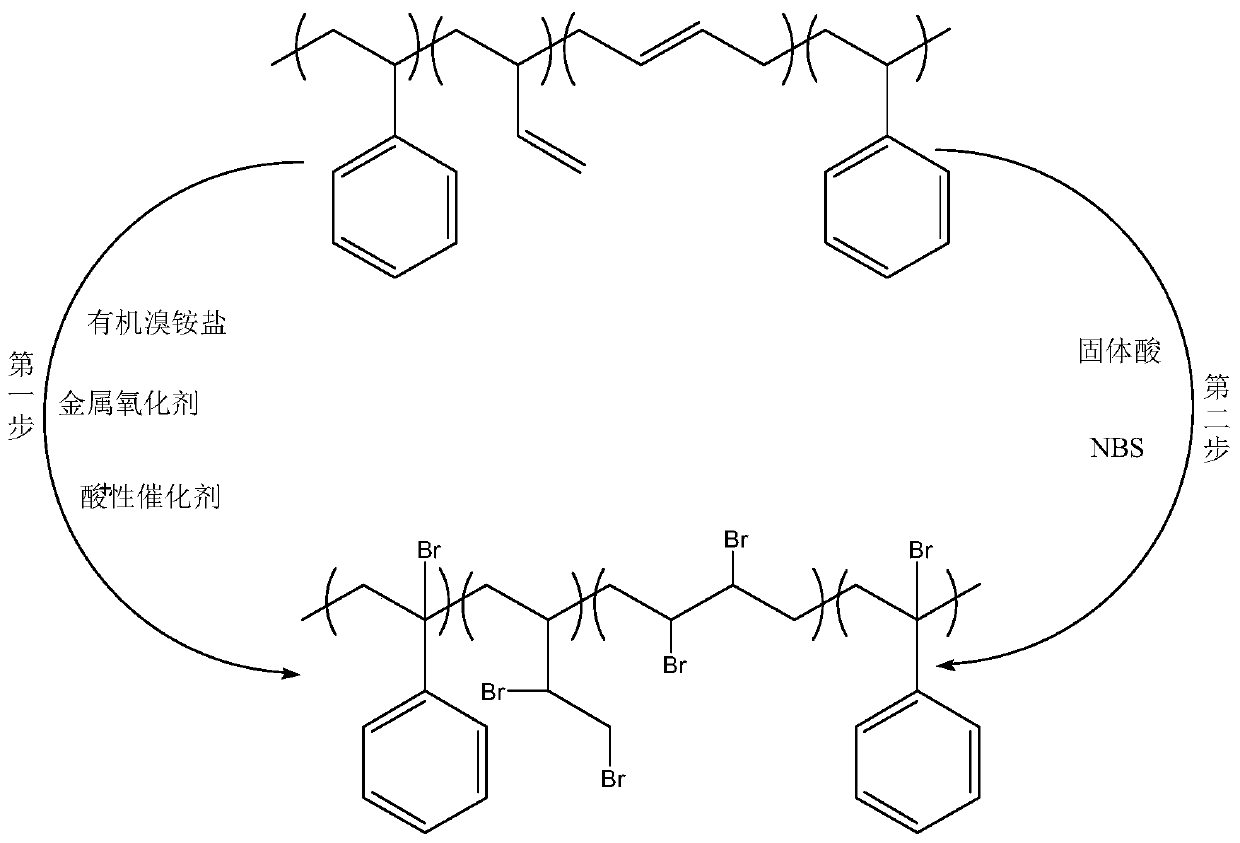

Method for preparing brominated styrene-butadiene copolymer through heterogeneous oxidation

A technology of brominated styrene and heterogeneous oxidation, which is applied in the production of bulk chemicals, etc., can solve the problems of failing to meet the requirements of flame retardant properties of building materials products, poor flame retardant effect of halogen-free flame retardants, and halogen-free flame retardants. The problem of low flame retardant efficiency of the flame retardant, to achieve the effect of high bromine content, easy to control, and ensure the formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

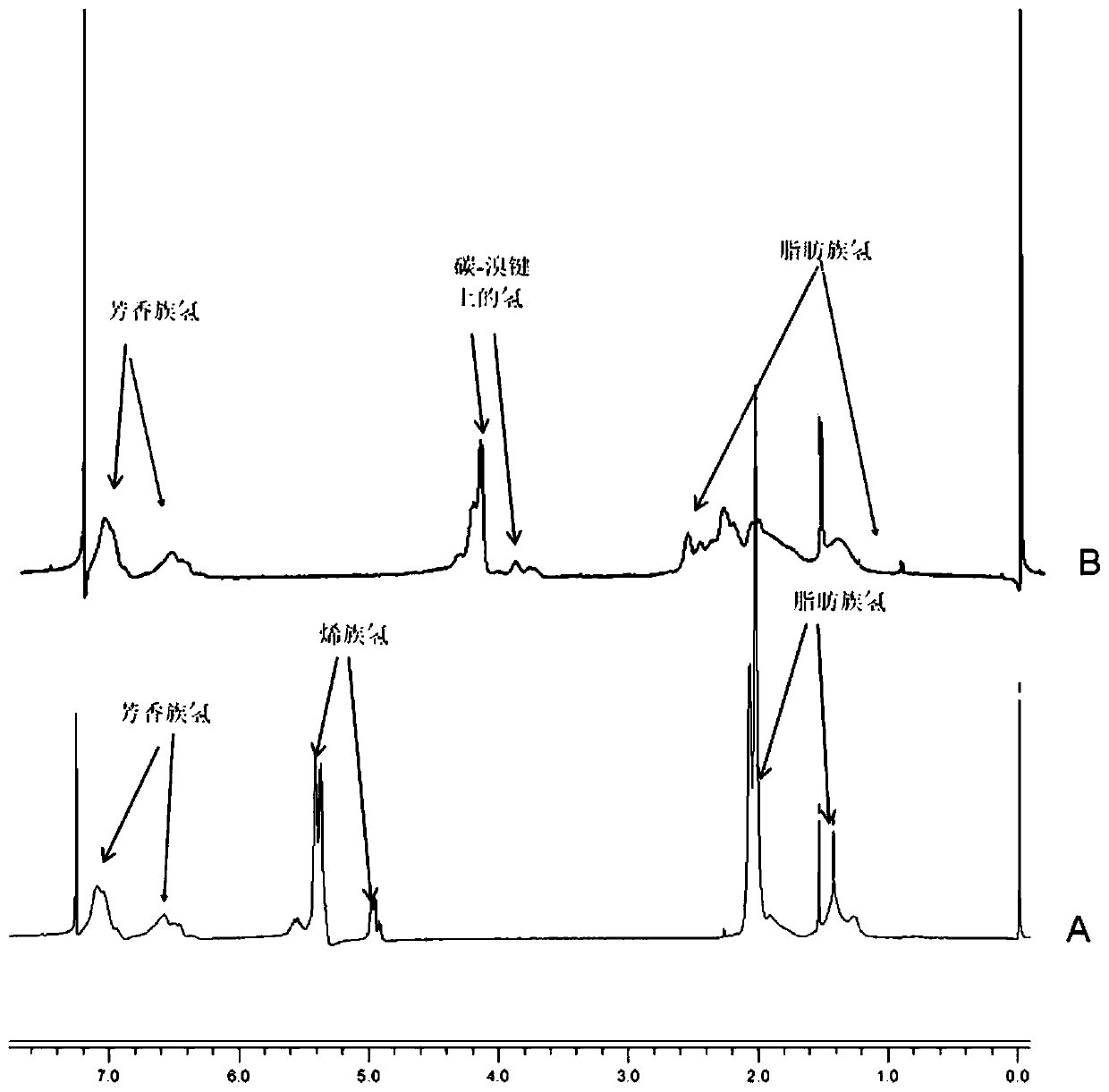

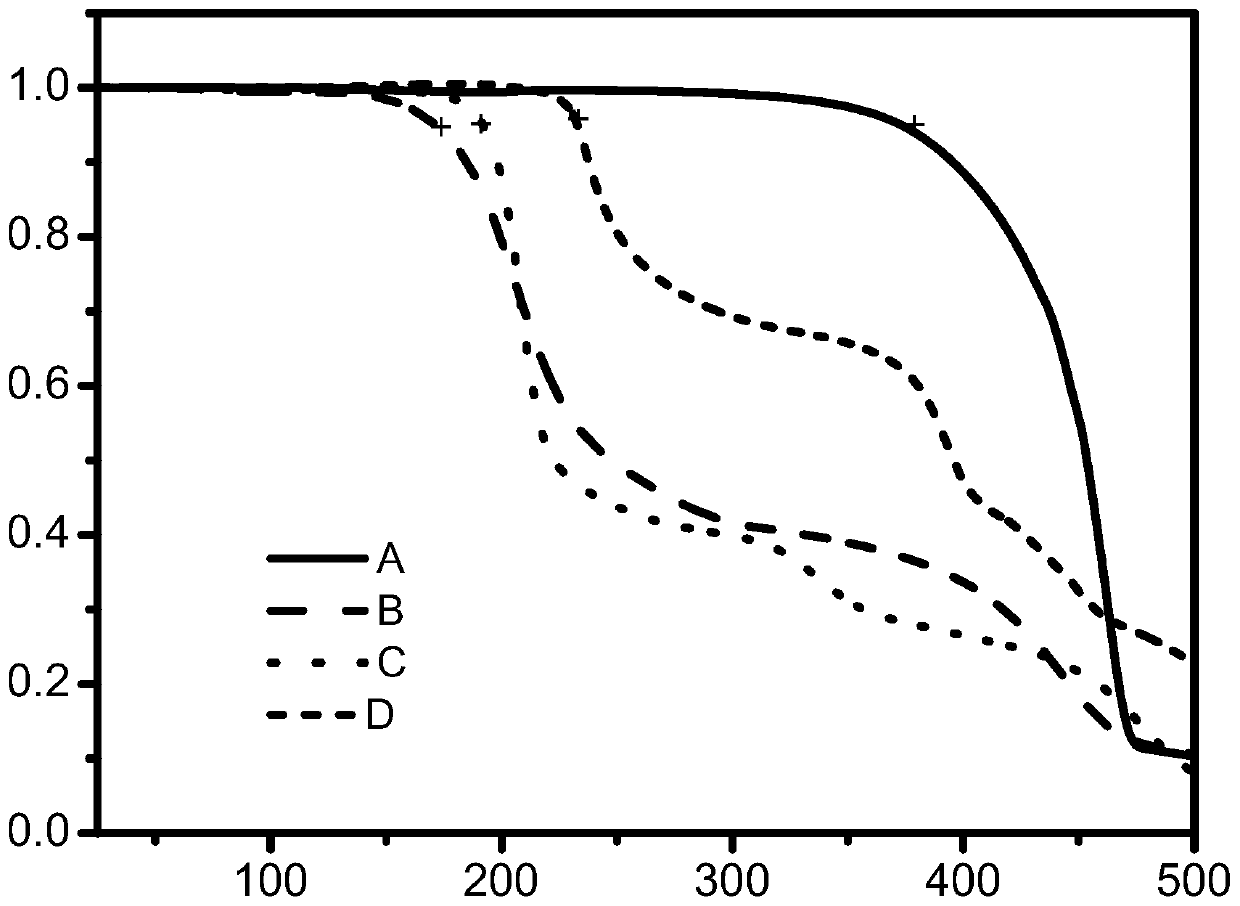

Method used

Image

Examples

Embodiment 1

[0035] (1) Dissolve 10g SBS with 70ml organic solvent chloroform, add 180g 45% tetraethylammonium bromide aqueous solution, be warming up to 25 ℃, add 0.3g tin tetrachloride, add dropwise 4.8g 50% citric acid aqueous solution as catalyst, Add 154g of ceric ammonium nitrate, after the addition is completed, react at a constant temperature for 3-5 hours, and let stand to separate layers;

[0036] (2) The organic phase of the lower layer after the above layering is washed 2-4 times with each 50ml 5% NaOH solution at a constant temperature of 25°C, and the washing time is 0.5-1h to remove impurities, and then 50ml of distilled water is used to wash The organic phase was washed several times with water, and the lower organic phase was dried with anhydrous calcium chloride solid;

[0037] (3) Add 1g Zr(OH) to the above dried organic phase 4 and 0.2g of phosphoric acid, at a temperature of 15°C-25°C, add 80ml of dimethyl sulfoxide solution containing 10g of NBS, heat up to 90-100°C ...

Embodiment 2

[0039] (1) Dissolve 10g of SBS with 70ml of organic solvent chloroform, add 180g of 45% aqueous solution of tetraethylammonium bromide, heat up to 25°C, add 0.3g of tin tetrachloride, add 154g of cerium ammonium nitrate, after the addition is completed, the constant temperature reaction is 3- 5 hours, let stand and stratify;

[0040] (2) The organic phase of the lower layer after the above layering is washed 2-4 times with each 50ml 5% NaOH solution at a constant temperature of 25°C, and the washing time is 0.5-1h to remove impurities, and then 50ml of distilled water is used to wash The organic phase was washed several times with water, and the lower organic phase was dried with anhydrous calcium chloride solid;

[0041] (3) Add 1g Zr(OH) to the above dried organic phase 4 and 0.2g of phosphoric acid, at a temperature of 15°C-25°C, add 80ml of dimethyl sulfoxide solution containing 10g of NBS, heat up to 90-100°C and reflux for 1-2 hours, and neutralize the excess with sodiu...

Embodiment 3

[0043] (1) Dissolve 10g SBS with 70ml organic solvent chloroform, add 180g 45% tetraethylammonium bromide aqueous solution, be warming up to 25 ℃, add 0.3g tin tetrachloride, add dropwise 4.8g 50% sodium carbonate aqueous solution as catalyst, Add 154g of ceric ammonium nitrate, after the addition is completed, react at a constant temperature for 3-5 hours, and let stand to separate layers;

[0044] (2) The organic phase of the lower layer after the above layering is washed 2-4 times with each 50ml 5% NaOH solution at a constant temperature of 25°C, and the washing time is 0.5-1h to remove impurities, and then 50ml of distilled water is used to wash The organic phase was washed several times with water, and the lower organic phase was dried with anhydrous calcium chloride solid;

[0045] (3) Add 1g Zr(OH) to the above dried organic phase 4 and 0.2g of phosphoric acid, at a temperature of 15°C-25°C, add 80ml of carbon tetrachloride solution containing 10g of NBS, heat up to 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com