Flame-retardant antibacterial coating for elevator and preparation method of coating

An antibacterial coating and elevator technology, applied in coatings, fire-resistant coatings, anti-fouling/underwater coatings, etc., can solve the problem that the car does not have the ability to prevent fire, water, and isolate smoke, is easily attacked by fireworks, and has low work efficiency. and other problems, to achieve superior flame retardant, anti-mildew and antibacterial properties, and improve product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

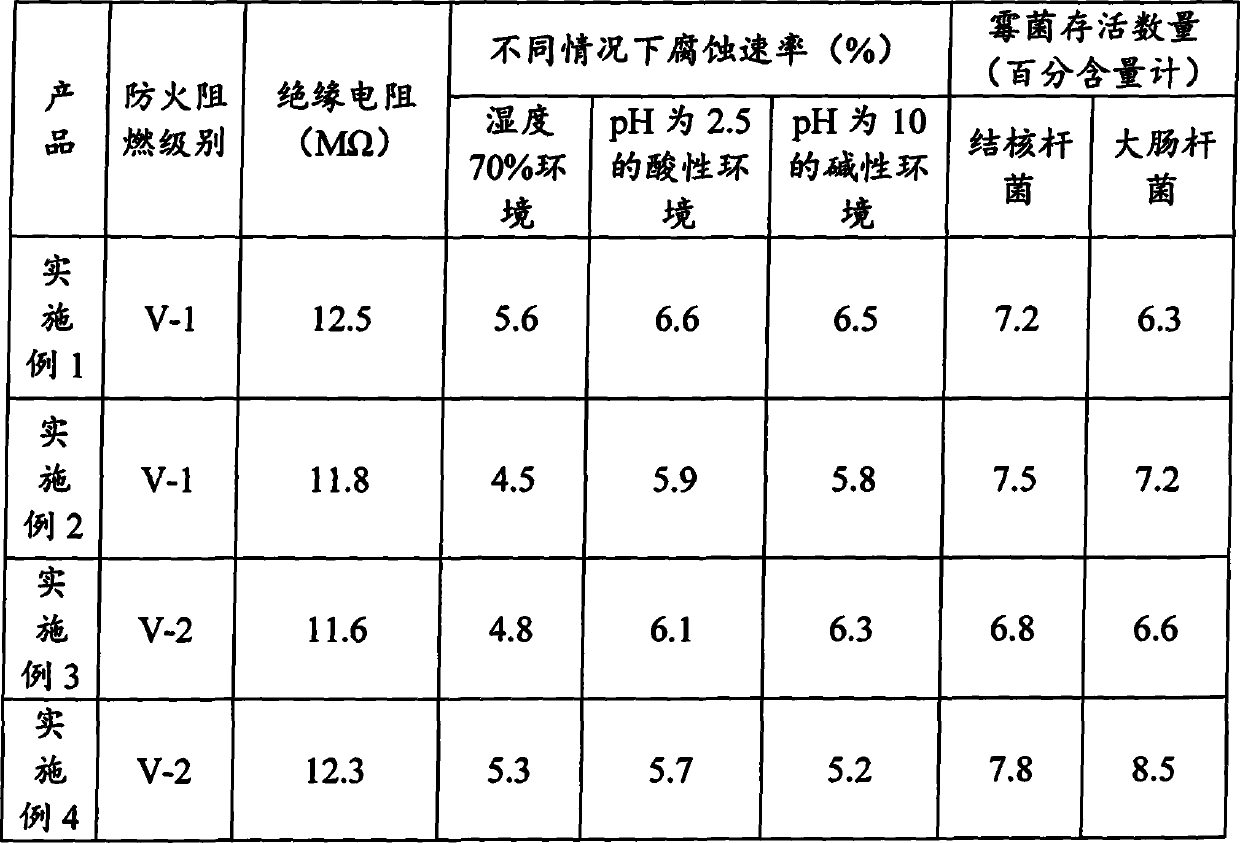

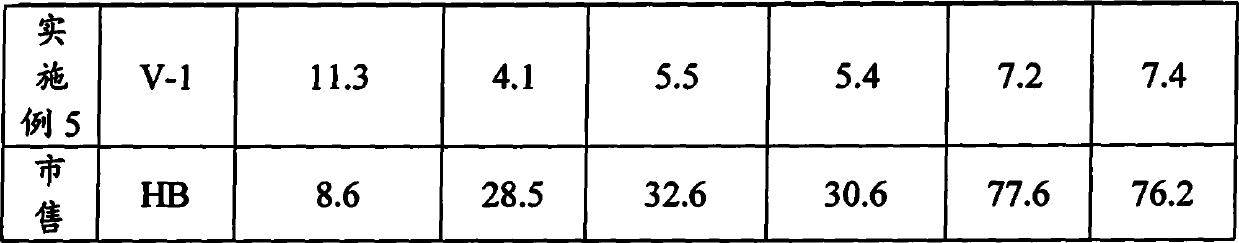

Examples

Embodiment 1

[0030] Flame retardant and antibacterial coatings for elevators:

[0031] (1) Mixing: Weigh 12g sodium diacetate, 10g triphenyl phosphate, 20g aluminum phosphide, 12g nano-modified bamboo charcoal, 12g nano-zinc oxide, 8g potassium sorbate, 26g graphite fiber, 10g PVC resin, aluminum hydroxide 3g powder, 10g magnesium hydroxide powder, 12g alumina powder, 12g quicklime powder, 20g paraffin, 12g sodium tetraborate, 18g pine smoke ink, 28g carbon tetrachloride, 24g terpineol, 5g dodecyl glucoside, Ethoxyquinoline 10g, polyhexamethylene biguanide hydrochloride 3g, the weighed raw materials were stirred at 2500r / min for 10min to obtain a homogeneous mixture;

[0032] (2) Calcining: Calcining the mixture obtained in step (1) at 500° C. for 30 min;

[0033] (3) Grinding and pulverizing: the mixture after the calcining described in step (2) is put into a grinder to grind for 10 min, and pass through a 40-mesh sieve;

[0034] (4) Ultrasonic dispersion: put the sieved mixture in step...

Embodiment 2

[0037] Flame retardant and antibacterial coatings for elevators:

[0038] (1) Mixing: Weigh 8g sodium diacetate, 15g triphenyl phosphate, 20g aluminum phosphide, 11g nano-modified bamboo charcoal, 16g nano-zinc oxide, 9g potassium sorbate, 25g graphite fiber, 6g PVC resin, aluminum hydroxide 3g powder, 15g magnesium hydroxide powder, 12g alumina powder, 18g quicklime powder, 20g paraffin, 12g sodium tetraborate, 14g pine smoke ink, 28g carbon tetrachloride, 28g terpineol, 10g dodecyl glucoside, Ethoxyquinoline 9g, polyhexamethylene biguanide hydrochloride 2g, the weighed raw materials were stirred at a speed of 3000r / min for 20min to obtain a uniformly mixed mixture;

[0039] (2) Calcining: Calcining the mixture obtained in step (1) at 600° C. for 60 min;

[0040] (3) Grinding and crushing: the mixture after the calcining in step (2) is put into a grinder to grind for 10 minutes, and pass through a 100-mesh sieve;

[0041] (4) Ultrasonic dispersion: put the sieved mixture in...

Embodiment 3

[0044] Flame retardant and antibacterial coatings for elevators:

[0045] (1) Mixing: Weigh 11g sodium diacetate, 13g triphenyl phosphate, 17g aluminum phosphide, 14g nano-modified bamboo charcoal, 12g nano-zinc oxide, 7g potassium sorbate, 25g graphite fiber, 11g PVC resin, aluminum hydroxide 5g powder, 12g magnesium hydroxide powder, 7g alumina powder, 16g quicklime powder, 17g paraffin, 13g sodium tetraborate, 15g pine smoke ink, 25g carbon tetrachloride, 26g terpineol, 9g dodecyl glucoside, Ethoxyquinoline 7g, polyhexamethylene biguanide hydrochloride 6g, the weighed raw materials were stirred at a speed of 3200r / min for 15min to obtain a uniformly mixed mixture;

[0046] (2) Calcining: Calcining the mixture obtained in step (1) at 650° C. for 60 min;

[0047] (3) Grinding and crushing: the mixture after the calcining described in step (2) is put into a grinder and ground for 15 minutes, and crosses an 80-mesh sieve:

[0048] (4) Ultrasonic dispersion: put the sieved mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com