Intelligent electromagnetic heating type steam generator

A technology of steam generator and heat generator, which is applied in the direction of steam generation, steam generation method, evaporator accessories, etc., can solve the problems of long-distance transmission pipelines with large transmission losses, long transmission pipelines, and large floor space, etc., and achieve good Self-extinguishing, avoiding tube explosion, and enhancing the effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

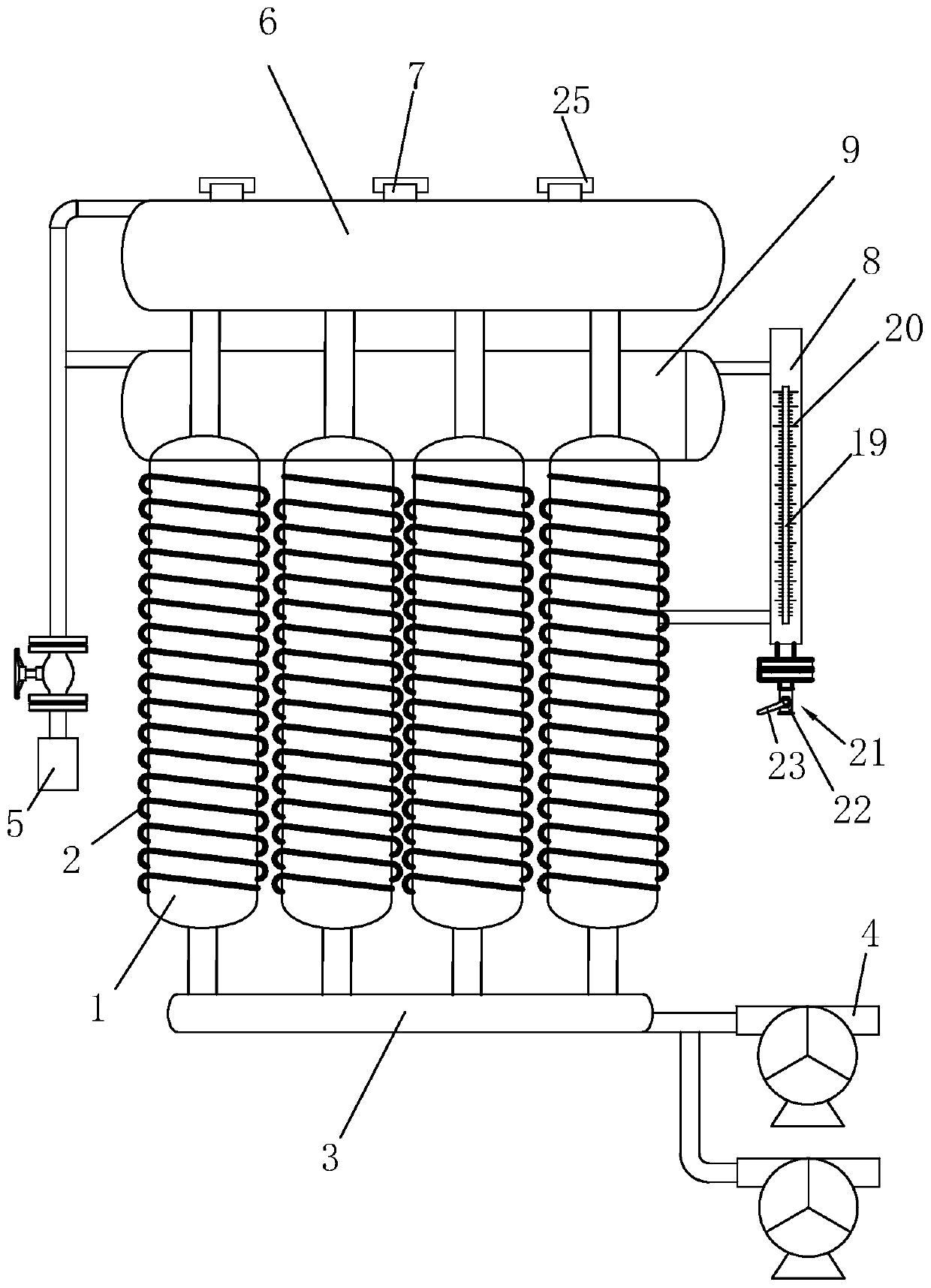

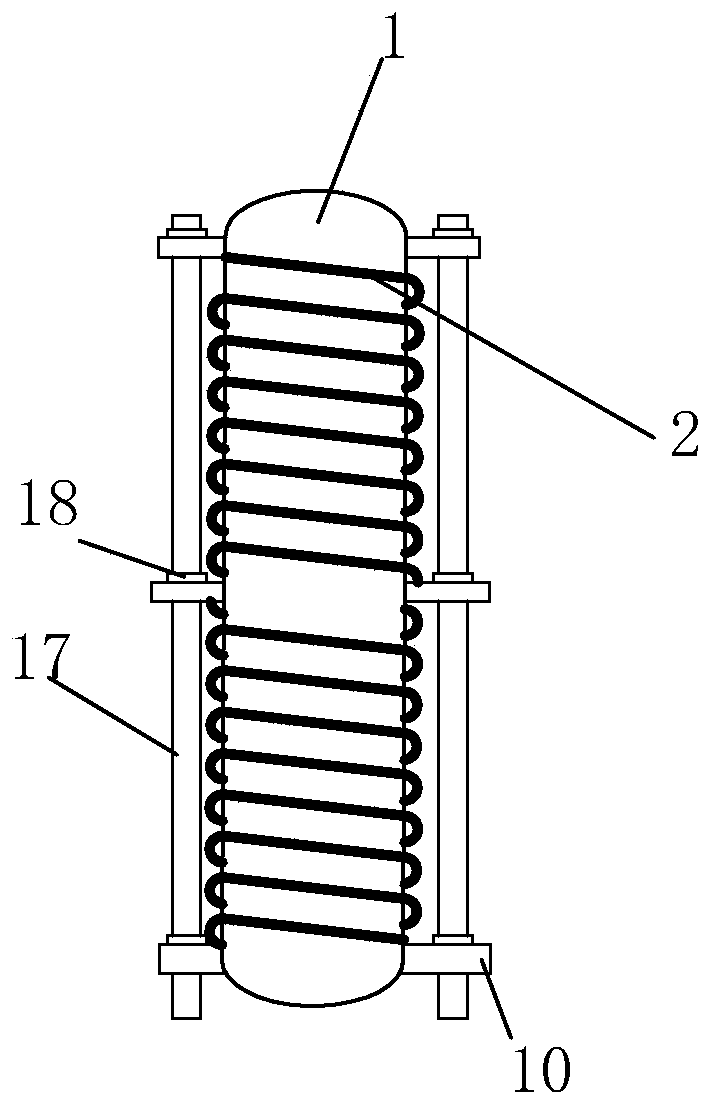

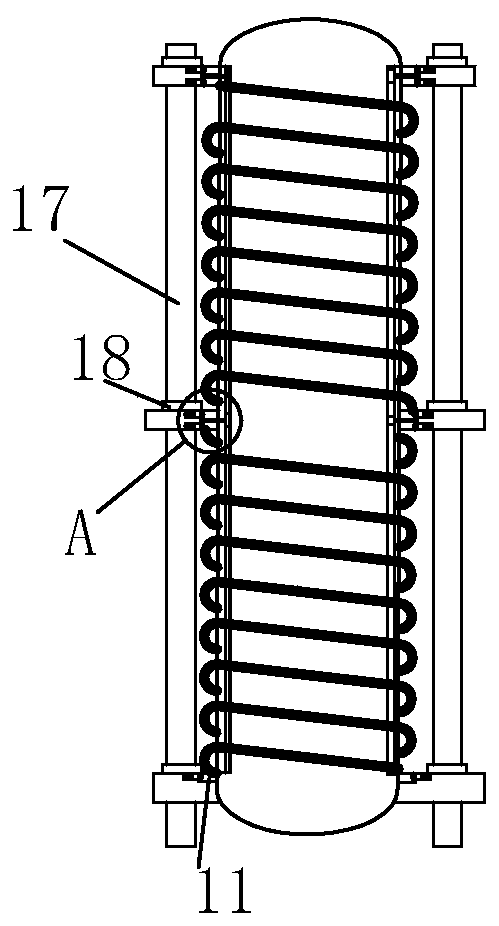

[0043] An electromagnetic heating device such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Figure 8 As shown, it includes a plurality of tube bodies 1, and the tube bodies 1 are arranged in a cylindrical shape, and an electromagnetic heat generator is sheathed on the outside of each of the tube bodies 1, and the electromagnetic generator is used to heat the liquid in the tube body 1. The electromagnetic heat generator includes an electromagnetic induction coil tube 2 sleeved outside the tube body 1. When the electromagnetic induction coil tube 2 is energized, the tube body 1 will be heated to heat the liquid in the tube body 1. The bottoms of the multiple pipe bodies 1 are connected to the same first water inlet pipe 3, one end of the first water inlet pipe 3 is connected to two first water pumps 4, and the top of the first water inlet pipe 3 is connected to a water outlet pipe 6. The side of the water outlet pipe 6 away from the first water inlet pipe...

Embodiment 2

[0064] Embodiment 2: The difference from Embodiment 1 is that the inner side of the pipe body is provided with a thermal insulation material. According to parts by weight, the thermal insulation material includes the following components: 110 parts of urea, 17 parts of urea-formaldehyde resin adhesive, hair 3 parts of foaming agent, 4 parts of surfactant, 60 parts of fly ash, 30 parts of coal gangue fiber, SiO 2 35 parts, phosphorus oxychloride 15 parts, polyether polyol 15 parts, melamine 3 parts,

[0065] The preparation method of the thermal insulation material comprises the following steps,

[0066] S1: Weigh the corresponding components according to the parts by weight, put the urea-formaldehyde resin adhesive, foaming agent urea and surfactant into a glass beaker, and stir evenly with a high-speed stirrer to prepare a foam emulsion;

[0067] S2: Add phosphorus oxychloride to the foam emulsion and raise the temperature to 100°C, slowly drop in polyether polyol, react for...

Embodiment 3

[0070] Embodiment 3: The difference from Embodiment 1 is that the inner side of the pipe body is provided with a thermal insulation material. According to parts by weight, the thermal insulation material includes the following components: 120 parts of urea, 20 parts of urea-formaldehyde resin adhesive, hair 5 parts of foaming agent, 5 parts of surfactant, 70 parts of fly ash, 40 parts of coal gangue fiber, SiO 2 40 parts, phosphorus oxychloride 20 parts, polyether polyol 20 parts, melamine 5 parts,

[0071] The preparation method of the thermal insulation material comprises the following steps,

[0072] S1: Weigh the corresponding components according to the parts by weight, put the urea-formaldehyde resin adhesive, foaming agent urea and surfactant into a glass beaker, and stir evenly with a high-speed stirrer to prepare a foam emulsion;

[0073] S2: Add phosphorus oxychloride to the foam emulsion and raise the temperature to 100°C, slowly drop in polyether polyol, react for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com