Extraction and separation method of nicotiflorin in rose flower

A separation method, rose flower technology, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problem of extraction and separation of pyroside from rose flower, and achieve easy elution and regeneration, wide biological activity , good selectivity of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

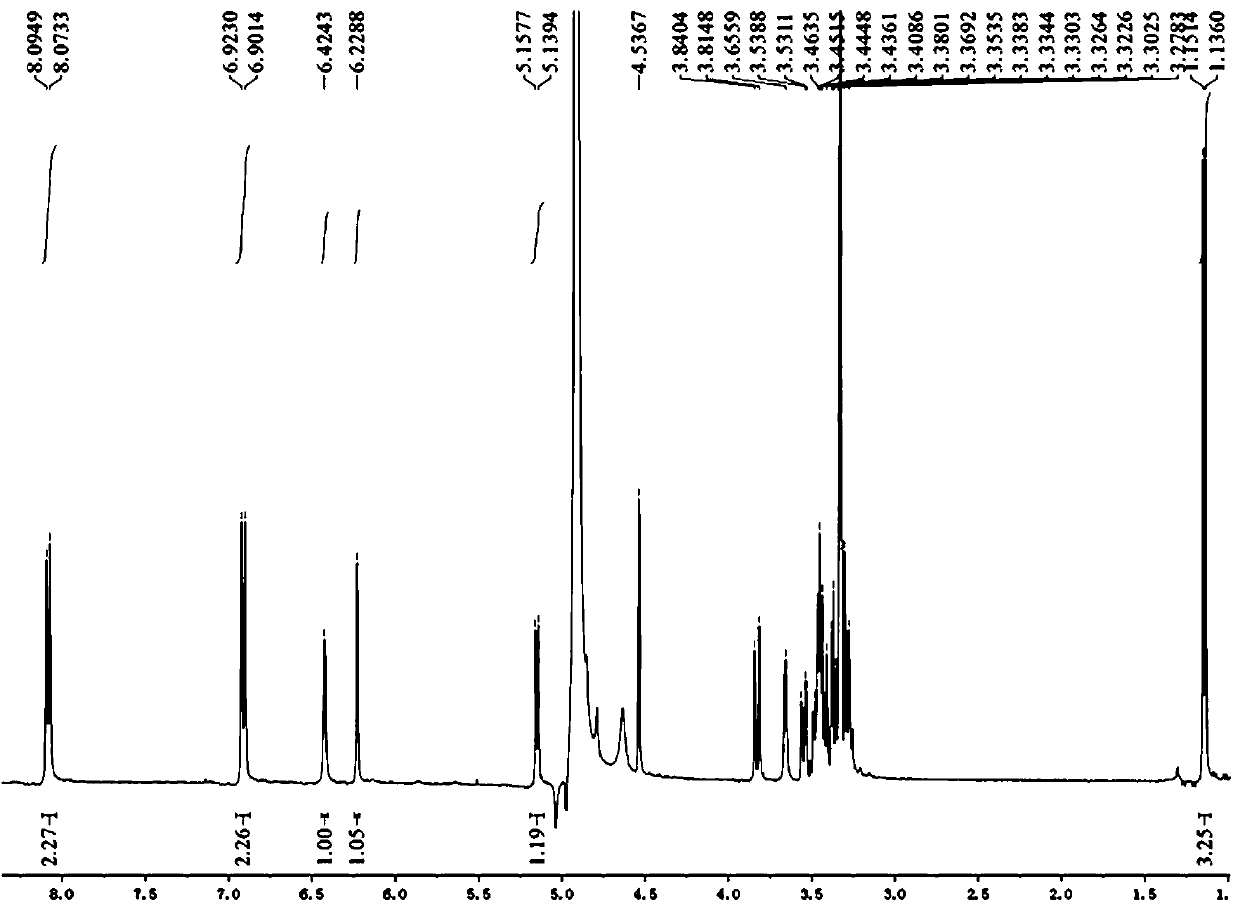

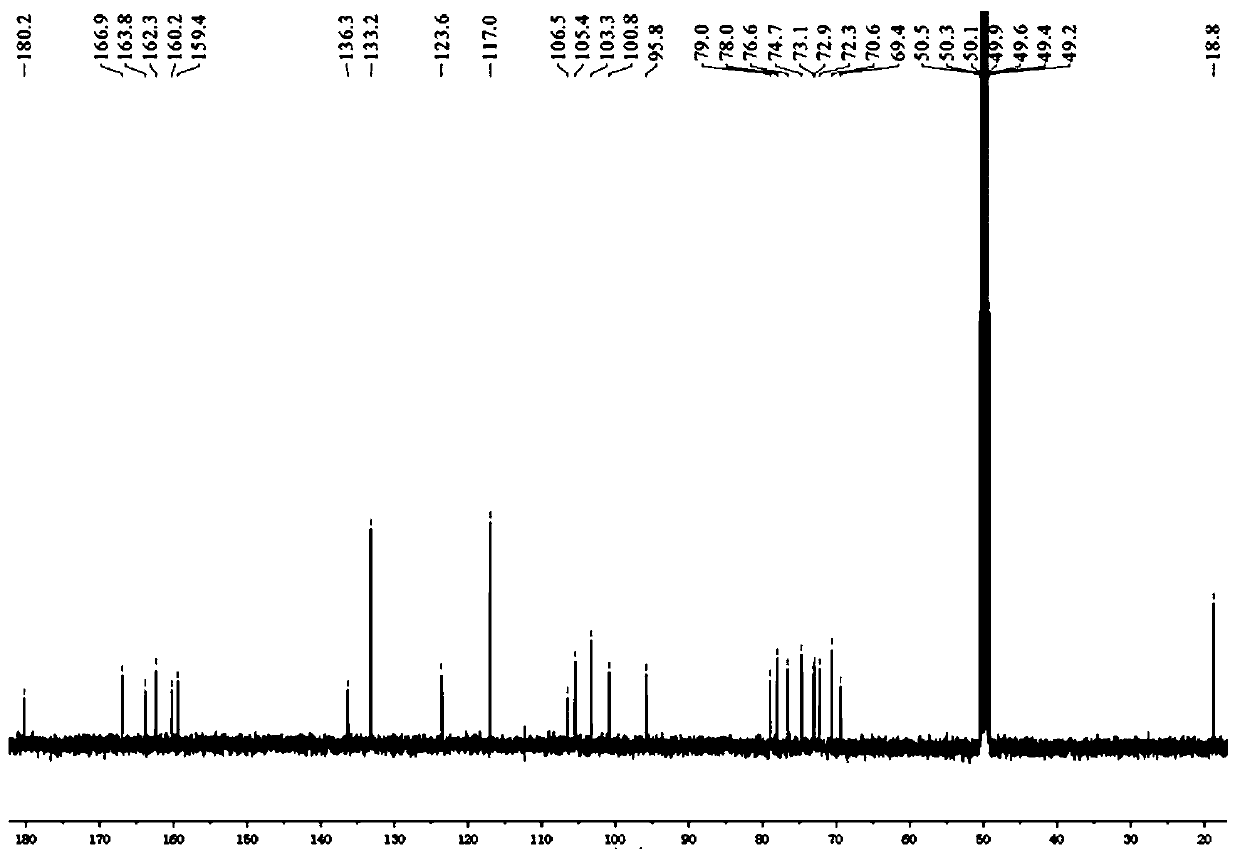

Image

Examples

Embodiment 1

[0025] A method for extracting and separating nicotinic glycosides from rose flowers, comprising the steps of:

[0026] 1) Take 2kg of dried rose flowers, crush them, and degrease them with petroleum ether for 3 times at room temperature. Extraction 3 times, each cold soaking extraction time is 7 days, 3 days, 3 days respectively, the extracts are combined and concentrated to obtain 600 g of total ethanol extract; among them, the addition ratio of dried rose flower and petroleum ether is 1kg: 5L , the addition ratio of residue and ethanol is 1kg:5L;

[0027] 2) Dissolve the total ethanol extract (600 g) with an appropriate amount of methanol and mix the sample with a D101 macroporous resin column (600 g). After chromatography on a D101 macroporous resin column, wash with water, 20% ethanol, and 40% ethanol in sequence. Remove and evaporate the solvent to obtain 40% ethanol elution fraction;

[0028] 3) The fraction eluted with 40% ethanol was eluted by atmospheric silica gel...

Embodiment 2

[0034] A method for extracting and separating nicotinic glycosides from rose flowers, comprising the steps of:

[0035] 1) Take 2kg of dried rose flowers, crush them, and degrease them twice with petroleum ether at room temperature. Extracted 2 times, each cold soaking extraction time was 7 days and 3 days respectively, the extracts were combined and concentrated to obtain 490 g of total ethanol extract; among them, the addition ratio of dried rose flower and petroleum ether was 1 kg: 6 L, and the residue The addition ratio with ethanol is 1 kg: 6 L;

[0036]2) Dissolve the total ethanol extract (490 g) with an appropriate amount of methanol and mix the sample with a D101 macroporous resin column (490 g). After chromatography on a D101 macroporous resin column, elute with water, 20% ethanol, and 40% ethanol in sequence , evaporate the solvent to obtain 40% ethanol elution fraction;

[0037] 3) The fraction eluted with 40% ethanol was eluted by atmospheric silica gel column c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com