Application of artemisinin in preparation of drugs to treat c-myc/mTOR-activated human hepatoma SMMC7721 cells

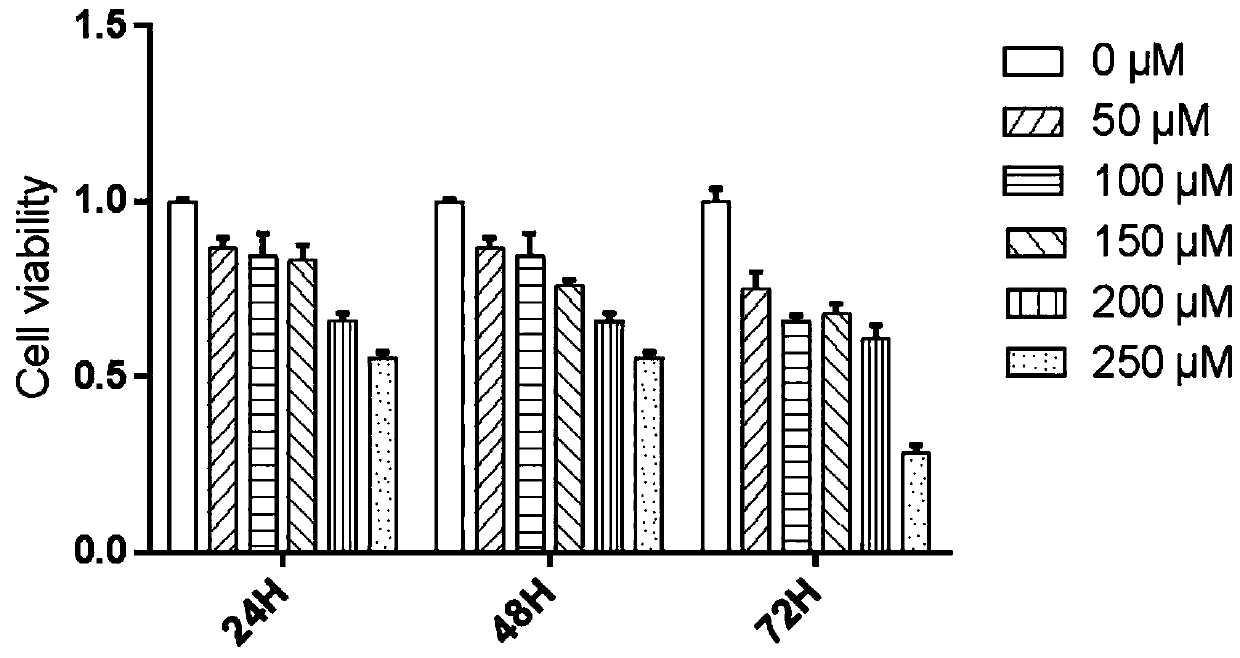

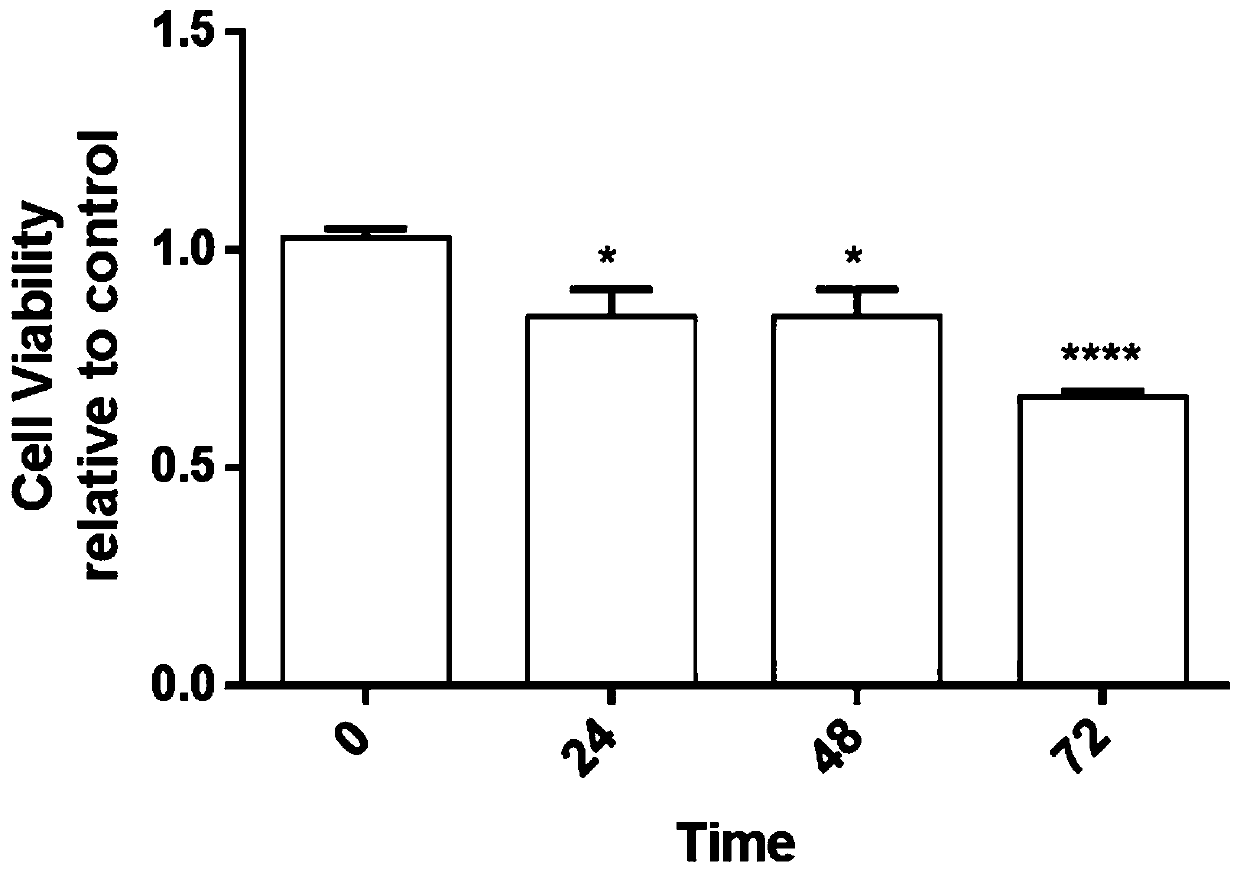

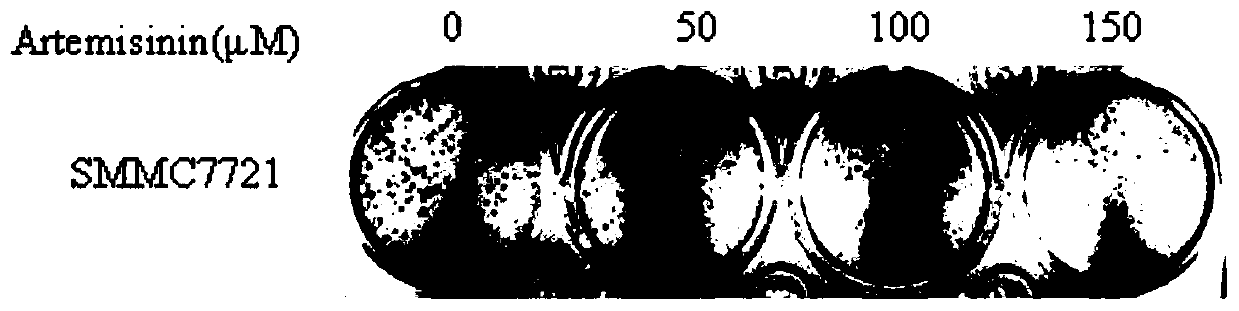

A technology of p-c-myc and artemisinin, which is applied in the field of medicine and achieves good time- and concentration-dependent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The artemisinin medicine is made into a suppository, and the preparation method is as follows:

[0033] 1) Add 203.7g polyethylene glycol 4000, 101.8g polyethylene glycol 400, 33.9g purified water, 4g Tween-80, and melt at 80°C; 2) Add 50g artemisinin under constant stirring, and then add 4g Vitamin E, stir for 30 minutes to make it uniform; 3) Add the prepared solution into the storage medicine tank of the BZS-1 suppository filling and sealing unit, set the heat preservation temperature to 54°C, start the filling unit, and the filling speed is 3000 capsules per hour to obtain artemisinin suppositories.

[0034] Administration method:

[0035] Common dosage for adults: rectal administration, 0.6g for the first time, 0.6g after 4 hours, 0.4g each on the second and third day.

[0036] Precautions: 1. If you defecate within 2 hours after the anal plug, you should reapply it once.

Embodiment 2

[0038] The artemisinin drug is made into microcapsule particles, and the preparation method is as follows:

[0039] 1) Pass 1-10 mg of artemisinin through a 100-mesh sieve, and dissolve it in ethanol 7 times its weight; 2) Add 20 mg of sodium starch phosphate and 50 mg of Tween emulsifier, and stir evenly to obtain a core material solution; 3) With 10mg of chitosan, 20mg of carboxymethyl chitosan octadecyl quaternary ammonium salt and 50mg of gelatin are used as the wall material, water 7 times the weight of the wall material is added, the temperature is raised to 55°C, and the mixture is evenly stirred to obtain a wall material suspension; 4) Homogenize the above-mentioned core material solution and wall material suspension in a latex ultrasonic homogenizer for 25 minutes according to the weight ratio of 1:4 to obtain an emulsion; 5) Transport the emulsion obtained in step 4) to the granulation spray machine for spray drying, cooled to room temperature, and packaged to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com