Schottky diode and preparation method thereof

A Schottky diode and electrode technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as high cost, high technical difficulty, and inability to Schottky diodes, and achieve improved stability and low turn-on Voltage, effect of high reverse breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

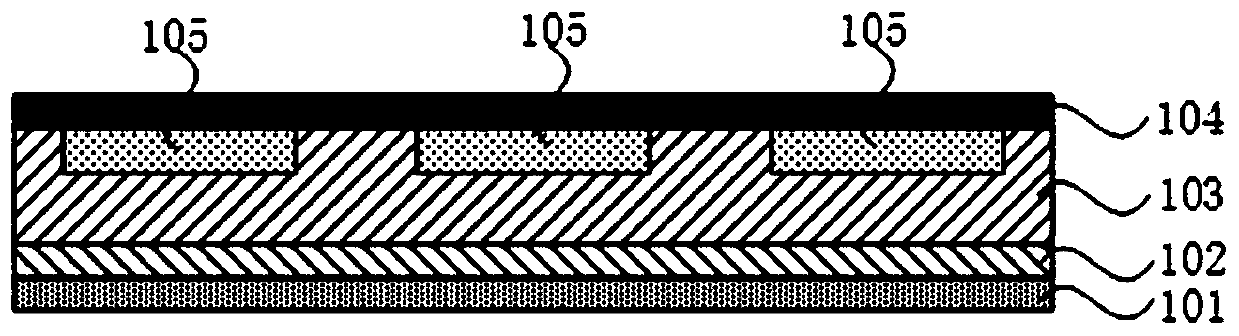

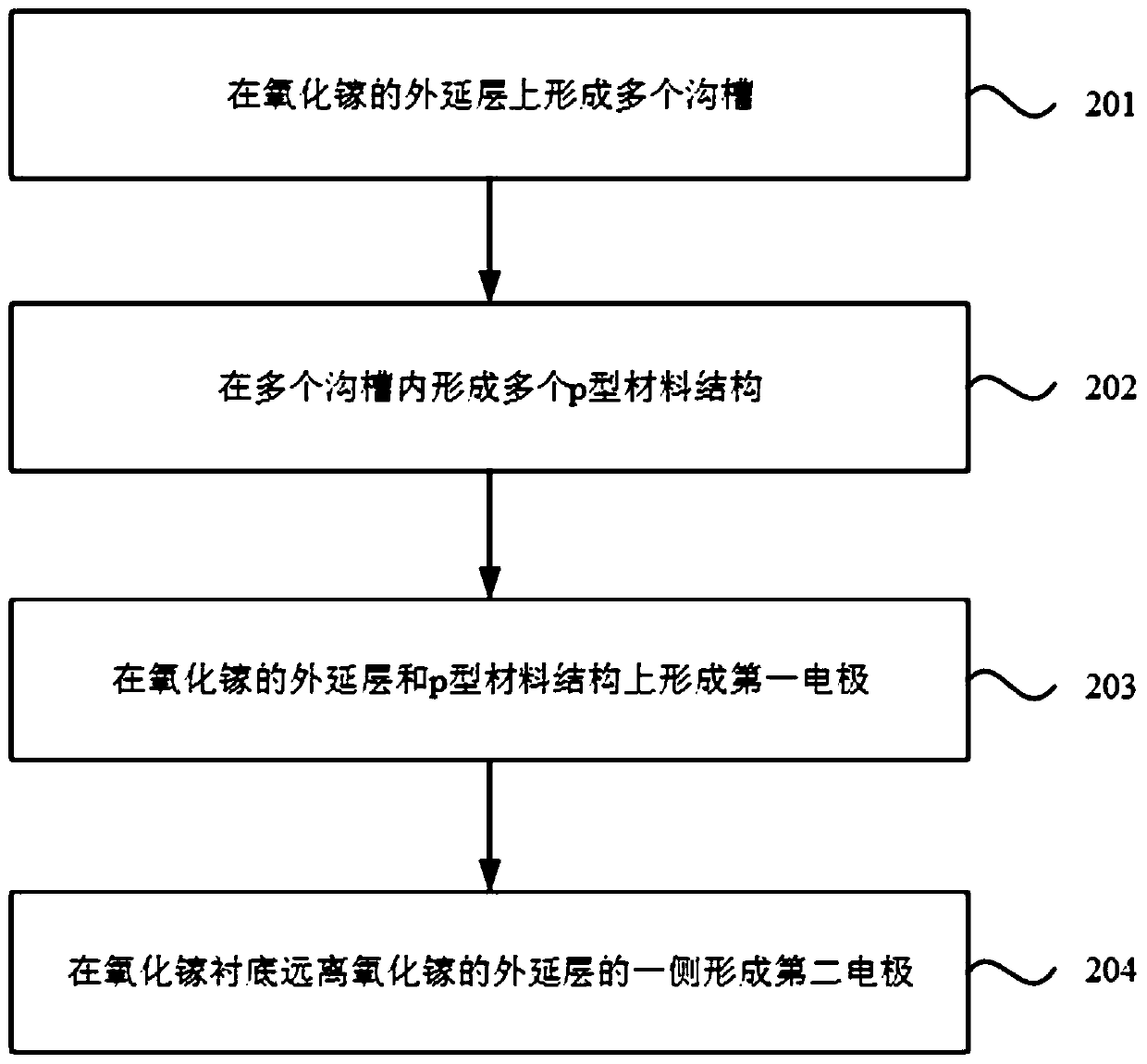

[0037] refer to figure 1 , figure 1 A schematic structural diagram of a Schottky diode provided by an embodiment of the present invention, the Schottky diode includes a gallium oxide substrate 102;

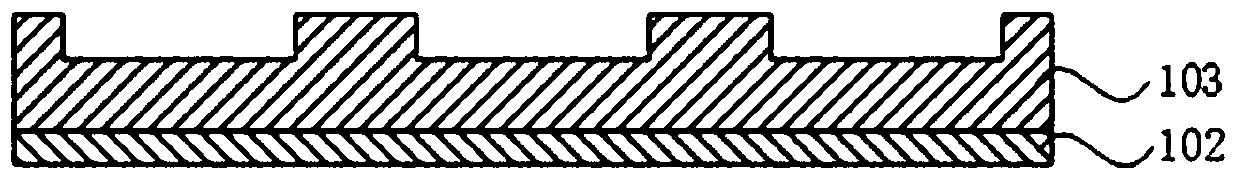

[0038] a gallium oxide epitaxial layer 103 on a gallium oxide substrate 102, wherein a plurality of grooves are provided on a side of the gallium oxide epitaxial layer 103 away from the gallium oxide substrate 102;

[0039] a p-type material structure 105 located in the plurality of trenches;

[0040] a first electrode 104 covering the p-type material structure 105 and the gallium oxide epitaxial layer 103;

[0041] The second electrode 101 is located on the side of the gallium oxide substrate 102 away from the gallium oxide epitaxial layer 103 .

[0042] Specifically, the gallium oxide substrate 102 is n-type highly doped (n+) gallium oxide, and the gallium oxide epitaxial layer 103 is n-type low-doped (n-); the gap between the second electrode 101 and the gallium oxide substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com