Preparation method of copper-baicalin complex, cobalt-baicalin complex and nickel-baicalin complex

A technology for baicalin and complexes, which is applied in the field of preparation of copper-cobalt-nickel-baicalin complexes, can solve the problems of many by-products, unstable baicalin, long precipitation time and the like, achieves high yield and purity, and accelerates precipitation. The effect of speed and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

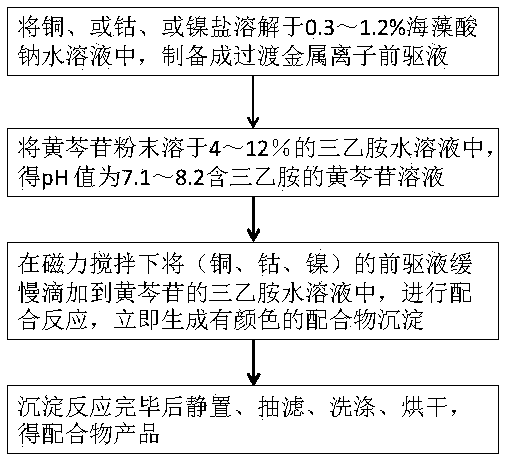

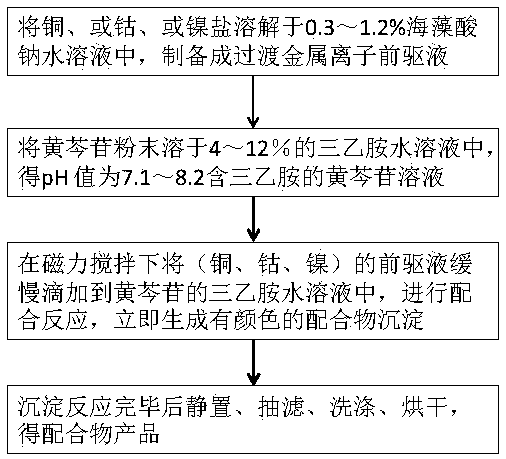

[0020] like figure 1 Shown, the present invention provides the preparation method of copper-cobalt-nickel transition metal-baicalin complex, it comprises the following steps:

[0021] S1. Preparation of copper (cobalt, or nickel) ion precursor: take copper salt compound such as Cu (Ac) 2 , CuCl 2 、CuSO 4 , Cu(NO 3 ) 2 , or cobalt salt compounds such as Co (Ac) 2 、CoCl 2 、CoSO 4 , Co(NO 3 ) 2 , or nickel salt compounds such as Ni (Ac) 2 、NiCl 2 、NiSO 4 , Ni(NO 3 ) 2 Dissolve in 0.2-0.9% sodium alginate aqueous solution to prepare transition metal ion precursor solution.

[0022] S2. Preparation of triethylamine aqueous solution of baicalin: taking baicalin powder and dissolving it in 4-12% triethylamine aqueous solution to obtain a triethylamine-containing baicalin solution with a pH value of 7.1-8.2.

[0023] S3. Slowly add the transition metal ion precursor solution obtained in S1 into the triethylamine aqueous solution of baicalin obtained in S2 under magneti...

Embodiment 1

[0026] Take baicalin powder and dissolve it with 100mL of 4% triethylamine aqueous solution to make 6.7mmol of baicalin solution, the pH value of this solution is 7.1; 8.04mmol copper acetate solution (containing 0.2% sodium alginate), the precipitate was obtained; continue to stir at room temperature for 2 hours, then let stand for 60 minutes, then filter, wash with 3% triethylamine aqueous solution for several times, and then distilled water Wash 5 times, and finally wash several times with 95% ethanol, and dry under vacuum at 70°C to obtain the copper-baicalin complex precipitation product.

[0027] The content of trace copper in the product was measured by atomic absorption spectrometry, and the yield and purity were calculated; the yield of the product was determined to be 98.72%, and the purity was 99.25%.

Embodiment 2

[0029] Take baicalin powder and dissolve it with 100mL of 12% triethylamine aqueous solution to make 6.7mmol of baicalin solution. The pH value of this solution is 8.2; 10.72 mmol copper sulfate solution (containing 0.9% sodium alginate), the precipitate was obtained; continue to stir at room temperature for 3 h, then let stand for 30 min, filter, wash with 6% triethylamine aqueous solution for several times, and then wash with distilled water 5 times, and finally washed several times with 95% ethanol, and dried under vacuum at 50°C to obtain the copper-baicalin complex precipitation product.

[0030] The content of trace copper in the product was measured by atomic absorption spectrometry, and the yield and purity were calculated; the yield of the product was determined to be 99.03%, and the purity was 99.14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com