Modified starch coated inhibiting and anti-collapse agent for drilling fluid and preparation method thereof

A technology of drilling fluid and anti-slump agent, which is applied to chemical instruments and methods, drilling compositions, etc., can solve the problem of increasing the thickness of the hydration film on the surface of clay particles, not hindering the hydration dispersion, and reducing the filtration loss of drilling fluid. and other problems, to achieve the effect of enhancing the coating effect, maintaining the stability of the well wall, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

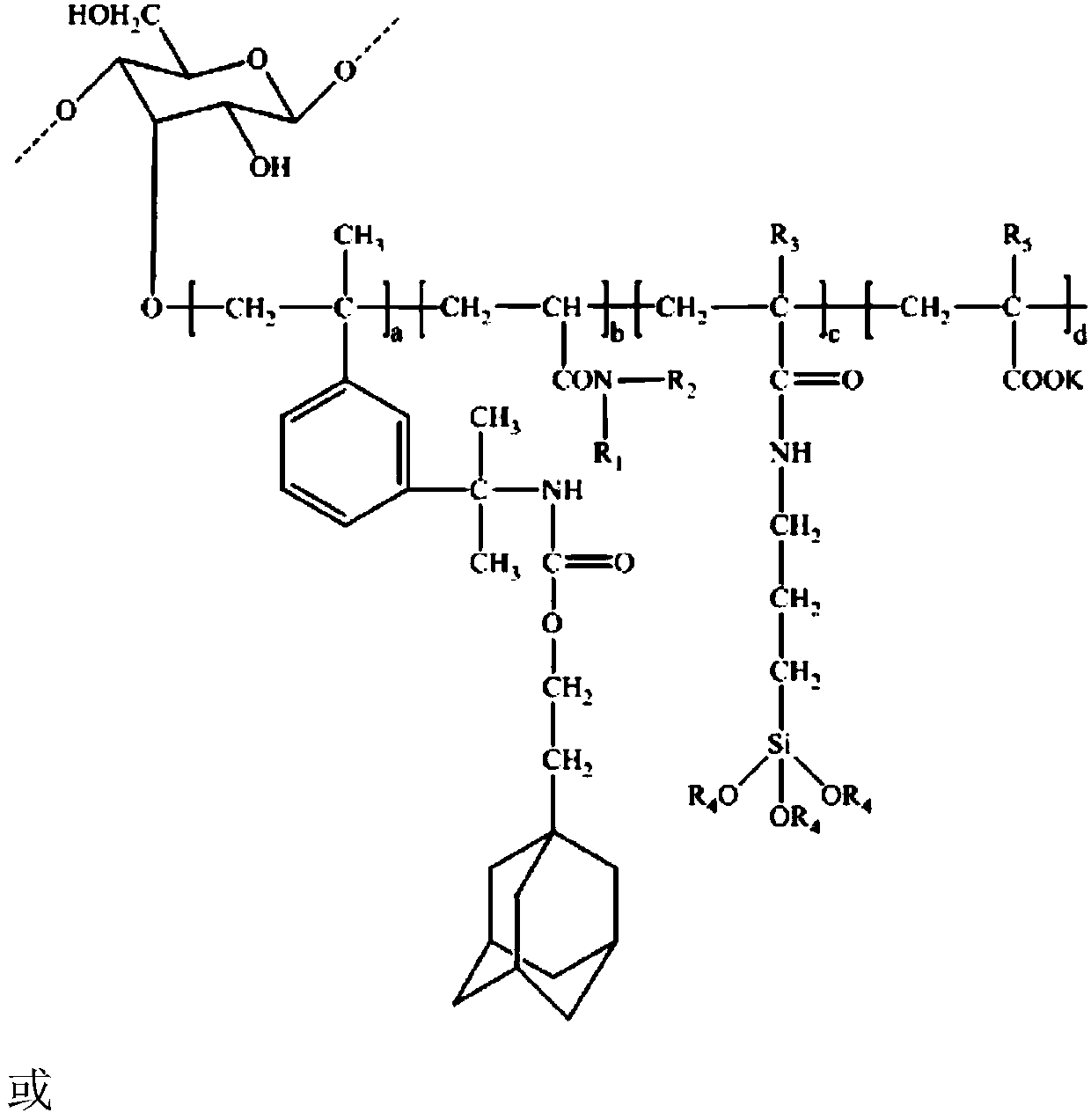

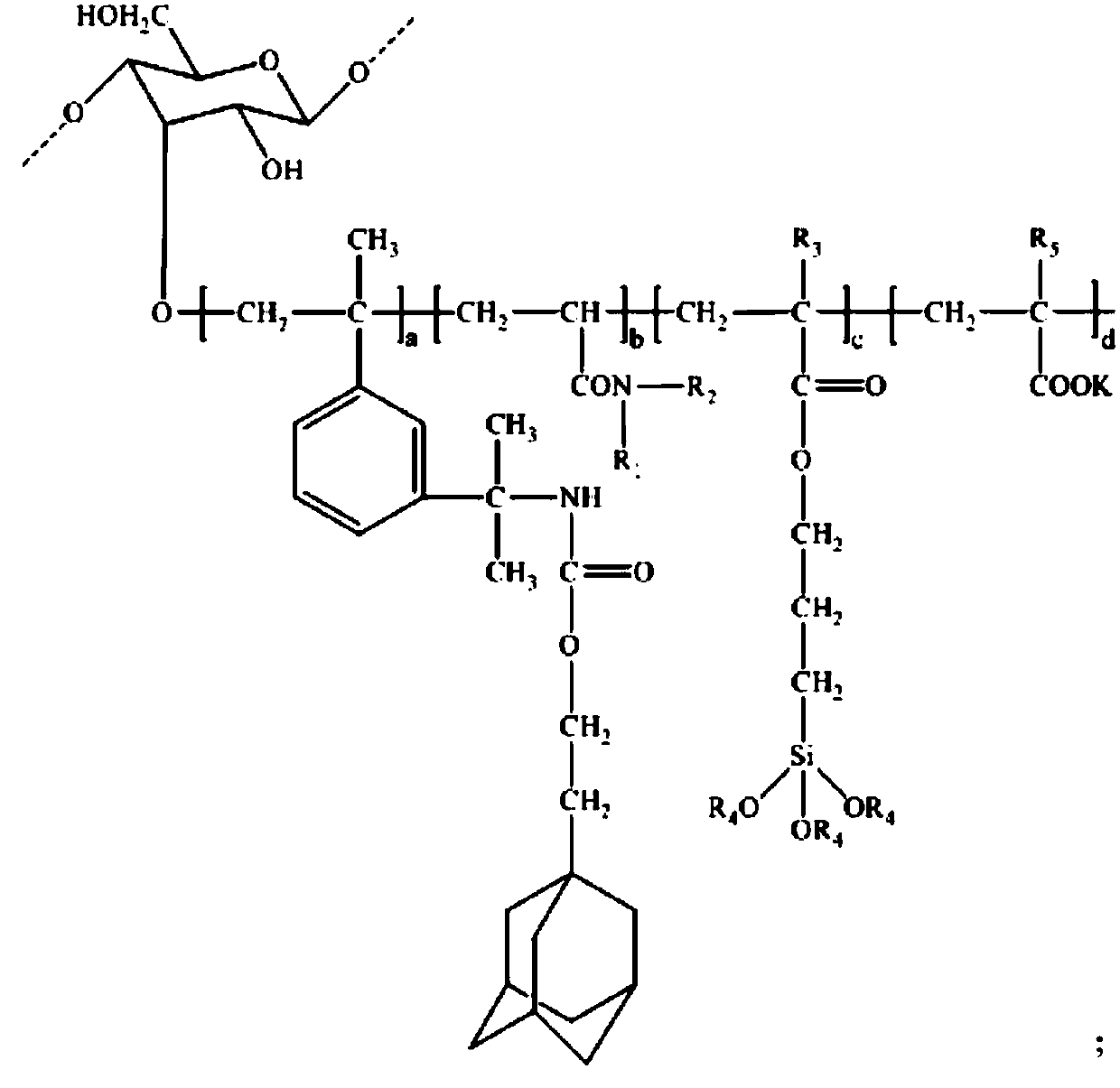

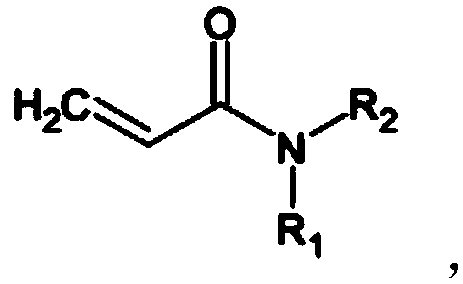

Method used

Image

Examples

Embodiment 1

[0050] Synthesis of Hydrophobic Monomers Containing Phenyl and Adamantyl:

[0051] Add 400mL of acetone and 90.14g of 1-hydroxyethyladamantane into a dry three-neck flask equipped with a stirrer, condenser and dropping funnel, heat in a water bath to 50°C, and vacuum for 2 hours to remove moisture. Under nitrogen protection, 0.03 g of dibutyltin dilaurate was added. 102.64 g of 3-isopropyl-dimethylbenzyl isocyanate in the dropping funnel was dropped into the three-necked flask, and reacted for 6.5 hours to obtain a light yellow oily liquid. The light yellow oily liquid was placed in water, filtered, allowed to stand to separate layers, and the oily liquid in the lower layer was taken out, and placed in an oven at 60°C until constant weight to obtain the target hydrophobic monomer.

Embodiment 2

[0053] Mix 200g of starch with 1800mL of water to obtain starch milk with a concentration of 10.0%, heat the starch milk in a water bath at 60°C; add 0.02g of α-amylase to the above-mentioned hot starch milk, continue the reaction for 6.0h and then raise the temperature to 110°C Inactivate for 1.0 h to obtain enzyme-degraded starch emulsion, dry to constant weight to obtain partially degraded starch, and set aside.

[0054] Dissolve 200g of acrylic acid in 800mL of water, add KOH solution with a concentration of 50% by mass, adjust the pH to 8.5, place it in a vacuum drying oven, and dry it to constant weight at 25°C to obtain potassium acrylate, which is ready for use.

[0055] Add 280g partially degraded starch, 56.86g acrylamide, 22.03g potassium acrylate, 1.38g gamma-(acrylamido) propyltriethoxysilane and 3300g 1,4-dioxane successively in the reactor, stir until the monomer is completely dissolved. 0.77 g of the hydrophobic monomer prepared in Example 1 was added, and nit...

Embodiment 3

[0058] Mix 150g of starch with 850mL of water to obtain starch milk with a concentration of 15.0%, heat the starch milk in a water bath at 60°C; add 0.02g of α-amylase to the above-mentioned hot starch milk, continue the reaction for 6.0h and then raise the temperature to 110°C Inactivate for 2.0 hours to obtain enzyme-degraded starch emulsion, dry to constant weight to obtain partially degraded starch, and set aside.

[0059] Dissolve 100g of methacrylic acid in 900mL of water, add KOH solution with a mass percent concentration of 50%, adjust the pH to 8.5, place it in a vacuum drying oven, and dry it to constant weight at 25°C to obtain potassium methacrylate. spare.

[0060] Add 215g partially degraded starch, 79.30g N, N-dimethylacrylamide, 24.83g potassium methacrylate, 1.98g gamma-(methacryloxy) propyltrimethoxysilane and 2893g tetrahydrofuran successively in the reactor, stir until the monomer is completely dissolved. Add 0.76 g of hydrophobic monomers, blow nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com