Light power communication fireproof cable and preparation method thereof

A technology for power communication and fireproof cables, which is applied to power cables, communication cables, and power cables including electronic control, etc., can solve the problems of incombustibility of cables, inflammability of cables, and heavy cable quality, and achieves reasonable process design, resistance to resistance, etc. The effect of improving the mechanical properties and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

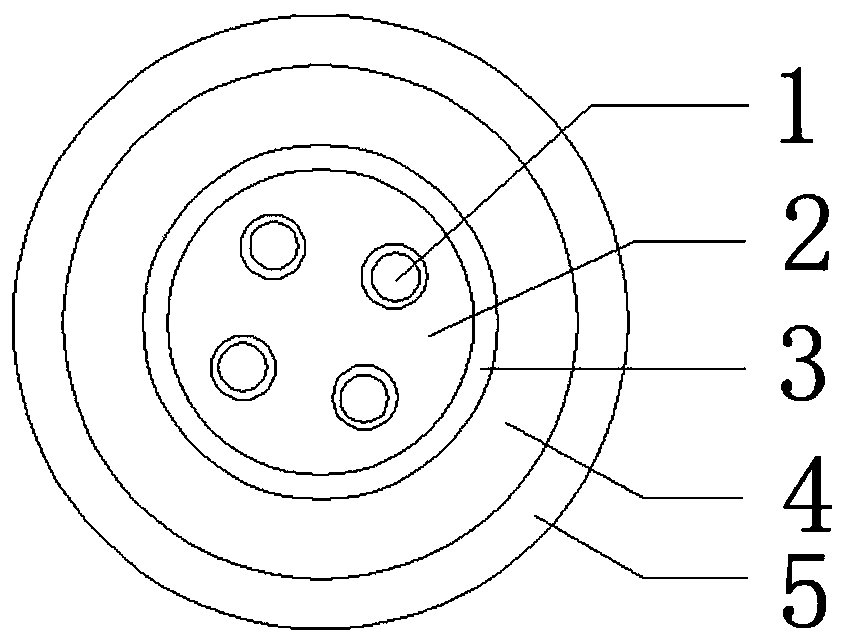

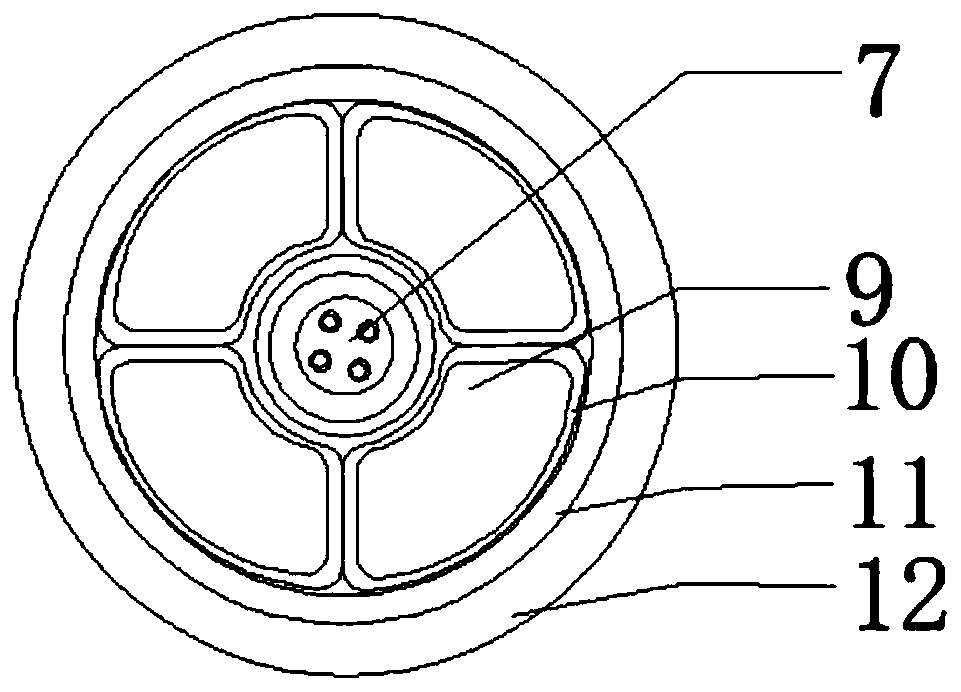

[0043] like figure 1 and image 3 As shown, a light-duty power communication fireproof cable, which includes a carbon fiber / glass fiber optical fiber composite mandrel 7, a special-shaped conductor 9 wrapped around the outer periphery of the carbon fiber / glass fiber optical fiber composite mandrel 7, wrapped around the outer layer of the special-shaped conductor 9 The insulating tape 10, the wrapping tape 11 wrapped around the outer layer of the insulating tape 10, the seamless embossed tube 12 wrapped around the outer layer of the wrapping tape 11;

[0044] The carbon fiber / glass fiber composite mandrel 7 is a single mandrel structure;

[0045] The single-core rod structure includes 4 colored single-mode or multi-mode optical fibers 1 of the optical signal transmission medium, a protective tube 3 wrapped around the outer periphery of the colored single-mode or multi-mode optical fiber 1, and a filling ointment filled in the protective tube 3 2. The carbon fiber reinforced l...

Embodiment 2

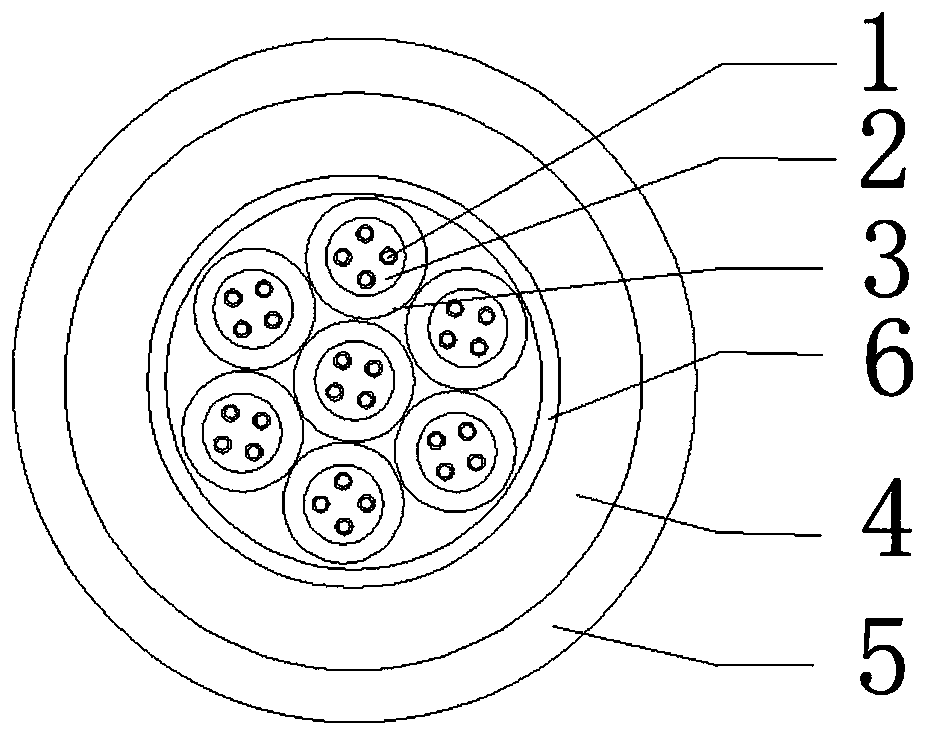

[0050] like figure 2 and image 3 As shown, a light-duty power communication fireproof cable, which includes a carbon fiber / glass fiber optical fiber composite mandrel 7, a special-shaped conductor 9 wrapped around the outer periphery of the carbon fiber / glass fiber optical fiber composite mandrel 7, wrapped around the outer layer of the special-shaped conductor 9 The insulating tape 10, the wrapping tape 11 wrapped around the outer layer of the insulating tape 10, the seamless embossed tube 12 wrapped around the outer layer of the wrapping tape 11;

[0051] The carbon fiber / glass fiber composite mandrel 7 is a multi-mandrel structure;

[0052] The multi-core rod structure includes a 7-core optical unit, and the optical unit includes 4 colored single-mode or multi-mode optical fibers 1 as optical signal transmission media, a protective tube 3 wrapped around the outer periphery of the colored single-mode or multi-mode optical fiber 1, and filled in the protective tube Fillin...

Embodiment 3

[0057] like figure 1 and Figure 4 As shown, a light-duty power communication fireproof cable, which includes a carbon fiber / glass fiber composite core rod 7, a plurality of circular conductors 9 wrapped around the outer periphery of the carbon fiber / glass fiber composite core rod 7, a single circular conductor 9 The outer layer is wrapped with silicone rubber insulating material 13, and the glass fiber filling rope 14 is filled between the multiple circular conductors 9, and the outer layer of the glass fiber filling rope 14 is wrapped with a wrapping tape 11, and the outer layer of the wrapping tape 11 is armored There is a galvanized steel strip 15, and the outer layer of the galvanized steel strip 15 is wrapped with a halogen-free flame-retardant polyolefin outer sheath 16.

[0058] In the above-mentioned light-duty power communication fireproof cable, the wrapping tape 11 is a glass cloth tape or a polypropylene wrapping tape.

[0059] In the light-duty power communicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com