ZTA ceramic material preparation method and material prepared from method

A technology for ceramic materials and raw materials, which is applied to the preparation method of ZTA ceramic materials and the field of materials prepared, can solve the problems of agglomeration, uneven size, and sequence errors, so as to improve the performance of the sintered body, enhance the sintering temperature, and improve the selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

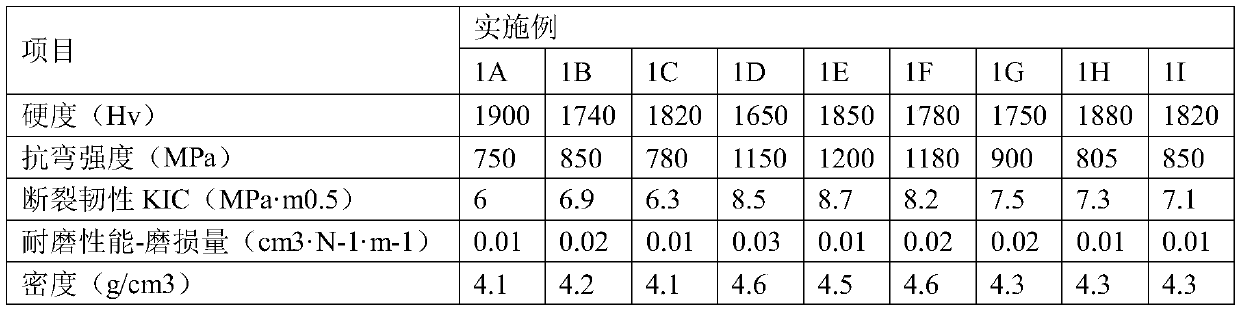

Embodiment 1

[0061] A kind of ZTA ceramic material, its composition comprises aluminum oxide, zirconium oxide and chromium oxide, and its preparation method is as follows,

[0062] S1: Prepare a 0.3mol / L chromium chloride solution with chromium chloride as raw material, slowly add ammonia water dropwise to the solution, adjust the pH value to 10-12, and stir for 2-5h to produce chromium hydroxide gel. After the obtained chromium hydroxide gel is repeatedly washed with high-purity water, it is dried at an ambient temperature of 60°C for subsequent use;

[0063] S2: Reacting excess high-purity metallic aluminum with 20% dilute hydrochloric acid, after filtering, purifying the obtained aluminum chloride with ion exchange resin and activated carbon to remove impurities to obtain an aluminum chloride solution;

[0064] S3: Distilling the aluminum chloride solution obtained in S2 under reduced pressure to obtain high-purity aluminum chloride powder;

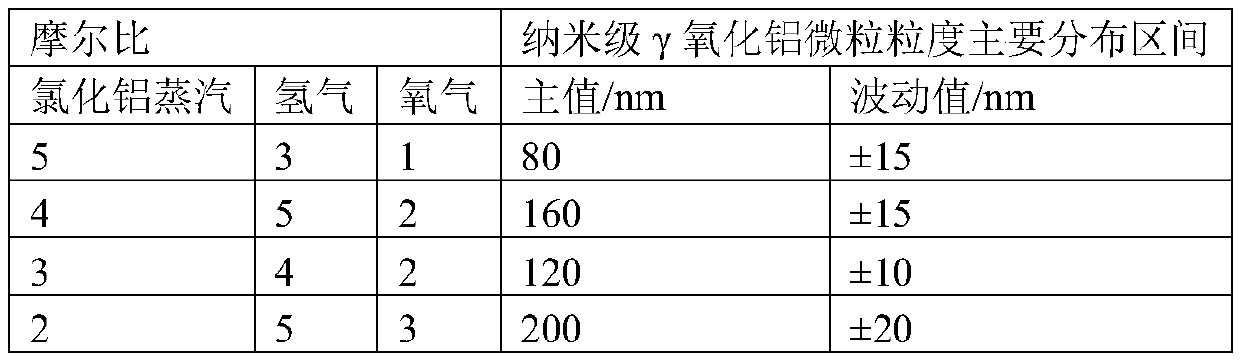

[0065] S4: Heat the high-purity aluminum ch...

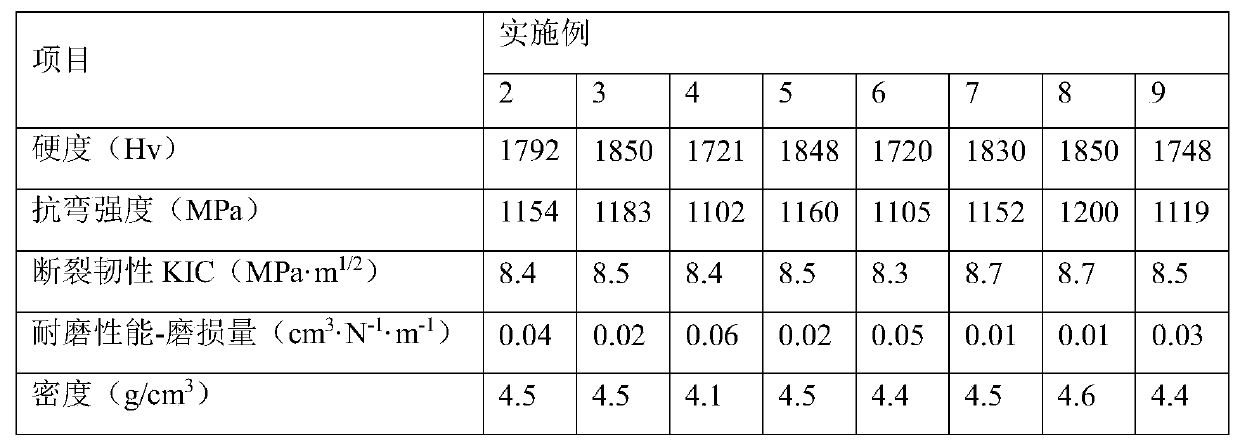

Embodiment 2

[0099] A ZTA ceramic material, based on the basis of Example 1E, the difference is that before heating the autoclave in S6, nanometer monoclinic zirconia seed crystals are no longer added to the autoclave, but the autoclave is directly heated To 150°C-250°C, pressurize the reactor to 3-5MPa, keep stirring for 2 hours, and filter to obtain nanometer 2Y hydrated zirconia gel particles.

Embodiment 3

[0101] A ZTA ceramic material, based on Example 1E, the difference is that in S1, a sodium hydroxide solution with a concentration of 20 wt% is used to adjust the pH value of the chromium chloride solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com