Collagen peptide, production method, production device and application thereof

The technology of a collagen peptide and its production method is applied in the field of collagen peptide and its production method and production equipment, which can solve the problems of poor water resolubility and easy moisture absorption of collagen peptide powder, and achieve excellent water resolubility and finished products Delicate, not easy to absorb moisture and agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] When the collagen peptide is used as a raw material for preparing effervescent tablets, the collagen peptide can be combined with high-quality calcium lactate to make a calcium source collagen peptide effervescent tablet, which can supplement calcium and help calcium deposition at the same time, and has a unique taste. Abundant nutrition, calcium supplementation from the source, healthy and "backbone", suitable for calcium supplementation crowd. Put a piece of Calcium Source Collagen Peptide Effervescent Tablet (4g) into about 200ml of water (both cold and warm water) effervescently dissolve and then drink.

[0062] When the collagen peptide is used as a raw material for the preparation of chewable tablets, the collagen peptide can be used as the nutritional basis, adding probiotics such as Lactobacillus rhamnosus, and scientifically formulated according to the golden ratio required by the human body. Chewable Probiotic Peptides. Chewing food, portable, refreshing tast...

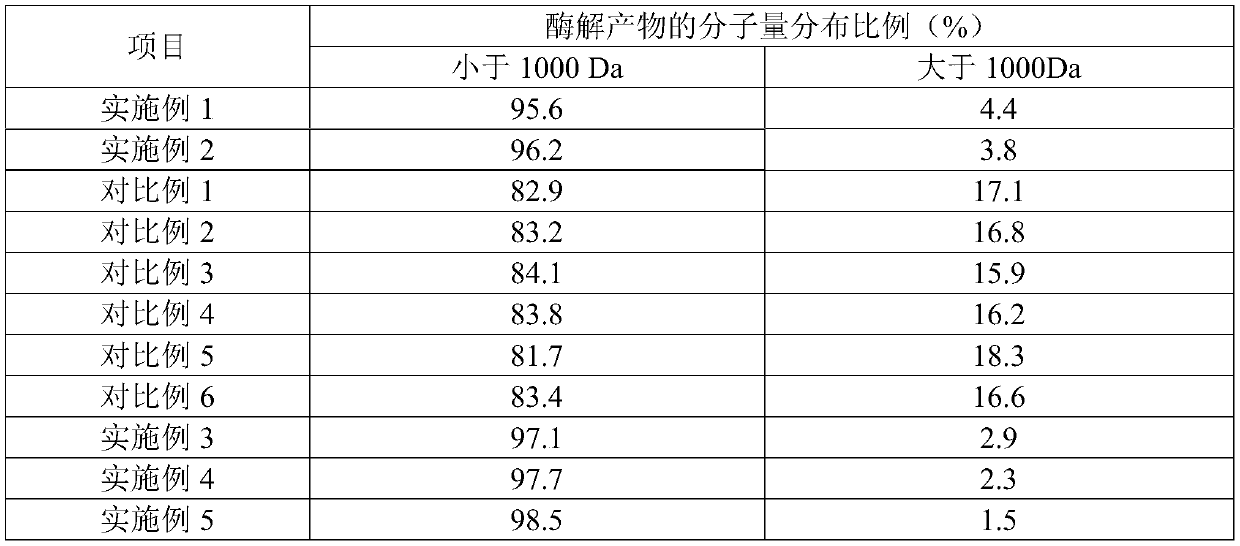

Embodiment 1

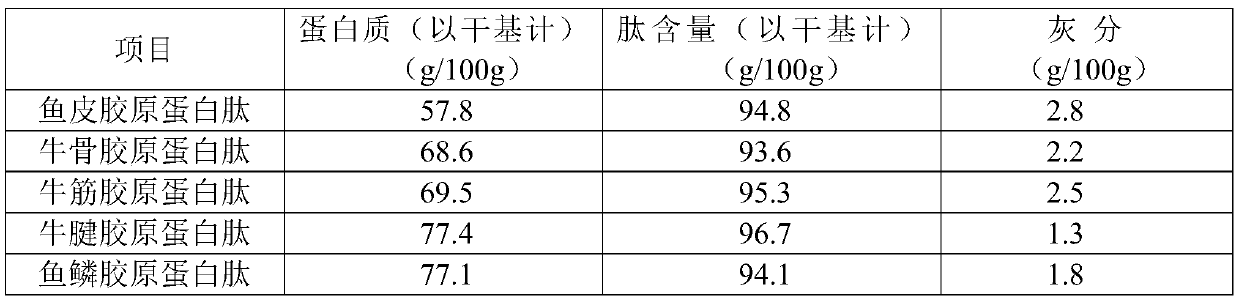

[0069] The production method of embodiment 1 fish skin collagen peptide

[0070] (1) Mix the crude collagen powder derived from fish skin with distilled water at a ratio of 1:3, then heat the obtained crude collagen solution at 100°C for 10 minutes, and then cool it down to 50-55°C to form a solution to be enzymatically hydrolyzed.

[0071] (2) Add 0.1% (w / w) crude collagen powder weight high-efficiency compound enzyme preparation to the enzymolysis solution, mix well and enzymolyze at natural pH value and natural temperature for 2 hours to obtain crude collagen protein peptide solution. The high-efficiency compound enzyme preparation consists of 25wt% composite protease, 30wt% alkaline protease, 15wt% neutral protease, 20wt% flavor protease, 7wt% animal proteolytic enzyme and 3wt% enzyme activator (dithiothreitol) Among them, the enzyme activities of the above proteases are all 200,000 u / g.

[0072] (3) The crude collagen peptide solution is filtered by a roll-type ultrafil...

Embodiment 2

[0076] The production method of embodiment 2 bovine bone collagen protein peptide

[0077] (1) Mix the crude collagen powder derived from bovine bone with distilled water at a ratio of 1:4, then heat the obtained crude collagen solution at 90°C for 20 minutes, and then cool it down to 50-55°C to prepare the enzymolysis solution.

[0078] (2) Add 0.15% (w / w) high-efficiency compound enzyme preparation of crude collagen powder weight to the enzymolysis solution, mix well and enzymolyze it at natural pH value and natural temperature for 2 hours to obtain crude collagen protein peptide solution. The high-efficiency compound enzyme preparation is composed of compound protease 27.5wt%, alkaline protease 27.5wt%, neutral protease 17.5wt%, flavor protease 17.5wt%, animal proteolytic enzyme 8wt% and enzyme activator (β-mercaptoethanol ) 2wt%, wherein, the enzyme activities of the above proteases are all 200,000 u / g.

[0079] (3) The crude collagen peptide solution is filtered with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com