Polyaspartic acid enzyme carbon-based bacterium bio-organic fertilizer and production method thereof

A technique for the biological and production methods of polytetrazyme carbon-based bacteria, which is applied in the direction of organic fertilizers, nitrogen fertilizers, fertilization devices, etc., can solve the problems of polluting the atmosphere and groundwater, occupying land, and polluting eutrophication of water bodies, so as to prolong the survival rate and Improvement of shelf life, degree of soil compaction, and improvement of fertilizer utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A bio-organic fertilizer for polytetracycline carbon-based bacteria, comprising the following raw materials in parts by weight: 300 parts of fermented livestock and poultry manure, 300 parts of humic acid, parts of zinc sulfate, parts of boric acid, 5 parts of tetrasodium iminodisuccinate, and composite microorganisms 6 parts of bacterial strains, 3 parts of nano-activated carbon, 3 parts of polyaspartic acid, and 3 parts of polyglutamic acid; .

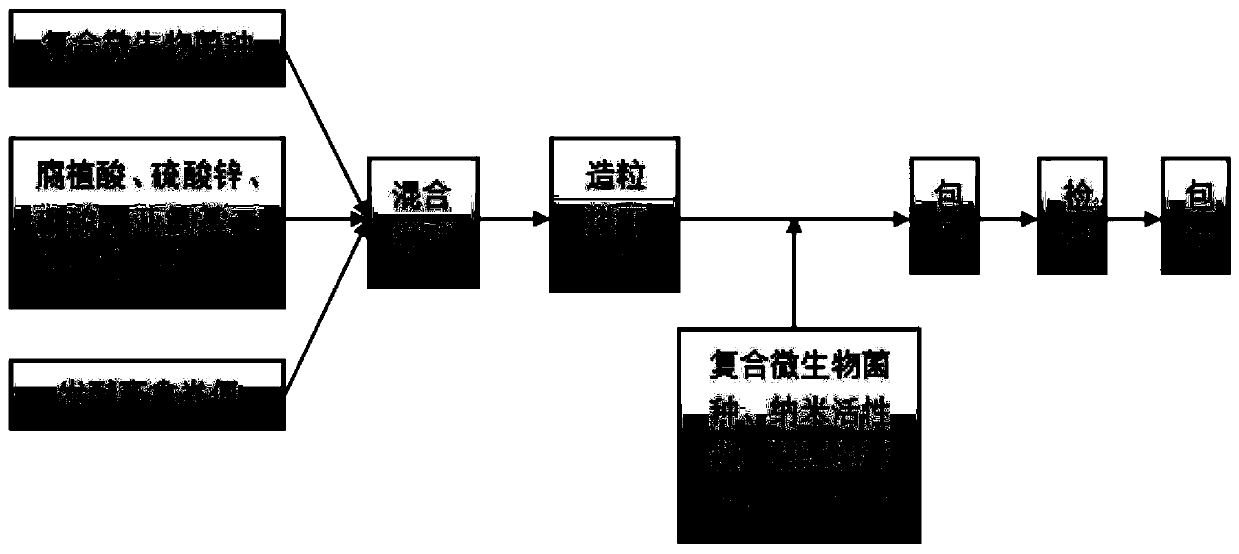

[0020] A method for producing bio-organic fertilizer of polyastrin carbon-based bacteria, comprising the following steps:

[0021] (1) Divide the composite microbial strain into two equal parts, first add a part of it and the fermented livestock and poultry manure, humic acid, zinc sulfate, boric acid, tetrasodium iminodisuccinate mixed fermentation;

[0022] (2) After crushing, granulating, drying and sieving, activated humic acid particles are obtained;

[0023] (3) The activated humic acid particles are passed through the...

Embodiment 2

[0027] A bio-organic fertilizer for polytetracycline carbon-based bacteria, comprising the following raw materials in parts by weight: 350 parts of fermented livestock and poultry manure, 350 parts of humic acid, 75 parts of zinc sulfate, 75 parts of boric acid, 7.5 parts of tetrasodium iminodisuccinate, 8 parts of composite microbial strains, 4 parts of nano activated carbon, 4 parts of polyaspartic acid, and 4 parts of polyglutamic acid; the composite microbial strains include Bacillus subtilis, Bacillus licheniformis, jelly-like Bacillus, giant bacillus.

[0028] A method for producing bio-organic fertilizer of polyastrin carbon-based bacteria, comprising the following steps:

[0029] (1) Divide the composite microbial strain into two equal parts, first add a part of it and the fermented livestock and poultry manure, humic acid, zinc sulfate, boric acid, tetrasodium iminodisuccinate mixed fermentation;

[0030] (2) After crushing, granulating, drying and sieving, activated...

Embodiment 3

[0035] A bio-organic fertilizer for polytetracycline carbon-based bacteria, comprising the following raw materials in parts by weight: 400 parts of fermented livestock and poultry manure, 400 parts of humic acid, 100 parts of zinc sulfate, 100 parts of boric acid, 10 parts of tetrasodium iminodisuccinate, 10 parts of composite microbial strains, 5 parts of nano activated carbon, 5 parts of polyaspartic acid, and 5 parts of polyglutamic acid; the composite microbial strains include Bacillus subtilis, Bacillus licheniformis, Bacillus jelly-like, giant bacillus.

[0036] A method for producing bio-organic fertilizer of polyastrin carbon-based bacteria, comprising the following steps:

[0037] (1) Divide the composite microbial strain into two equal parts, first add a part of it and the fermented livestock and poultry manure, humic acid, zinc sulfate, boric acid, tetrasodium iminodisuccinate mixed fermentation;

[0038] (2) After crushing, granulating, drying and sieving, activat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap