Macroporous iron oxide and synthesis process method thereof

A synthesis process, iron oxide technology, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of uneven pore distribution of materials, long time-consuming template assembly, difficult industrial production, etc., to achieve uniform properties and low production costs Low, highly reproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

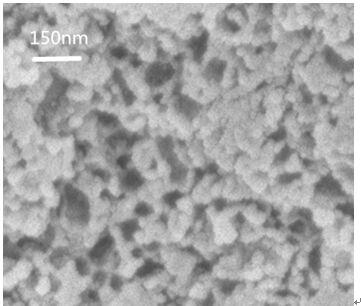

Image

Examples

Embodiment 1

[0047] (1) Dissolve 0.4 g of sodium hydroxide in 25 mL of 25 wt% TEAOH and 10 mL of distilled water, and stir for 30 min. Then add 0.7 g of sodium aluminate and stir for 30 min. Add 12 g of white carbon black slowly and stir for 30 min. Then put it into a closed reactor and crystallize in an oven at 120°C for 30 h. Then the obtained product was washed with distilled water until neutral, and then dried at 120° C. for 12 hours to obtain a Beta molecular sieve.

[0048] (2) Put the Beta molecular sieve obtained in step (1) into 50 mL of 50wt% propylene glycol solution and allow it to settle naturally. When the molecular sieve has just settled to the bottom, take out 1 / 3 of the solution in the middle of the entire solution and filter it. Dry at 120°C for 10h.

[0049] (3) Mix the Beta molecular sieve obtained in step (2) with 5mL of 0.45moL / L hydrochloric acid, put it into a closed reactor and treat it at 110°C for 5h, then wash the obtained product with distilled water until i...

Embodiment 2

[0056] (1) Dissolve 0.29 g of sodium hydroxide in 40 mL of 25 wt% TEAOH and 20 mL of distilled water, and stir for 30 min. Then add 0.7 g of sodium aluminate and stir for 30 min. Add 16.5 g of white carbon black slowly and stir for 30 min. Then put it into a closed reactor and crystallize in an oven at 160°C for 20 h. Then the obtained product was washed with distilled water until neutral, and then dried at 120° C. for 12 hours to obtain a Beta molecular sieve.

[0057] (2) Put the Beta molecular sieve obtained in step (1) into 780 mL of 70wt% glycerol solution and let it settle naturally. Filter and dry at 120°C for 10h.

[0058] (3) Mix the Beta molecular sieve obtained in step (2) with 15mL of 1moL / L hydrochloric acid, put it into a closed reactor at 70°C for 8 hours, then wash the obtained product with distilled water until it is neutral, and then put it under the condition of 120°C Dry for 12 hours.

[0059] (4) Mix the Beta molecular sieve obtained in step (3) with ...

Embodiment 3

[0065] (1) Dissolve 0.8 g of sodium hydroxide in 43 mL of 25 wt% TEAOH and 10 mL of distilled water, and stir for 30 min. Then add 1.02 g of sodium aluminate and stir for 30 min. Add 12 g of white carbon black slowly and stir for 30 min. Then put it into a closed reactor and crystallize in an oven at 105°C for 50 h. Then the obtained product was washed with distilled water until neutral, and then dried at 120° C. for 12 hours to obtain a Beta molecular sieve.

[0066] (2) Put the Beta molecular sieve obtained in step (1) into 20 mL of 13wt% propylene glycol solution, and let it settle naturally. When the molecular sieve has just settled to the bottom, take out 1 / 7 of the solution in the middle of the entire solution, and filter it. Dry at 120°C for 10h.

[0067] (3) Mix the Beta molecular sieve obtained in step (2) with 5mL of 0.1moL / L hydrochloric acid, put it in a closed reactor and treat it at 183°C for 2h, then wash the obtained product with distilled water until it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com