Lithium sulfur battery positive electrode material and preparation method thereof

A technology for lithium-sulfur batteries and cathode materials, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve problems affecting practical applications, achieve low cost, simple preparation process, and improve long-term cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

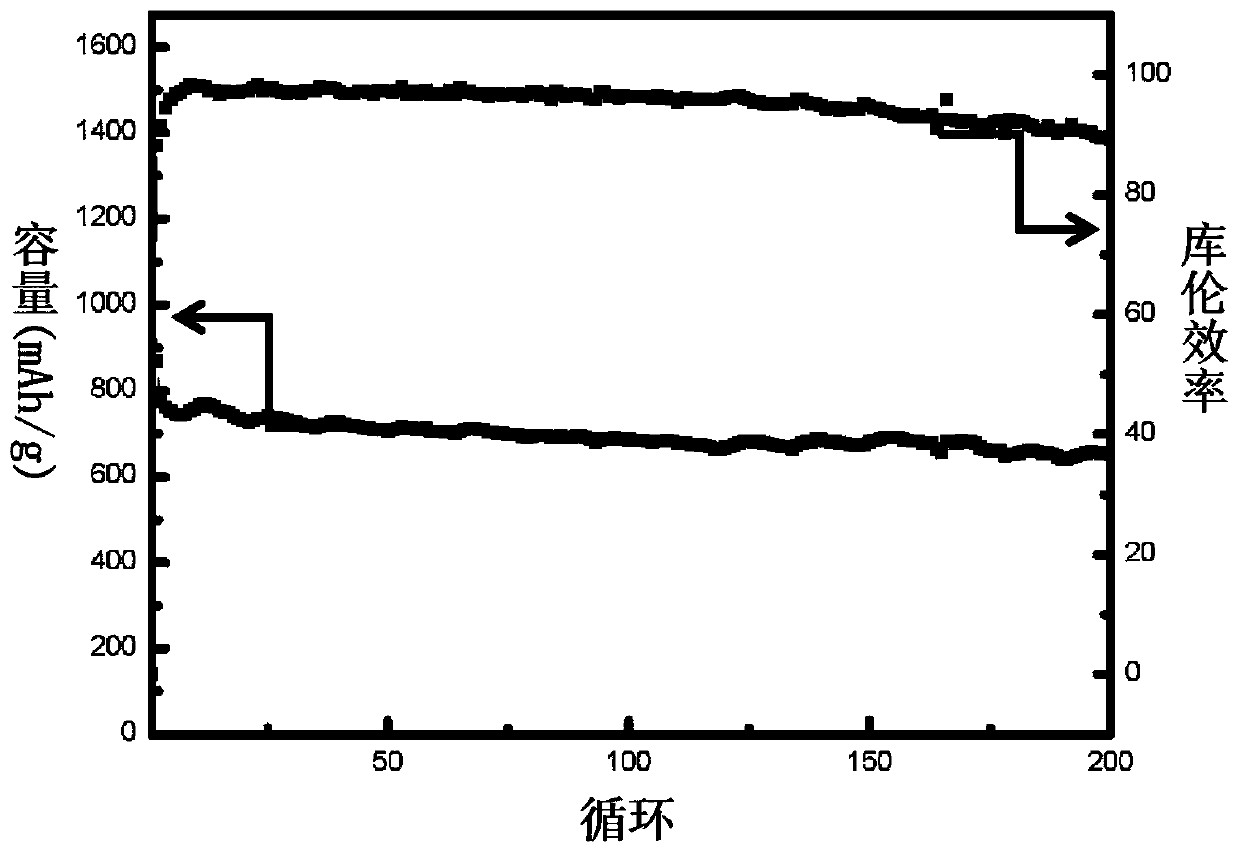

Embodiment 1

[0059] Take 0.16 g of cetyltrimethylammonium bromide and put it into 50ml of deionized water and fully stir for 0.6 hours to prepare the reaction mother liquor. Place the prepared reaction mother liquor in a thermostat at 80°C for 24 hours and then take out the reaction mother liquor. , And add ethyl orthosilicate to it, the ratio of the ethyl orthosilicate to mother liquor is: 0.3 g of reaction mother liquor is added per 1ml of ethyl orthosilicate, magnetically stirred at room temperature for 5 hours, and the reaction is sealed after After 24 hours, after the reaction is over, the resulting reactant is suction filtered, and washed alternately with absolute ethanol and deionized water for at least three times to a paste; the paste product is dispersed in 80ml of deionized water, and magnetically stirred for 2 hours; a nanometer is formed The silica mesoporous sphere dispersion liquid has a concentration of 0.1 mg / ml.

[0060] Weigh 0.4g of gelatin in 100ml of absolute ethanol, di...

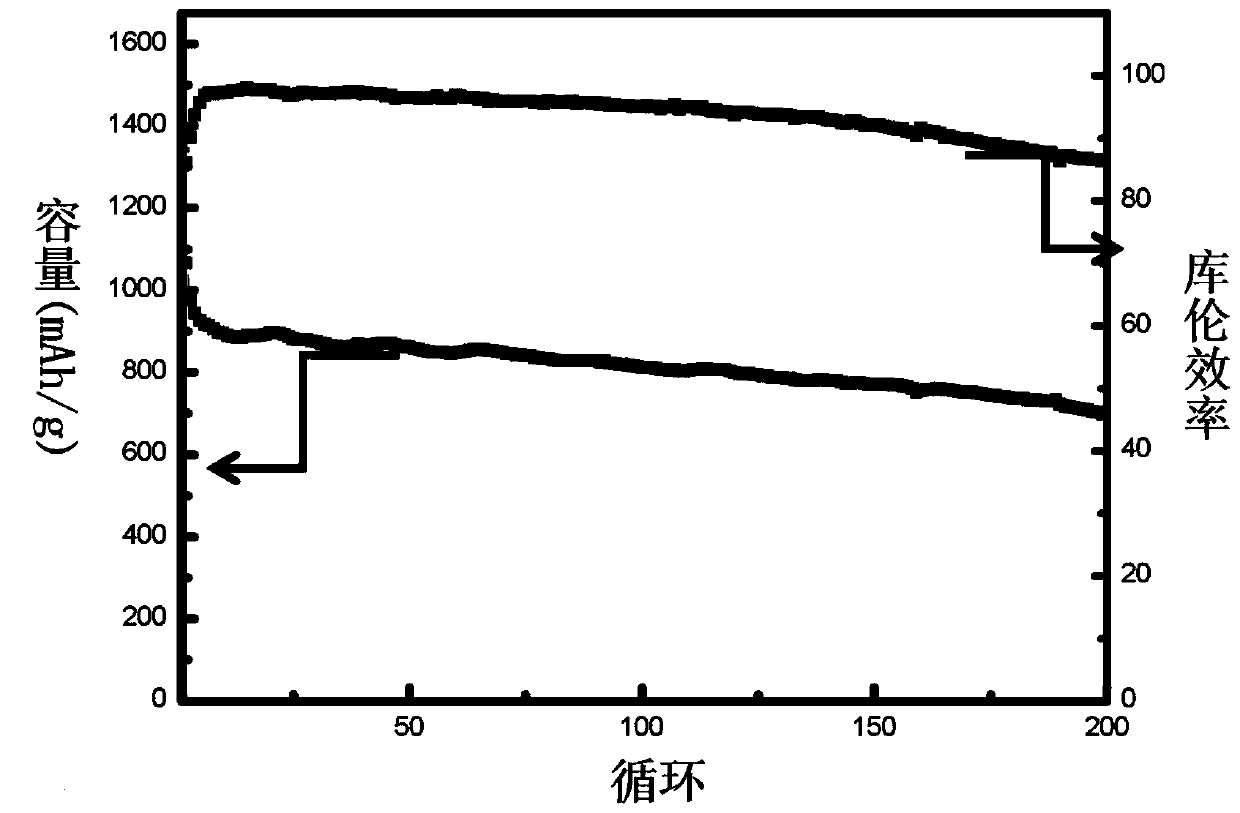

Embodiment 2

[0064] Take 0.1 g of cetyltrimethylammonium bromide and put it into 50ml of deionized water and stir for 0.6 hours to prepare the reaction mother liquor. Place the prepared reaction mother liquor in a thermostat at 60°C for 48 hours; take out the reaction mother liquor, Ethyl orthosilicate was added to it. The ratio of the ethyl orthosilicate to the reaction mother liquor was 0.08g per 1ml of ethyl orthosilicate, stirred magnetically for 1 hour at room temperature, and reacted for 10 hours after sealing. After the reaction, the reactant is generated; the reactant is suction filtered, washed alternately with absolute ethanol and deionized water for at least three times until it becomes a paste; the paste product is dispersed in 50ml of deionized water and magnetically stirred for 2 hours; a nanometer is formed Silica mesoporous sphere dispersion; its concentration is 10mg / ml.

[0065] Weigh 0.4g glucose in 100ml absolute ethanol and pour it into the nano-silica mesoporous sphere d...

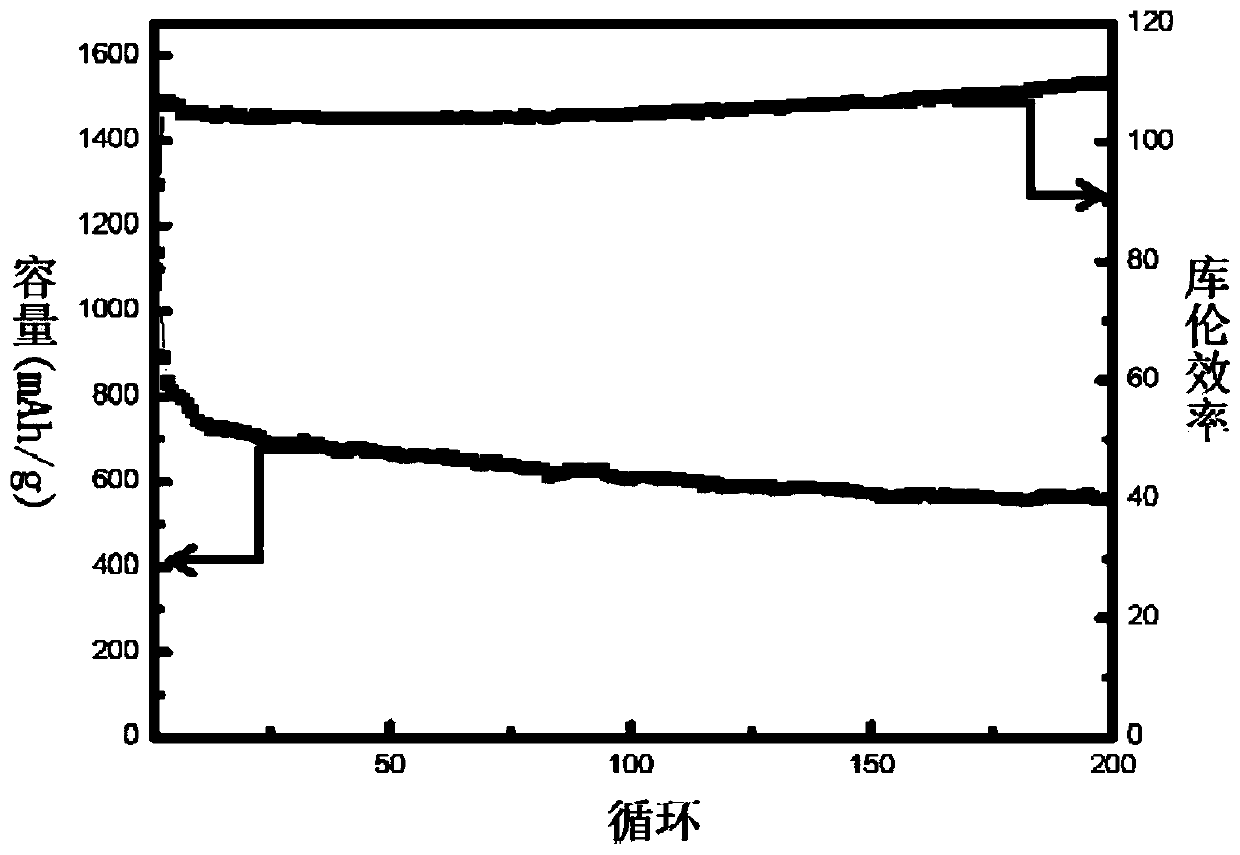

Embodiment 3

[0069] Take 0.25 g of cetyltrimethylammonium bromide into 50 ml of deionized water and stir for 0.6 hours to prepare the reaction mother liquor. The prepared reaction mother liquor is placed in a thermostat at 90°C for 30 hours; the reaction mother liquor is taken out, And add ethyl orthosilicate to it, the ratio of the ethyl orthosilicate to the reaction mother liquor is: 0.64 g of the reaction mother liquor is added per 1ml of ethyl orthosilicate, magnetically stirred at room temperature for 10 hours, and after sealing After reaction for 38 hours, reactants are formed after the reaction is completed; the reactants are suction filtered, washed alternately with absolute ethanol and deionized water for at least three times to a paste; the paste is dispersed into 150ml of deionized water, and magnetically stirred for 2 hours ; The formation of nano-silica mesoporous sphere dispersion. Its concentration is 8mg / ml.

[0070] Weigh 0.4 g of glucose in 100 ml of absolute ethanol and po...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap