wherein, the composition of the blank material includes 12.0 parts by weight of kaolin, 18.7 parts of feldspar, 19.7 parts of burnt talc, 17.1 parts of ceramic tile waste, 5.7 parts of diatomaceous earth, and 21.8 parts of quartz;

[0084] The composition of the glaze includes 35.5 parts by weight of potash feldspar, 30.6 parts of calcium carbonate, 27.1 parts of barium carbonate, 5.3 parts of silver oxide, and 1.5 parts of terbium oxide. The mass percentage of the glaze in the body is 13 wt. %;

[0085] The antibacterial agent includes nano zinc oxide and silica sol, the mass percentage of nano zinc oxide is 51.1 wt%, and the mass percentage of the antibacterial agent accounts for 28 wt% of the glaze.

[0086] The method includes the following steps:

[0087] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com