Preparation method and application of silk fibroin and chitin blended nanofiber embedded hydrogel cartilage biomimetic scaffold

A silk fibroin and nanofiber technology, applied in fiber treatment, tissue regeneration, electrospinning, etc., to achieve high water content, promote tissue regeneration, and facilitate adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Obtain regenerated silk fibroin from silkworm cocoons, purify industrial grade chitin (Aladdin), weigh regenerated silk fibroin and purified chitin according to the ratio of silk fibroin: purified chitin = 6:1 , respectively dissolve the two in the organic solvent HFIP, stir until clear and transparent, mix the two solutions, and keep the final concentration of silk fibroin at 6% (w / w).

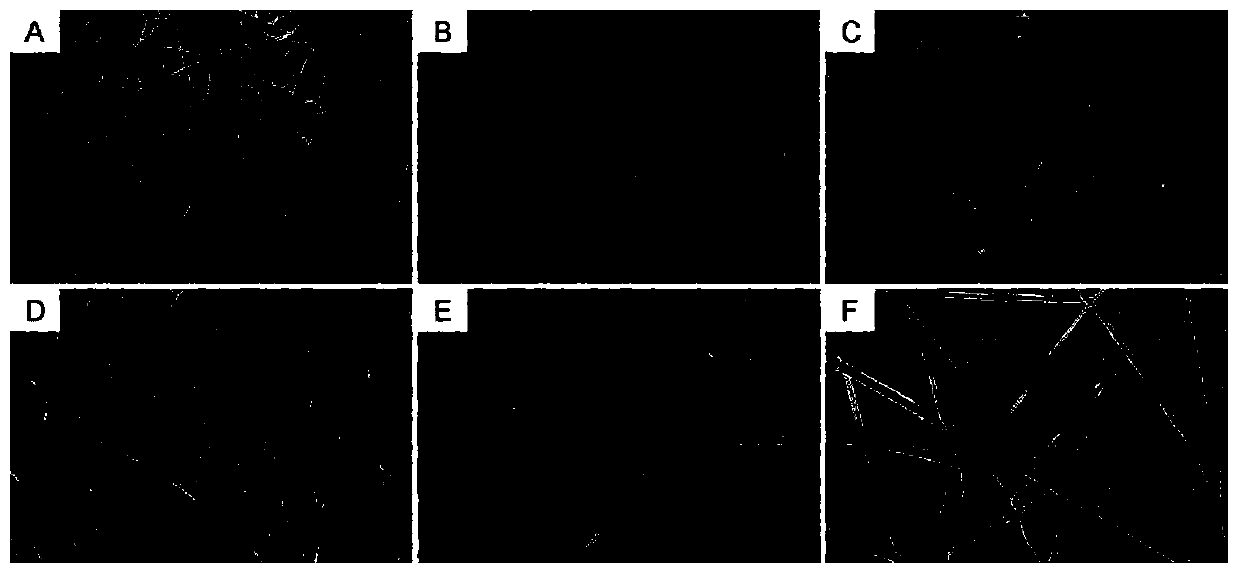

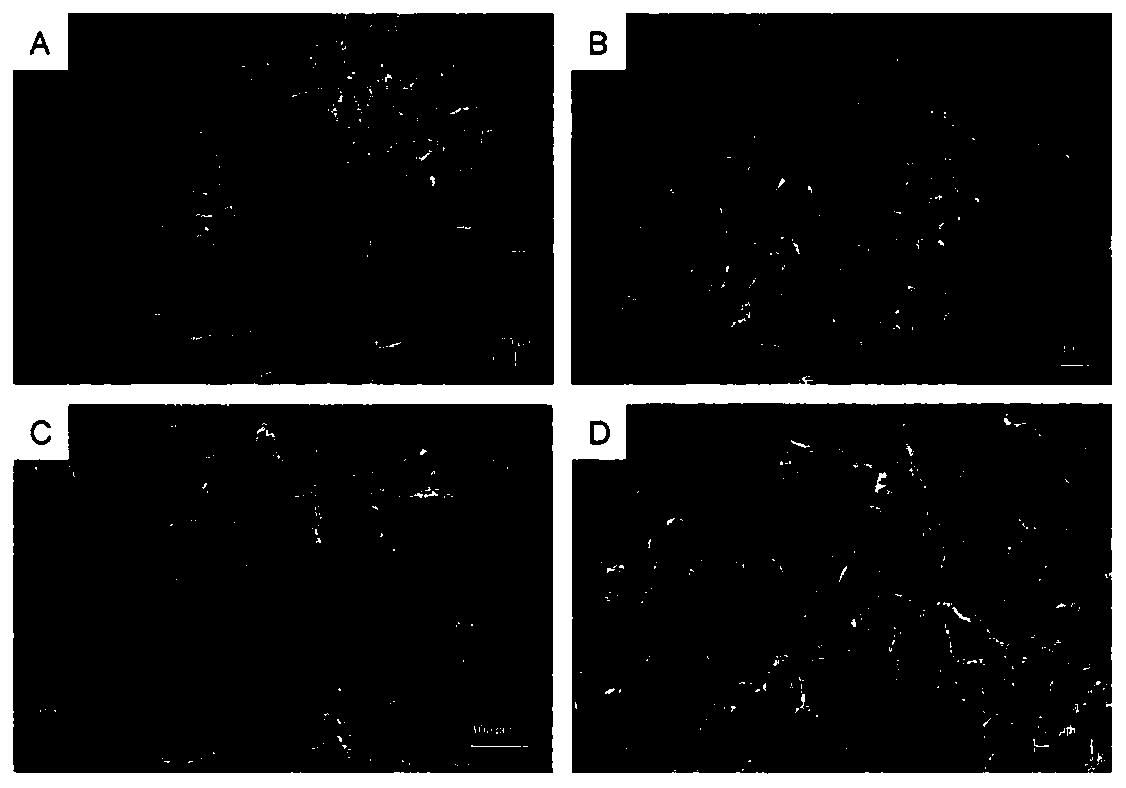

[0039] (2) The mixed solution is electrospun to obtain blended nanofibers. The electrospinning conditions are voltage 16kV, flow rate 0.8mL / h, distance between the aluminum foil plate receiver and the needle head 15cm, relative temperature and relative humidity are 25°C and 50% respectively , the resulting blended nanofiber membrane was dried in a vacuum oven for 3 days to remove residual HFIP, and the field emission scanning electron microscope image of the nanofiber membrane was as follows figure 2 A&D shown. The water insolubility is increased after ethanol gradient cross-link...

Embodiment 2

[0045] (1). Regenerated silk fibroin is obtained from silkworm cocoons, and industrial-grade chitin (Aladdin) is purified, and silk fibroin and purified chitin are weighed according to the ratio of silk fibroin:purified chitin=7:1 , respectively dissolve the two solutions in the organic solvent HFIP, stir until clear and transparent, mix the two solutions, and keep the final concentration of silk fibroin at 7% (w / w).

[0046] (2). The mixed solution is electrospun to obtain blended nanofibers. The electrospinning conditions are voltage 16kV, flow rate 0.8mL / h, distance between the aluminum foil plate receiver and the needle head 15cm, relative temperature and relative humidity respectively 25 ℃ and 50 %, the resulting blended nanofiber membrane was dried in a vacuum oven for 3 days to remove residual HFIP, and the field emission scanning electron microscope image of the nanofiber membrane is shown in figure 2 Shown by B&E. The water insolubility is increased after ethanol gr...

Embodiment 3

[0050] (1). Obtain regenerated silk fibroin from silkworm cocoons, purify industrial grade chitin (Aladdin), weigh silk fibroin and purified chitin according to the ratio of silk fibroin:purified chitin=8:1 , respectively dissolve the two solutions in the organic solvent HFIP, stir until clear and transparent, mix the two solutions, and keep the final concentration of silk fibroin at 8% (w / w).

[0051] (2). The mixed solution is electrospun to obtain blended nanofibers. The electrospinning conditions are voltage 16kV, flow rate 0.8mL / h, distance between the aluminum foil plate receiver and the needle head 15cm, relative temperature and relative humidity respectively 25 ℃ and 50 %, the resulting blended nanofiber membrane was dried in a vacuum oven for 3 days to remove residual HFIP, and the field emission scanning electron microscope image of the nanofiber membrane is shown in figure 2 C&F shown. The water insolubility is increased after ethanol gradient cross-linking, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com