Preparation method of thermosetting polyimide

A polyimide and thermosetting technology, applied in the field of preparation of thermosetting polyimide, can solve the problems of low mechanical strength, low transition temperature, and the failure of reprocessing and recycling of high-performance polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of thermosetting polyimide, comprises the following steps:

[0026] 1) Diamine, dianhydride and organic solvent are mixed, carry out polycondensation reaction, obtain the polyamic acid solution of diamine termination;

[0027] 2) mixing the diamine-terminated polyamic acid solution with toluene to carry out an imidization reaction to obtain a polyimide oligomer;

[0028] 3) Mixing the polyimide oligomer, trimesaldehyde and an organic solvent for cross-linking and condensation reaction to obtain a thermosetting polyimide.

[0029] The invention mixes diamine, dianhydride and organic solvent to carry out polycondensation reaction to obtain diamine-terminated polyamic acid solution. In the present invention, the diamine is preferably 3,3'-diaminodiphenyl ether, 4,4'-diaminodiphenyl sulfone, 4,4'-diaminodiphenyl ether, 2,2-bis[ One of (4-aminophenoxy)phenyl]propane, 4,4'-diaminodiphenylmethane, 1,4-butanediamine and 1,4-...

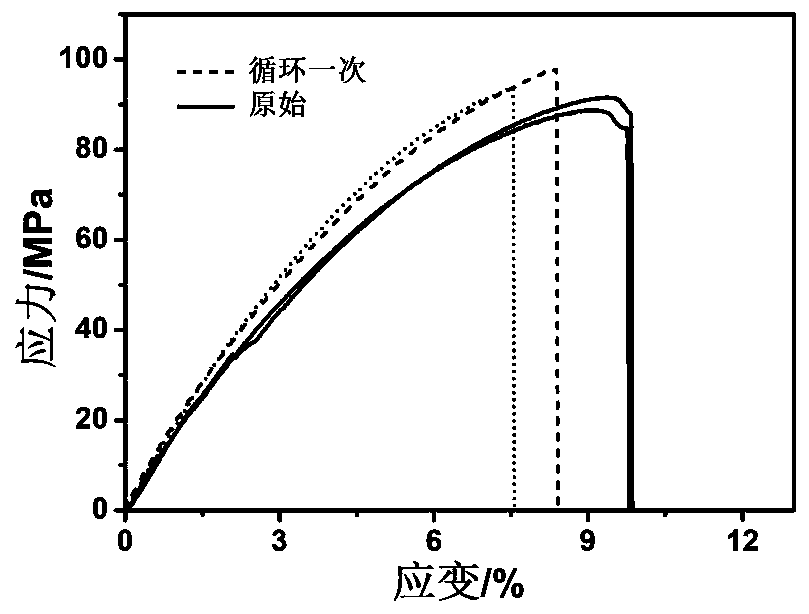

Embodiment 1

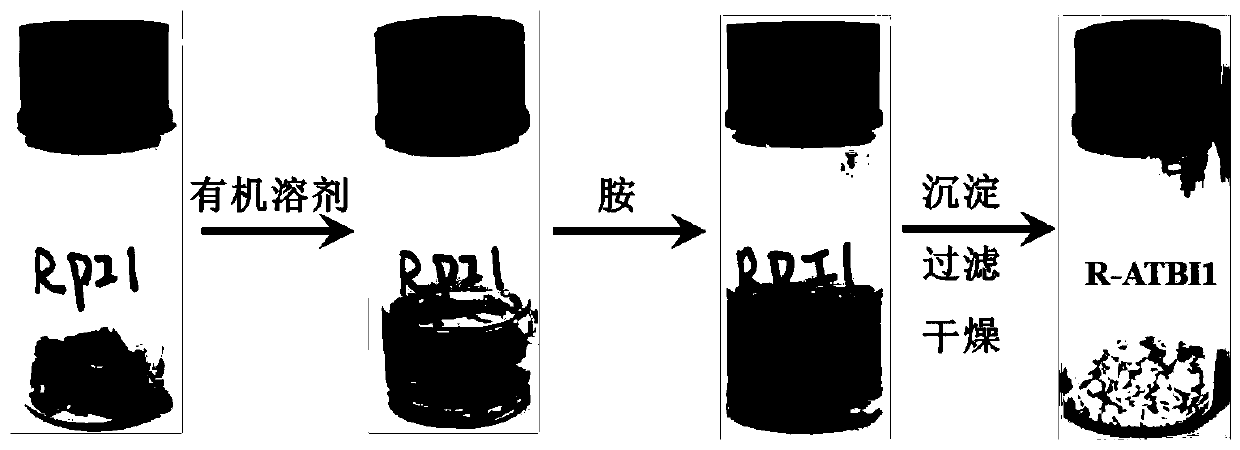

[0042] Dissolve 4,4'-diaminodiphenyl ether (10 mmol) in N-methyl-2-pyrrolidone, stir at room temperature under a dry nitrogen atmosphere until completely dissolved, then add bisphenol A diether dianhydride ( 5mmol), stir 12h under nitrogen atmosphere, ice-water bath condition, carry out polycondensation reaction, obtain the polyamic acid solution of diamine termination; In described polyamic acid solution, add toluene (toluene and N-methyl-2-pyrrolidone Volume ratio 1:10), reflux at 250°C for 5h to carry out imidization reaction; after cooling to room temperature, pour the resulting reaction liquid into methanol to precipitate solids, vacuum filter the resulting system, wash with toluene three times, and Vacuum drying at 80°C to obtain a polyimide oligomer;

[0043] Add N-methyl-2-pyrrolidone (10mL) in the polyimide oligomer (1mmol), stir constantly until completely dissolving to obtain a transparent solution, add trimesaldehyde-containing N to the solution. ,N-Dimethylformam...

Embodiment 2

[0049] Dissolve 4,4'-diaminodiphenyl ether (10 mmol) in N-methyl-2-pyrrolidone, stir at room temperature under a dry nitrogen atmosphere until completely dissolved, then add 4,4'-(hexafluoroiso Propylene) diphthalic anhydride (5mmol), stir 10h under nitrogen atmosphere, ice-water bath condition, carry out polycondensation reaction, obtain the polyamic acid solution of diamine termination; In described polyamic acid solution, add toluene (toluene and N-formaldehyde Base-2-pyrrolidone volume ratio 1:10), reflux at 220°C for 8h to carry out imidization reaction; after cooling to room temperature, pour the reaction liquid into ethanol to precipitate solids, vacuum filter the obtained system, and use Washing with toluene three times and drying in vacuum at 100°C to obtain a polyimide oligomer;

[0050] Add N-methyl-2-pyrrolidone (10mL) in the polyimide oligomer (1mmol), stir constantly until completely dissolving to obtain a transparent solution, add trimesaldehyde-containing N to ...

PUM

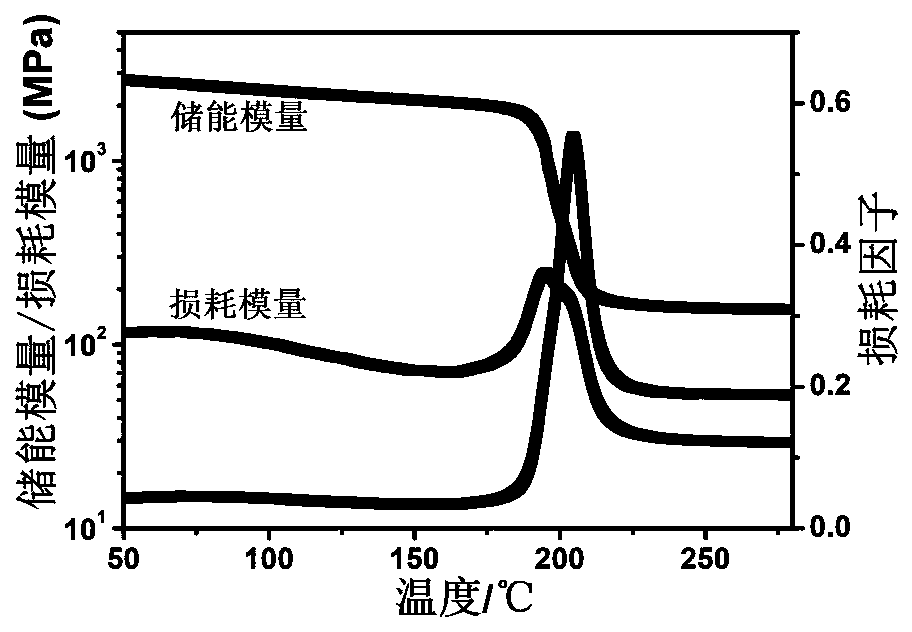

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com