Bone repair material and preparation method thereof

A technology for bone repair and mixture, applied in the field of materials, can solve the problems of space improvement and limited application of mechanical properties and biological properties, and achieve the effects of excellent mechanical properties and biological properties, promotion of bone healing, and better biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) The selected nano-hydroxyapatite (nano-hydroxyapatite, nHA) and zirconia (yttria-stabilized tetragonal zirconia, YTZ) are both nano-scale, the particle size of nHA is 80-100nm, and the particle size of YTZ is 70-100nm; Polyamide 66 (polyamide 66, PA66), the molecular weight of PA66 is 30000, and the relative viscosity is 3.2.

[0032] (2) First, the nHA and YTZ powders were placed in a planetary ball mill at a mass ratio of 3:2 for grinding and mixing for 8 hours. Put the mixture into an alumina crucible, compact it, and place it in a numerically controlled electric furnace for high-temperature sintering. The heating steps and time parameters are: room temperature-600°C, 300 minutes; 600°C-850°C, 100 minutes; 850°C-1500°C; The temperature was maintained at 1500°C for 4 hours. After the sintering procedure was completed, the temperature was naturally lowered to 100°C before the furnace was turned on.

[0033] (3) The sintered mixture was pulverized, and the nHA / YTZ ...

experiment example 1

[0036] Mechanical property test:

[0037] Mechanical properties test According to the ISO527-2-2012 standard, the mechanical properties of bone repair materials were tested. The steps are as follows: compressive strength test, sample size: 10×10×4mm, pressurization speed: 5mm / min, compression height ratio: 50%; flexural strength test, sample size: 10×4×80mm, bending span: 60mm , Compression speed: 5mm / min, bending degree: 15mm; tensile strength, elongation at break and elastic modulus test, sample size: 10×4×100mm, gauge length: 60mm, tensile speed: 5mm / min , see Table 1 for details.

[0038] Table 1. Mechanical strength test

[0039]

[0040] It can be seen from Table 1 that compared with the existing nHA / PA66, the bone repair material prepared in Example 1 of the present invention can meet the requirements in terms of compressive strength, tensile strength, flexural strength, and elongation at break. .

experiment example 2

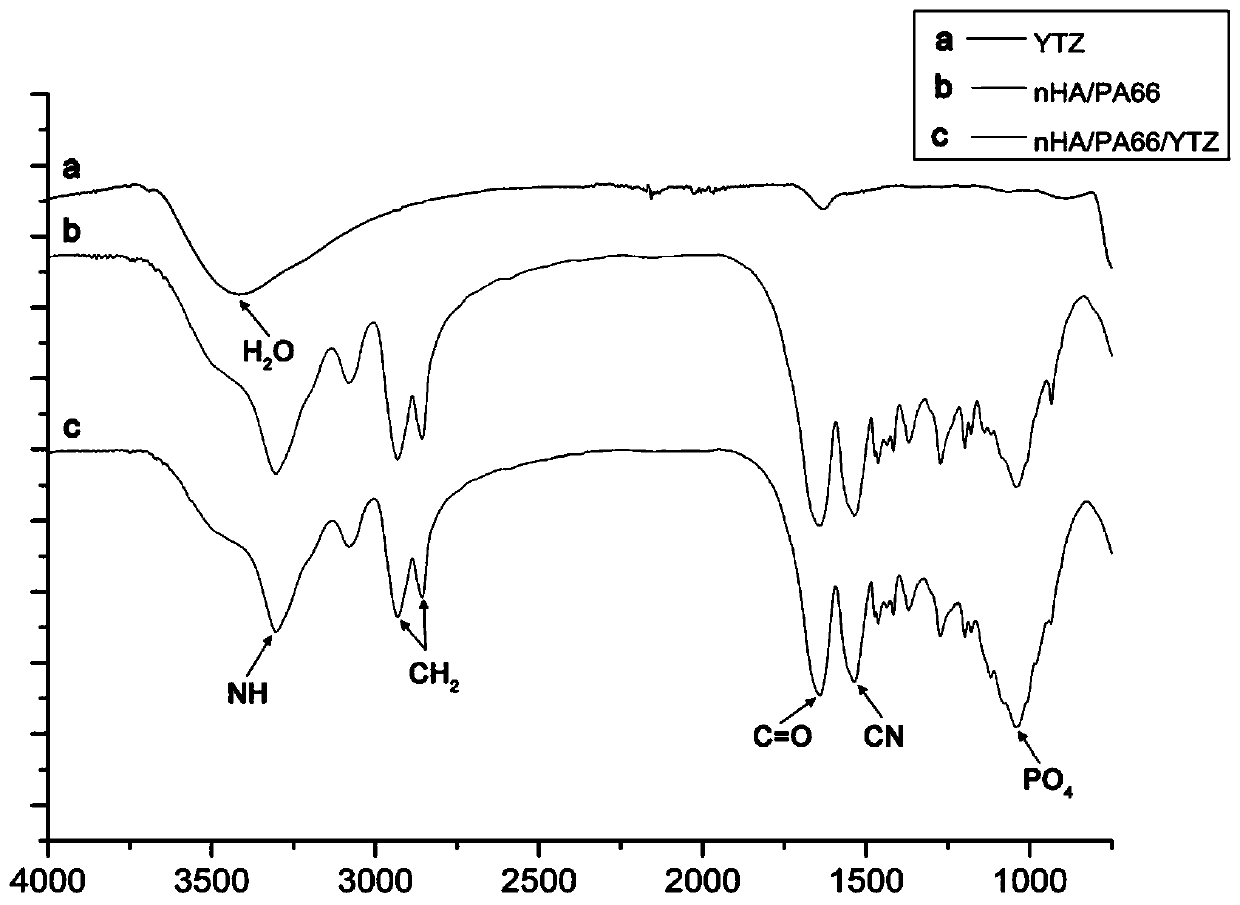

[0042] Fourier transform infrared spectroscopy analysis of bone repair materials, figure 1 The bone repair material infrared spectrogram that is prepared for embodiment 1; figure 1 It can be seen that the test is a test of the functional group composition of the material, indicating that the bone repair material nHA / PA66 / YTZ prepared by the method of the present invention has a stable chemical structure and no change in functional groups.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com